Wall waterproofing is essential to protect buildings from moisture, seepage, and water damage. Over time, untreated walls can develop cracks, mold, and other structural problems that not only reduce the aesthetic appeal of a property but also weaken its foundation. To prevent these issues, wall waterproofing chemicals offer an effective solution. These chemicals create a protective barrier that keeps water out and ensures long-lasting durability for your walls.

In this article, we will explore the importance of wall waterproofing, the types of chemicals available, their benefits, and the application process.

Why Wall Waterproofing Is Crucial

Water infiltration can cause a range of problems, including:

Structural Damage: Continuous exposure to moisture weakens the structural integrity of walls, leading to cracks and deterioration.

Mold and Mildew Growth: Damp walls create an ideal environment for mold and mildew, which can negatively affect indoor air quality and lead to health issues such as allergies and respiratory problems.

Efflorescence: This is the white, powdery substance that appears on walls due to water seepage. Efflorescence not only looks unsightly but also indicates ongoing moisture problems.

Paint Peeling: Moisture causes paint to bubble, crack, and peel, reducing the visual appeal of walls.

Energy Efficiency Loss: Wet walls transfer heat more quickly, leading to higher energy costs for heating or cooling.

Proper waterproofing eliminates these risks, ensuring your walls remain dry and structurally sound.

Types of Wall Waterproofing Chemicals

There are several types of wall waterproofing chemicals, each designed to address specific needs. These include:

Cementitious Waterproofing:

One of the most commonly used methods.

Made from a blend of cement, sand, and waterproofing compounds.

Ideal for internal and external walls, as well as basements and water tanks.

Acrylic Waterproofing Solutions:

Made from acrylic polymers.

Provide excellent water resistance and flexibility.

Often used for decorative finishes on walls.

Bituminous Coatings:

Derived from asphalt, these coatings create a protective, water-resistant layer.

Commonly used for underground structures, retaining walls, and basements.

Polyurethane Waterproofing:

Known for its high elasticity and seamless finish.

Effective in covering cracks and preventing water seepage.

Best suited for areas exposed to direct sunlight and heavy rain.

Silicone-Based Water Repellents:

These are transparent solutions that penetrate the surface and repel water.

Ideal for preserving the natural appearance of walls.

Epoxy Waterproofing:

Offers superior adhesion and durability.

Commonly used in industrial applications and areas prone to heavy wear and tear.

Benefits of Wall Waterproofing Chemicals

Using wall waterproofing chemicals offers a multitude of advantages, including:

Enhanced Longevity: Waterproofing extends the lifespan of walls by preventing structural damage caused by moisture.

Improved Indoor Air Quality: By eliminating dampness and mold growth, waterproofing ensures healthier living conditions.

Cost-Effective Maintenance: Investing in waterproofing reduces the need for frequent repairs and repainting.

Energy Efficiency: Dry walls provide better insulation, helping to maintain indoor temperatures and lower energy bills.

Aesthetic Appeal: Waterproofing prevents paint peeling, stains, and efflorescence, keeping walls looking fresh and clean.

Property Value: Waterproofed walls enhance the overall value of a property by maintaining its structural integrity and appearance.

Steps for Applying Wall Waterproofing Chemicals

Proper application is critical to the effectiveness of wall waterproofing chemicals. Here’s a step-by-step guide:

Surface Preparation:

Clean the wall thoroughly to remove dust, dirt, grease, and loose paint.

Repair any cracks or holes using a suitable filler or patching compound.

Ensure the surface is dry and even.

Priming:

Apply a primer to improve the adhesion of the waterproofing chemical to the wall.

Use a brush, roller, or sprayer for even coverage.

Application of Waterproofing Chemical:

Depending on the type of chemical, apply it using a brush, roller, or spray gun.

Ensure even coverage and pay special attention to joints, corners, and edges.

Curing:

Allow the waterproofing layer to cure as per the manufacturer’s instructions. Curing time may vary based on the product and environmental conditions.

Final Coating (Optional):

For decorative finishes, apply a topcoat of paint or texture over the waterproofing layer.

Ensure the topcoat is compatible with the waterproofing chemical used.

Tips for Choosing the Right Waterproofing Chemical

Assess Your Needs:

Determine the extent of moisture problems and the type of wall (e.g., interior, exterior, underground).

Consider the Environment:

Choose a chemical that can withstand local weather conditions, such as heavy rain or extreme heat.

Compatibility:

Ensure the waterproofing chemical is compatible with the wall material, such as concrete, brick, or plaster.

Brand Reputation:

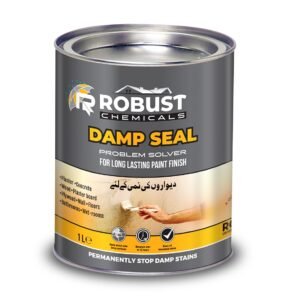

Opt for trusted brands known for quality and durability.

Eco-Friendliness:

Consider environmentally friendly products that are non-toxic and safe for indoor use.

Maintaining Waterproofed Walls

While waterproofing chemicals offer long-term protection, regular maintenance ensures their effectiveness:

Inspect Regularly:

Check walls for signs of damage, cracks, or discoloration.

Clean Walls:

Remove dirt and debris to maintain the protective layer.

Reapply as Needed:

Depending on the chemical used, reapply waterproofing every few years to ensure continued protection.

Address Issues Promptly:

Fix any leaks, plumbing problems, or damaged areas immediately to prevent further damage.