Thermal Shield for Heat Insulation

In a world where energy efficiency is becoming more critical, the importance of insulation cannot be overstated. Whether you’re aiming to make your home more energy-efficient or looking to reduce cooling costs in industrial spaces, thermal insulation is a pivotal solution. One of the key technologies in this field is the thermal shield, a specialized material or system designed to protect against heat transfer, keeping environments cooler and more comfortable.

In this guide, we will explore the concept of thermal shields, their applications, and the science behind them, along with why they are such a crucial component of heat insulation strategies in modern building and industrial practices.

What Is a Thermal Shield?

A thermal shield is a barrier material used to reduce or prevent the transfer of heat from one area to another. This can be used in various environments—residential, commercial, and industrial—where thermal regulation is essential. Thermal shields act as a defense against external heat sources, like the sun, or internal ones, such as machinery or other heat-generating systems.

Typically, thermal shields are composed of materials with high reflectivity and low thermal conductivity, meaning they reflect most of the heat energy and don’t easily transmit heat through them. These properties make thermal shields excellent at maintaining temperature consistency within a space, reducing the need for artificial cooling or heating systems, and ultimately lowering energy consumption.

The Science Behind Heat Insulation

To understand how thermal shields work, it’s essential to know a bit about heat transfer. Heat can move in three ways:

- Conduction: This is the transfer of heat through a solid material. For instance, when a metal spoon becomes hot after being left in a pot of boiling water, that’s conduction.

- Convection: This type of heat transfer occurs in liquids or gases. When air or water is heated, it becomes less dense and rises, creating a circulation of heat.

- Radiation: Heat transfer by radiation involves the emission of energy in the form of electromagnetic waves. The most common form of heat radiation is from the sun.

Thermal shields are designed to minimize all three types of heat transfer, with a primary focus on radiation and conduction. High-reflective materials help to bounce away radiant heat, while low-conductive materials slow down heat transfer through conduction.

Applications of Thermal Shields

Thermal shields are versatile and used in various settings. Below are some common applications:

1. Residential Buildings

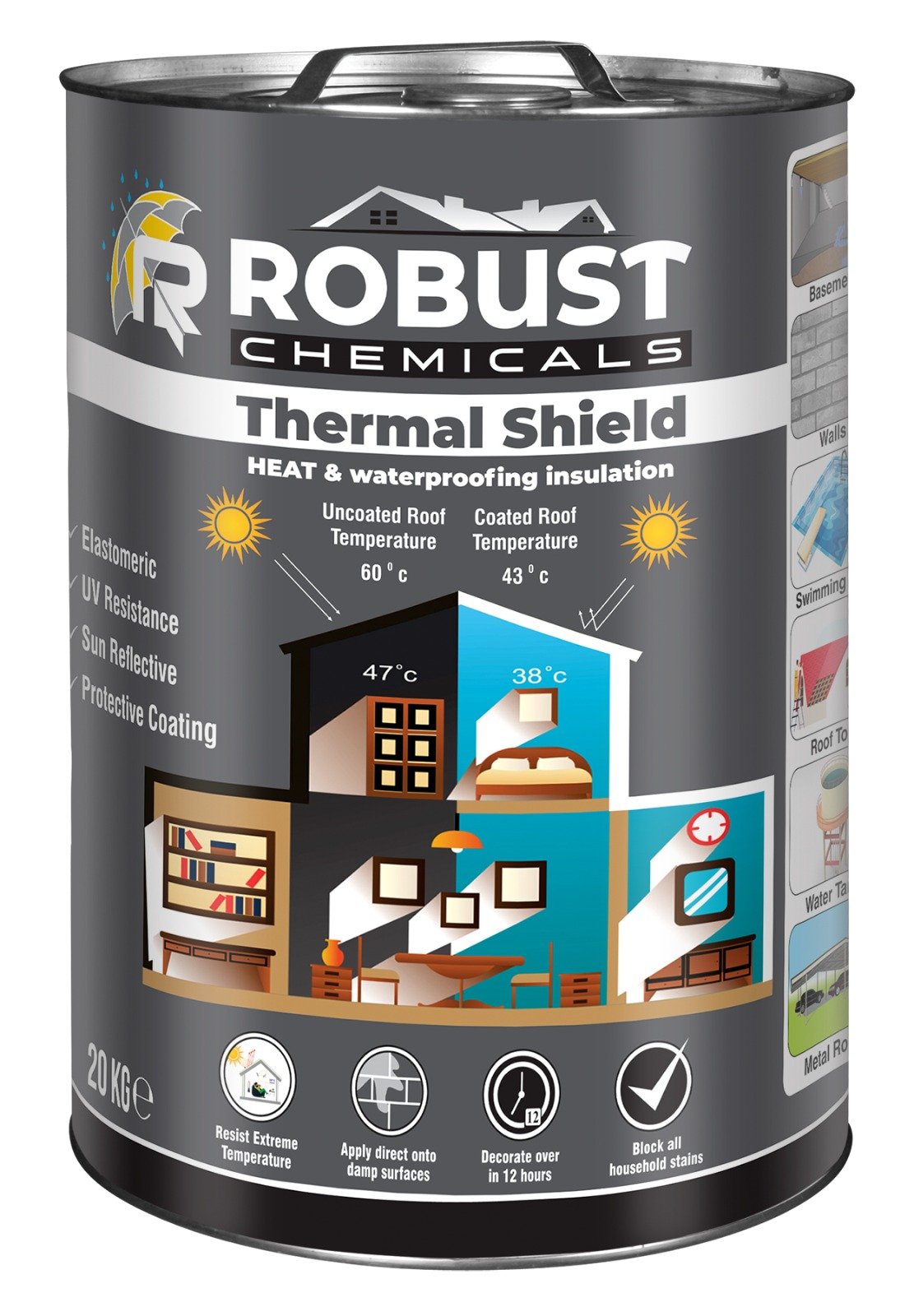

One of the primary uses of thermal shields is in homes, particularly in attics, walls, and roofs. By installing thermal shields in these areas, homeowners can significantly reduce the amount of heat that enters during the summer and escapes during the winter, keeping the interior at a more stable temperature year-round. This leads to lower utility bills, as the demand for heating and cooling systems decreases.

Thermal shields are often incorporated into roof insulation or placed as radiant barriers in attics. During hot weather, the sun’s heat can cause the attic space to become excessively warm, which in turn transfers heat into the living areas. A properly installed thermal shield will reflect a significant amount of that radiant heat, keeping the home cooler.

2. Commercial Buildings

Large commercial buildings such as office complexes, shopping malls, and factories also benefit from thermal shields. Commercial spaces often have large surface areas exposed to the sun, and air conditioning can become a significant cost. By applying thermal shields to roofs, windows, and walls, businesses can create more energy-efficient environments, resulting in lower operational costs.

3. Industrial Settings

In industrial applications, thermal shields play a critical role in heat management. Many industries have processes that generate intense heat, such as manufacturing plants, power generation, and refineries. In these settings, thermal shields are used to protect workers from heat, safeguard machinery from overheating, and reduce energy consumption by controlling internal temperatures.

In addition, thermal shields are used in cold storage facilities where keeping temperatures low is crucial. They help maintain the cold by minimizing heat ingress, ensuring energy efficiency.

4. Automotive and Aerospace Industries

Thermal shields are vital in vehicles and spacecraft. In the automotive industry, these shields protect components like engines, exhaust systems, and interiors from excessive heat, improving performance and safety. In aerospace, thermal shields are essential for spacecraft and satellites to withstand the extreme temperatures experienced during launch and re-entry.

5. Greenhouses and Agriculture

In agriculture, controlling temperature is crucial for plant growth. Thermal shields are used in greenhouses to manage heat gain during the day and heat loss at night, creating an optimal environment for crops. By using these shields, farmers can extend growing seasons and reduce the need for artificial climate control.

Benefits of Using Thermal Shields

The adoption of thermal shields for heat insulation provides numerous advantages, making them an essential investment for energy-conscious individuals and industries.

1. Energy Efficiency

Perhaps the most significant benefit is the reduction in energy consumption. By reflecting and blocking heat, thermal shields lower the amount of work that air conditioning systems need to do in the summer and heating systems in the winter. This leads to substantial savings on utility bills, especially in climates with extreme temperature fluctuations.

2. Comfort

Thermal shields maintain a consistent and comfortable indoor temperature. Whether in a home, office, or industrial plant, the reduction in heat transfer creates a more pleasant environment, reducing the need for constant temperature adjustments and enhancing overall comfort.

3. Protection of Structures

Thermal shields also provide structural protection. By minimizing heat exposure, they can extend the lifespan of building materials, reducing wear and tear caused by thermal expansion and contraction. This is particularly valuable in hot climates where constant sun exposure can degrade roofs, walls, and other parts of a building.

4. Environmental Impact

By reducing energy consumption, thermal shields contribute to lower greenhouse gas emissions, playing a role in environmental sustainability. They help decrease reliance on fossil fuels for heating and cooling, contributing to a greener, more eco-friendly future.

Types of Thermal Shields

Thermal shields come in various forms, each designed for specific applications:

- Reflective Foil Insulation: Often used in attics or on walls, this type of shield reflects radiant heat.

- Ceramic Coatings: These are sprayed onto surfaces to provide thermal insulation and are often used in industrial applications.

- Fiberglass Insulation: While primarily known for its use in traditional insulation, fiberglass can also be part of a thermal shield system.

- Aerogel Insulation: Known for being one of the best insulating materials, aerogel is used in extreme environments like spacecraft due to its superior thermal performance.

Thermal Shield for Heat Insulation

1. Introduction

In the modern world, thermal insulation plays a vital role in a wide range of applications—from protecting spacecraft and aircraft from extreme temperatures to improving the energy efficiency of buildings, vehicles, and industrial systems. The concept of a thermal shield is central to heat management in these systems. A thermal shield refers to a layer or structure specifically designed to reduce or prevent heat transfer between regions of differing temperatures. These shields are engineered using materials and configurations that offer high resistance to conduction, convection, and radiation, depending on the application.

The importance of thermal shields is underscored by their contribution to energy conservation, material protection, and safety enhancement. For instance, in aerospace engineering, thermal shields protect spacecraft from the intense heat generated during atmospheric re-entry. In industrial and architectural contexts, insulation shields reduce heat loss, lowering energy costs and carbon emissions. This paper explores the principles, materials, types, and applications of thermal shields for heat insulation, along with design considerations and recent technological advancements.

2. Principles of Heat Transfer

To understand the function of thermal shields, it is necessary to examine the mechanisms of heat transfer: conduction, convection, and radiation.

2.1 Conduction

Conduction is the process of heat transfer through a solid medium due to molecular vibration and electron movement. The rate of conductive heat transfer can be described by Fourier’s Law:

Q=−kAdTdxQ = -kA \frac{dT}{dx}

Where:

-

QQ = heat transfer rate (W)

-

kk = thermal conductivity of the material (W/m·K)

-

AA = cross-sectional area (m²)

-

dTdx\frac{dT}{dx} = temperature gradient (K/m)

Materials with low thermal conductivity, such as ceramics or aerogels, are ideal for thermal shields, as they restrict the flow of heat through conduction.

2.2 Convection

Convection involves heat transfer through fluid motion, typically air or liquid, and is governed by Newton’s Law of Cooling:

Q=hA(Ts−T∞)Q = hA(T_s – T_\infty)

Where:

-

hh = convective heat transfer coefficient (W/m²·K)

-

TsT_s = surface temperature

-

T∞T_\infty = ambient fluid temperature

Thermal shields often use trapped air layers or vacuum gaps to minimize convective heat transfer.

2.3 Radiation

Thermal radiation is the emission of electromagnetic waves, mainly in the infrared spectrum, by all bodies above absolute zero. The net radiative heat transfer between two surfaces is given by the Stefan–Boltzmann Law:

Q=ϵσA(T14−T24)Q = \epsilon \sigma A (T_1^4 – T_2^4)

Where:

-

ϵ\epsilon = emissivity of the surface

-

σ\sigma = Stefan–Boltzmann constant (5.67×10⁻⁸ W/m²·K⁴)

Highly reflective materials like aluminum or gold coatings are used in thermal shields to reduce radiative heat transfer.

3. Materials for Thermal Shields

The selection of materials is a critical aspect of thermal shield design. The material must withstand high temperatures, resist degradation, and provide efficient insulation.

3.1 Metallic Materials

Metals such as aluminum, titanium, and stainless steel are commonly used due to their structural strength and ability to reflect thermal radiation. Aluminum, in particular, has high reflectivity and is lightweight, making it suitable for aerospace applications. However, metals generally have high thermal conductivity, so they are often combined with insulating layers.

3.2 Ceramic Materials

Ceramics like silica, zirconia, and alumina offer excellent thermal stability and low thermal conductivity. They can withstand temperatures exceeding 1500°C and are widely used in high-temperature environments, such as rocket engines and re-entry vehicles. Ceramic matrix composites (CMCs) further enhance mechanical strength and fracture resistance.

3.3 Polymer-Based Materials

Polymers such as polyimide, epoxy, and phenolic resins are utilized in moderate-temperature insulation systems. They are lightweight and flexible, making them suitable for applications like insulation blankets or coatings. However, their use is limited by thermal degradation at high temperatures.

3.4 Aerogels

Aerogels are among the most effective thermal insulating materials known today. Composed of over 90% air, silica aerogels exhibit extremely low thermal conductivity (as low as 0.013 W/m·K). They are used in both industrial insulation and space missions, such as NASA’s Mars rovers.

3.5 Ablative Materials

Ablative materials are designed to absorb and dissipate heat through controlled material erosion. As the surface ablates, it carries away thermal energy, protecting the underlying structure. Phenolic impregnated carbon ablator (PICA) is a well-known example used on the SpaceX Dragon and NASA’s Orion capsules.

4. Design of Thermal Shields

The effectiveness of a thermal shield depends not only on the material but also on its design architecture. The following design approaches are commonly employed:

4.1 Layered Insulation

Multi-layer insulation (MLI) systems use alternating layers of reflective and insulating materials to minimize heat transfer. Each reflective layer reduces radiation, while the spacer layers minimize conduction and convection. MLI is the standard for spacecraft thermal protection.

4.2 Honeycomb and Foam Structures

Porous structures like honeycombs or foams trap air within cells, greatly reducing conduction and convection. These structures are lightweight and provide structural strength.

4.3 Thermal Barrier Coatings (TBCs)

TBCs are thin ceramic coatings applied to metal components in engines and turbines. They act as barriers against high temperatures and oxidation, extending component lifespan. Typical TBC materials include yttria-stabilized zirconia (YSZ).

4.4 Phase Change Materials (PCMs)

PCMs absorb or release heat during phase transitions (e.g., melting or solidifying) without large temperature changes. They are used in thermal shields for spacecraft and electronics cooling to manage transient heat loads.

4.5 Active Thermal Control Systems

In high-performance systems, passive insulation is sometimes insufficient. Active thermal shields use fluid circulation, heat pipes, or thermoelectric coolers to actively manage heat. These are common in satellites and high-power electronics.

5. Applications of Thermal Shields

Thermal shields are utilized across numerous industries, each with unique thermal challenges and performance requirements.

5.1 Aerospace and Spacecraft

The aerospace sector has perhaps the most demanding thermal insulation needs. Spacecraft re-entering the Earth’s atmosphere encounter temperatures exceeding 1600°C due to aerodynamic heating. Thermal shields made from ablative or ceramic materials protect the craft from destruction. For example:

-

Apollo Command Modules used ablative heat shields made from phenolic resins.

-

Space Shuttle tiles were made of silica-based ceramics.

-

SpaceX Dragon employs PICA-X, an advanced reusable ablative material.

In satellites and deep-space probes, thermal shields protect instruments from both solar radiation and the extreme cold of space using multi-layer insulation.

5.2 Automotive and Transportation

In automotive engineering, thermal shields prevent heat damage from exhaust systems, engines, and brakes. They also enhance passenger comfort and improve vehicle efficiency. Aluminum-coated glass fiber composites are widely used in exhaust heat shields.

5.3 Building and Construction

Thermal insulation in buildings helps maintain interior temperatures, reduce energy consumption, and enhance comfort. Reflective barriers, foam boards, and mineral wool are common examples. Modern architectural designs also use vacuum insulation panels (VIPs) for superior thermal performance.

5.4 Industrial Equipment

High-temperature processes such as furnaces, kilns, and reactors require thermal shields to protect equipment and operators. Ceramic fiber blankets and refractory linings are standard in such environments.

5.5 Electronics and Energy Systems

In electronics, thermal shielding prevents overheating of sensitive components. Similarly, in renewable energy systems like concentrated solar power (CSP) plants, thermal insulation improves energy capture efficiency.

6. Performance Evaluation

Evaluating the performance of a thermal shield involves assessing parameters such as thermal conductivity, emissivity, temperature resistance, and durability.

6.1 Thermal Conductivity

Lower thermal conductivity indicates better insulation performance. Standard tests, such as ASTM C518 (Heat Flow Meter Method), are used to measure this property.

6.2 Emissivity and Reflectivity

Emissivity affects how much thermal radiation a material emits or absorbs. Coatings with low emissivity (e.g., metallic foils) are used for radiation control.

6.3 Thermal Shock Resistance

Thermal shields must endure rapid temperature changes without cracking or delaminating. This is especially critical in aerospace and turbine applications.

6.4 Mechanical and Environmental Durability

Factors such as vibration, oxidation, corrosion, and moisture exposure influence long-term performance. Composite and ceramic materials are often chosen for their superior resistance.

7. Advances in Thermal Shield Technology

Research continues to push the boundaries of thermal insulation materials and designs. Several emerging technologies stand out:

7.1 Nanostructured Materials

Nanomaterials such as carbon nanotubes, graphene aerogels, and nano-ceramic composites offer exceptional thermal and mechanical properties. They can be engineered for low thermal conductivity while maintaining strength and flexibility.

7.2 Reusable Thermal Protection Systems

Traditional ablative shields are single-use. Recent developments focus on reusable materials, like reinforced carbon-carbon composites and advanced ceramics, reducing mission costs.

7.3 Smart Insulation Systems

Smart thermal shields incorporate sensors and adaptive materials that change thermal properties in response to environmental conditions. Examples include variable emissivity coatings and thermochromic materials.

7.4 Additive Manufacturing

3D printing allows for complex geometries and tailored porosity in thermal shield components, improving performance while reducing weight and manufacturing costs.

8. Environmental and Energy Implications

The role of thermal insulation extends beyond performance—it also has significant environmental and economic implications. Effective thermal shielding:

-

Reduces energy consumption in buildings and vehicles.

-

Decreases greenhouse gas emissions.

-

Extends equipment lifespan, reducing waste and material use.

For instance, in industrial furnaces, improved insulation can cut energy losses by up to 30%. In buildings, efficient thermal barriers can lower heating and cooling costs by 40% or more. As global energy demand rises, optimizing thermal insulation remains a key strategy for sustainable development.

9. Challenges and Future Directions

Despite significant progress, several challenges remain in thermal shield development:

-

Balancing lightweight design with thermal performance.

-

Enhancing reusability and durability under extreme conditions.

-

Reducing manufacturing costs of advanced materials like aerogels and composites.

-

Developing eco-friendly materials with minimal environmental impact.

Future research aims to integrate multifunctional properties—such as self-healing, electrical conductivity, and radiation protection—into a single thermal shield system. The convergence of materials science, nanotechnology, and computational modeling will continue to drive innovation in this field.

10. Conclusion

Thermal shields are indispensable components in the management of heat across diverse industries—from aerospace to construction. By controlling conduction, convection, and radiation, they ensure safety, efficiency, and sustainability in systems exposed to extreme thermal environments. The evolution of materials—from ceramics and polymers to nanocomposites and aerogels—has dramatically improved their performance.

Looking forward, the demand for lighter, more efficient, and environmentally responsible insulation technologies will continue to rise. Advances in smart materials and additive manufacturing promise the next generation of adaptive, high-performance thermal shields. Ultimately, as both energy efficiency and sustainability become global priorities, thermal shielding will remain a cornerstone of engineering innovation and environmental responsibility.