- Robust Admin

- November 18, 2024

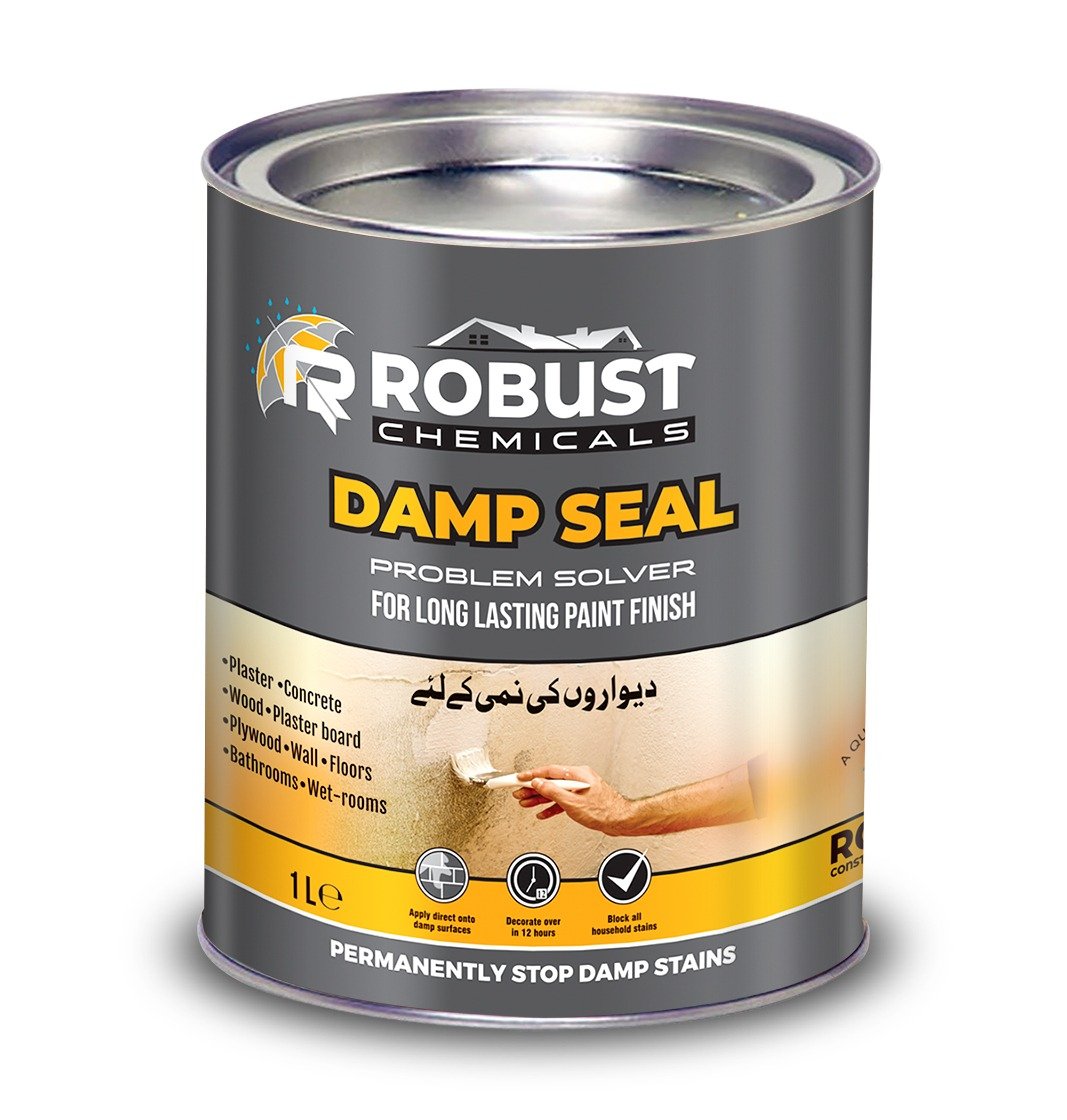

₨ 2,500 Original price was: ₨ 2,500.₨ 2,000Current price is: ₨ 2,000.

Robust Damp Seal is a high-quality waterproofing solution that effectively prevents dampness and moisture penetration in walls and surfaces. Easy to apply and fast-drying, it provides long-lasting protection against water damage, mold, and mildew, making it an essential product for maintaining and preserving buildings. Ideal for use on brick, plaster, and concrete surfaces.

Robust Damp Seal Coating | Advanced Waterproofing Protection by Robust Construction Chemicals

Meta Description:

Stop dampness and wall seepage with Robust Damp Seal Coating from Robust Construction Chemicals. Advanced formula ensures lasting waterproof protection and surface strength for every structure.

1. Introduction – The Ultimate Protection Against Dampness

In construction, one of the most common and damaging issues is dampness and water seepage. Whether in residential homes, commercial buildings, or industrial facilities, unchecked moisture leads to peeling paint, structural damage, mold growth, and reduced lifespan of concrete and plastered surfaces.

To address these challenges, Robust Construction Chemicals introduces Robust Damp Seal Coating, a premium waterproofing solution formulated with advanced polymers and chemical binders. It is specially designed to seal and protect surfaces exposed to moisture, ensuring long-term durability and an attractive, clean finish.

2. What is Robust Damp Seal Coating?

Robust Damp Seal Coating is a high-performance waterproofing coating designed to block dampness, resist efflorescence, and stop seepage from both interior and exterior walls. It forms a flexible, breathable membrane over the surface that prevents water penetration while allowing trapped moisture vapor to escape — ensuring the surface stays dry and intact.

It can be used on cement plaster, concrete, brick masonry, and other absorbent substrates. When applied correctly, it provides an excellent barrier against damp patches, fungus, and peeling paint, making it one of the most effective damp-proof coatings available today.

3. Composition and Technical Overview

Robust Damp Seal Coating is formulated using acrylic polymer emulsion, fine fillers, additives, and anti-fungal agents that enhance adhesion, flexibility, and UV resistance.

Technical Features:

-

Type: Acrylic-based waterproof coating

-

Appearance: White viscous liquid (dries to a semi-gloss or matte finish)

-

Mixing Ratio: Single-component ready-to-use or two-part system (as required)

-

Density: 1.35 ± 0.05 g/cc

-

Coverage: 1–1.5 m²/kg per coat (depending on surface texture)

-

Drying Time: Touch dry in 30–45 minutes; recoatable after 4–6 hours

-

Full Cure: 72 hours

-

Application Tools: Brush, roller, or spray machine

4. Key Benefits of Robust Damp Seal Coating

1. Superior Waterproofing

Forms a dense film that effectively blocks water penetration through walls, ceilings, and foundations.

2. Excellent Adhesion

Adheres strongly to cement, plaster, brick, and concrete, ensuring lasting protection.

3. Breathable Membrane

Allows moisture vapor to escape while preventing liquid water from entering — avoiding paint blistering.

4. UV & Weather Resistance

Maintains color stability and protection even under harsh sunlight and heavy rain.

5. Anti-Fungal & Algae Resistant

Contains bio-resistant additives that prevent black patches, algae, and fungus growth.

6. Crack Bridging Ability

Flexible coating bridges hairline cracks and prevents surface deterioration.

7. Cost-Effective

Long-lasting durability means fewer maintenance cycles and lower long-term costs.

5. Areas of Application

Robust Damp Seal Coating is suitable for interior and exterior waterproofing across multiple surfaces:

-

Interior walls affected by rising dampness

-

Exterior walls exposed to rain and moisture

-

Basements and foundations where water ingress is common

-

Roof slabs and parapet walls

-

Bathrooms and kitchens (above tile height or non-immersed areas)

-

Water tanks and sumps (outer surfaces)

-

Cement plastered surfaces before paint application

6. Surface Preparation – The Foundation of Success

Before applying Robust Damp Seal Coating, ensure the substrate is properly prepared.

Step 1: Clean the surface thoroughly — remove dust, dirt, oil, and loose particles.

Step 2: Repair cracks using Robust Crack Filler or polymer-modified mortar.

Step 3: Ensure the surface is slightly damp but not wet before coating.

Step 4: For best results, apply Robust Primer if the substrate is too porous.

A well-prepared surface ensures maximum adhesion and long-term waterproofing performance.

7. Application Instructions

Step 1: Mixing

If supplied as a single component, stir thoroughly before use. For two-part systems, mix base and liquid components in the recommended ratio until a uniform consistency is achieved.

Step 2: Application

-

Apply the first coat using a brush, roller, or spray.

-

Allow it to dry for 4–6 hours.

-

Apply the second coat perpendicular to the first for uniform coverage.

-

Maintain consistent film thickness across the surface.

Step 3: Drying & Curing

Allow the coating to dry completely for 48–72 hours before exposure to water. Avoid applying under direct sunlight or heavy rain conditions.

8. Coverage and Consumption

Coverage depends on substrate porosity, surface texture, and application thickness.

| Application Area | Average Coverage | Recommended Coats |

|---|---|---|

| Interior Walls | 1.5 m²/kg/coat | 2 |

| Exterior Walls | 1.2 m²/kg/coat | 2–3 |

| Roofs / Parapets | 1.0 m²/kg/coat | 3 |

9. Storage and Shelf Life

-

Store in a cool, dry place away from direct sunlight.

-

Keep container tightly closed when not in use.

-

Shelf Life: 12 months in unopened condition.

10. Safety Precautions

-

Avoid contact with skin and eyes; use gloves and goggles.

-

Ensure adequate ventilation during application.

-

In case of skin contact, wash immediately with soap and water.

-

Do not mix with cement or other chemicals unless recommended.

11. Comparison: Robust Damp Seal Coating vs Other Coatings

| Feature | Robust Damp Seal | Bitumen Coating | PU Coating |

|---|---|---|---|

| Base Material | Acrylic Polymer | Bituminous | Polyurethane |

| Breathability | ✅ High | ❌ Low | ✅ Medium |

| UV Resistance | ✅ Excellent | ❌ Poor | ✅ Good |

| Aesthetic Finish | ✅ Paintable | ❌ Black | ✅ Glossy |

| Application Ease | ✅ Simple | ⚠️ Messy | ⚠️ Skill-Dependent |

| Odor / VOC | ✅ Low | ❌ Strong | ⚠️ Moderate |

| Recoating | ✅ Easy | ❌ Difficult | ⚠️ Moderate |

Conclusion:

Robust Damp Seal Coating offers the perfect balance of breathability, flexibility, and UV stability, outperforming conventional bitumen coatings while being more economical than PU-based systems.

12. Advantages for Builders and Homeowners

-

Enhances paint durability and aesthetic appeal

-

Reduces maintenance costs

-

Prevents mold and mildew growth

-

Extends structure lifespan

-

Compatible with most decorative paints

-

Environmentally friendly and low VOC

Whether you are a contractor, engineer, or homeowner, choosing Robust Damp Seal Coating means investing in a durable and reliable waterproofing solution backed by the Robust Construction Chemicals reputation for excellence.

13. Real-World Applications & Case Studies

Residential Buildings:

Used on interior damp walls before repainting, eliminating moisture stains and efflorescence.

Commercial Projects:

Ideal for facade waterproofing and protection of exposed plaster surfaces in malls, schools, and offices.

Industrial Sheds:

Prevents corrosion and damp-induced surface deterioration.

Infrastructure Works:

Applied on retaining walls, basements, and podium slabs for moisture resistance.

14. Maintenance and Recoating

Routine inspection every 3–5 years ensures coating integrity. If minor wear or discoloration appears, a single recoating with Robust Damp Seal Coating restores full protection without removing the existing layer.

15. Environmental Benefits

Robust Damp Seal Coating is eco-friendly, solvent-free, and non-toxic. It contains low VOCs, making it safe for interior use and compliant with modern green building standards.

16. Frequently Asked Questions (FAQs)

Q1: Can it be painted over?

Yes, once fully cured, it can be painted with emulsion or acrylic paints.

Q2: Is it suitable for underground areas?

Yes, it provides excellent damp-proof protection for basements and retaining walls.

Q3: How long does it last?

With proper application, the coating lasts 8–10 years depending on exposure conditions.

Q4: Can it be applied over old paint?

No. Remove loose paint and prepare a clean, stable surface before application.

Q5: Can it resist salt efflorescence?

Yes, the formulation helps prevent white salt deposits from emerging on the surface.

17. Conclusion

Robust Damp Seal Coating stands as a comprehensive waterproofing solution that blends science, performance, and reliability. Its advanced acrylic polymer technology ensures deep protection against dampness, efflorescence, and wall seepage — all while maintaining breathability and aesthetics.

When used as part of a Robust Construction Chemicals waterproofing system, it enhances structural life, ensures lasting beauty, and delivers peace of mind for years.

Description

Robust Damp Seal Coating | Advanced Waterproofing Protection by Robust Construction Chemicals

Robust Damp Seal is a high-performance, waterproofing solution designed to protect buildings from moisture-related damage. Ideal for use on interior and exterior walls, it effectively seals damp areas, preventing further water penetration and the formation of unsightly mold or mildew. The product is specially formulated to create a durable barrier that resists moisture and condensation, safeguarding surfaces against the destructive effects of dampness over time. Its easy-to-apply, fast-drying nature makes it a convenient choice for both professional and DIY users. Whether you’re dealing with rising damp in basements, water leaks through walls, or simply seeking preventative moisture protection, Robust Damp Seal provides long-lasting protection and peace of mind. Its versatility allows it to be applied on various surfaces including brick, plaster, and concrete, making it an essential tool for home maintenance and building preservation.

Key Features:

Waterproof Protection: Prevents moisture and water ingress from external sources.

Mold & Mildew Resistant: Reduces the growth of harmful fungi that can damage structures and affect health.

Durable & Long-lasting: Offers a tough, flexible seal that withstands harsh environmental conditions.

Easy Application: Suitable for both professionals and DIY enthusiasts.

Multi-Surface Compatibility: Works on a wide range of surfaces including brick, concrete, and plaster.

Robust Damp Seal Coating | Advanced Waterproofing Protection by Robust Construction Chemicals

Meta Description:

Stop dampness and wall seepage with Robust Damp Seal Coating from Robust Construction Chemicals. Advanced formula ensures lasting waterproof protection and surface strength for every structure.

1. Introduction – The Ultimate Protection Against Dampness

In construction, one of the most common and damaging issues is dampness and water seepage. Whether in residential homes, commercial buildings, or industrial facilities, unchecked moisture leads to peeling paint, structural damage, mold growth, and reduced lifespan of concrete and plastered surfaces.

To address these challenges, Robust Construction Chemicals introduces Robust Damp Seal Coating, a premium waterproofing solution formulated with advanced polymers and chemical binders. It is specially designed to seal and protect surfaces exposed to moisture, ensuring long-term durability and an attractive, clean finish.

2. What is Robust Damp Seal Coating?

Robust Damp Seal Coating is a high-performance waterproofing coating designed to block dampness, resist efflorescence, and stop seepage from both interior and exterior walls. It forms a flexible, breathable membrane over the surface that prevents water penetration while allowing trapped moisture vapor to escape — ensuring the surface stays dry and intact.

It can be used on cement plaster, concrete, brick masonry, and other absorbent substrates. When applied correctly, it provides an excellent barrier against damp patches, fungus, and peeling paint, making it one of the most effective damp-proof coatings available today.

3. Composition and Technical Overview

Robust Damp Seal Coating is formulated using acrylic polymer emulsion, fine fillers, additives, and anti-fungal agents that enhance adhesion, flexibility, and UV resistance.

Technical Features:

-

Type: Acrylic-based waterproof coating

-

Appearance: White viscous liquid (dries to a semi-gloss or matte finish)

-

Mixing Ratio: Single-component ready-to-use or two-part system (as required)

-

Density: 1.35 ± 0.05 g/cc

-

Coverage: 1–1.5 m²/kg per coat (depending on surface texture)

-

Drying Time: Touch dry in 30–45 minutes; recoatable after 4–6 hours

-

Full Cure: 72 hours

-

Application Tools: Brush, roller, or spray machine

4. Key Benefits of Robust Damp Seal Coating

1. Superior Waterproofing

Forms a dense film that effectively blocks water penetration through walls, ceilings, and foundations.

2. Excellent Adhesion

Adheres strongly to cement, plaster, brick, and concrete, ensuring lasting protection.

3. Breathable Membrane

Allows moisture vapor to escape while preventing liquid water from entering — avoiding paint blistering.

4. UV & Weather Resistance

Maintains color stability and protection even under harsh sunlight and heavy rain.

5. Anti-Fungal & Algae Resistant

Contains bio-resistant additives that prevent black patches, algae, and fungus growth.

6. Crack Bridging Ability

Flexible coating bridges hairline cracks and prevents surface deterioration.

7. Cost-Effective

Long-lasting durability means fewer maintenance cycles and lower long-term costs.

5. Areas of Application

Robust Damp Seal Coating is suitable for interior and exterior waterproofing across multiple surfaces:

-

Interior walls affected by rising dampness

-

Exterior walls exposed to rain and moisture

-

Basements and foundations where water ingress is common

-

Roof slabs and parapet walls

-

Bathrooms and kitchens (above tile height or non-immersed areas)

-

Water tanks and sumps (outer surfaces)

-

Cement plastered surfaces before paint application

6. Surface Preparation – The Foundation of Success

Before applying Robust Damp Seal Coating, ensure the substrate is properly prepared.

Step 1: Clean the surface thoroughly — remove dust, dirt, oil, and loose particles.

Step 2: Repair cracks using Robust Crack Filler or polymer-modified mortar.

Step 3: Ensure the surface is slightly damp but not wet before coating.

Step 4: For best results, apply Robust Primer if the substrate is too porous.

A well-prepared surface ensures maximum adhesion and long-term waterproofing performance.

7. Application Instructions

Step 1: Mixing

If supplied as a single component, stir thoroughly before use. For two-part systems, mix base and liquid components in the recommended ratio until a uniform consistency is achieved.

Step 2: Application

-

Apply the first coat using a brush, roller, or spray.

-

Allow it to dry for 4–6 hours.

-

Apply the second coat perpendicular to the first for uniform coverage.

-

Maintain consistent film thickness across the surface.

Step 3: Drying & Curing

Allow the coating to dry completely for 48–72 hours before exposure to water. Avoid applying under direct sunlight or heavy rain conditions.

8. Coverage and Consumption

Coverage depends on substrate porosity, surface texture, and application thickness.

| Application Area | Average Coverage | Recommended Coats |

|---|---|---|

| Interior Walls | 1.5 m²/kg/coat | 2 |

| Exterior Walls | 1.2 m²/kg/coat | 2–3 |

| Roofs / Parapets | 1.0 m²/kg/coat | 3 |

9. Storage and Shelf Life

-

Store in a cool, dry place away from direct sunlight.

-

Keep container tightly closed when not in use.

-

Shelf Life: 12 months in unopened condition.

10. Safety Precautions

-

Avoid contact with skin and eyes; use gloves and goggles.

-

Ensure adequate ventilation during application.

-

In case of skin contact, wash immediately with soap and water.

-

Do not mix with cement or other chemicals unless recommended.

11. Comparison: Robust Damp Seal Coating vs Other Coatings

| Feature | Robust Damp Seal | Bitumen Coating | PU Coating |

|---|---|---|---|

| Base Material | Acrylic Polymer | Bituminous | Polyurethane |

| Breathability | ✅ High | ❌ Low | ✅ Medium |

| UV Resistance | ✅ Excellent | ❌ Poor | ✅ Good |

| Aesthetic Finish | ✅ Paintable | ❌ Black | ✅ Glossy |

| Application Ease | ✅ Simple | ⚠️ Messy | ⚠️ Skill-Dependent |

| Odor / VOC | ✅ Low | ❌ Strong | ⚠️ Moderate |

| Recoating | ✅ Easy | ❌ Difficult | ⚠️ Moderate |

Conclusion:

Robust Damp Seal Coating offers the perfect balance of breathability, flexibility, and UV stability, outperforming conventional bitumen coatings while being more economical than PU-based systems.

12. Advantages for Builders and Homeowners

-

Enhances paint durability and aesthetic appeal

-

Reduces maintenance costs

-

Prevents mold and mildew growth

-

Extends structure lifespan

-

Compatible with most decorative paints

-

Environmentally friendly and low VOC

Whether you are a contractor, engineer, or homeowner, choosing Robust Damp Seal Coating means investing in a durable and reliable waterproofing solution backed by the Robust Construction Chemicals reputation for excellence.

13. Real-World Applications & Case Studies

Residential Buildings:

Used on interior damp walls before repainting, eliminating moisture stains and efflorescence.

Commercial Projects:

Ideal for facade waterproofing and protection of exposed plaster surfaces in malls, schools, and offices.

Industrial Sheds:

Prevents corrosion and damp-induced surface deterioration.

Infrastructure Works:

Applied on retaining walls, basements, and podium slabs for moisture resistance.

14. Maintenance and Recoating

Routine inspection every 3–5 years ensures coating integrity. If minor wear or discoloration appears, a single recoating with Robust Damp Seal Coating restores full protection without removing the existing layer.

15. Environmental Benefits

Robust Damp Seal Coating is eco-friendly, solvent-free, and non-toxic. It contains low VOCs, making it safe for interior use and compliant with modern green building standards.

16. Frequently Asked Questions (FAQs)

Q1: Can it be painted over?

Yes, once fully cured, it can be painted with emulsion or acrylic paints.

Q2: Is it suitable for underground areas?

Yes, it provides excellent damp-proof protection for basements and retaining walls.

Q3: How long does it last?

With proper application, the coating lasts 8–10 years depending on exposure conditions.

Q4: Can it be applied over old paint?

No. Remove loose paint and prepare a clean, stable surface before application.

Q5: Can it resist salt efflorescence?

Yes, the formulation helps prevent white salt deposits from emerging on the surface.

17. Conclusion

Robust Damp Seal Coating stands as a comprehensive waterproofing solution that blends science, performance, and reliability. Its advanced acrylic polymer technology ensures deep protection against dampness, efflorescence, and wall seepage — all while maintaining breathability and aesthetics.

When used as part of a Robust Construction Chemicals waterproofing system, it enhances structural life, ensures lasting beauty, and delivers peace of mind for years.

Additional information

| Weight | 1 kg |

|---|

Related products

-

Sale!

Robust geotextile roll

₨ 5,500Original price was: ₨ 5,500.₨ 5,000Current price is: ₨ 5,000. Add to cart -

Sale!

Robust hot bitumen

₨ 55,000Original price was: ₨ 55,000.₨ 52,000Current price is: ₨ 52,000. Add to cart -

Sale!

Robust Tile Bond

₨ 750Original price was: ₨ 750.₨ 700Current price is: ₨ 700. Add to cart -

Robust backer rod

Read more