Best PVC Water Stopper in Pakistan | Robust Construction Chemicals

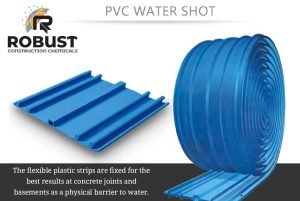

In the field of modern waterproofing and concrete protection, the PVC Water Stopper plays a crucial role in ensuring watertight integrity across various civil engineering structures. As one of the best PVC water stoppers in Pakistan, Robust Construction Chemicals has set new standards of durability, performance, and quality in waterproofing solutions. Designed for long-term resistance against hydrostatic pressure, chemical attack, and structural movement, our PVC water stoppers provide reliable protection to construction joints, expansion joints, and contraction joints in water-retaining and water-excluding structures. Whether it’s a basement, tunnel, dam, water tank, or retaining wall, Robust PVC Water Stopper ensures a leak-free and secure concrete structure that stands the test of time.

PVC (Polyvinyl Chloride) is a high-performance, flexible, and durable material that has proven its excellence in construction waterproofing for decades. Our PVC Water Stopper acts as a continuous barrier within concrete joints to prevent water seepage and infiltration through cracks or gaps formed due to temperature changes or structural movement. This makes it one of the most essential waterproofing accessories used in modern civil engineering and infrastructure projects. With the growing need for sustainable and cost-effective waterproofing systems in Pakistan, Robust Construction Chemicals proudly offers premium-quality PVC water stoppers manufactured under strict quality standards to meet both local and international specifications.

Why Choose Robust PVC Water Stopper in Pakistan?

When it comes to choosing the best PVC water stopper in Pakistan, several factors such as durability, flexibility, tensile strength, and resistance to harsh environmental conditions play a major role. Robust Construction Chemicals offers a range of PVC water stoppers designed to provide superior performance under challenging construction and environmental conditions.

-

Superior Waterproofing Efficiency:

Our PVC water stopper ensures a watertight seal that prevents water ingress at construction and expansion joints. It provides long-lasting waterproofing protection to all kinds of concrete structures, including basements, swimming pools, tunnels, and water reservoirs. -

Flexible and Durable Design:

The high-quality PVC compound used in Robust water stoppers offers excellent flexibility, making it easy to install even in complex joint geometries. It can withstand structural movements and high pressure without cracking or tearing. -

Chemical and Corrosion Resistance:

Robust PVC water stoppers are resistant to a wide range of chemicals, salts, and alkalis found in soil or groundwater, ensuring long-term protection against corrosion and degradation. -

High Tensile Strength:

With superior tensile and tear strength, our water stoppers maintain their shape and functionality even under heavy loads or stress, ensuring reliability for decades. -

Multiple Profiles Available:

We manufacture PVC water stoppers in different shapes and sizes such as central bulb type, dumbbell type, flat ribbed type, and external type, each suited to specific construction requirements. -

Temperature and UV Resistance:

Robust PVC water stoppers are specially formulated to resist high temperatures and UV radiation, ensuring consistent performance even in harsh climatic conditions across Pakistan. -

Cost-Effective and Long-Lasting:

Investing in a high-quality PVC water stopper minimizes long-term maintenance costs, reduces leakage risk, and increases the lifespan of the entire structure.

Applications of PVC Water Stopper in Construction

PVC water stoppers are essential components for structures where water containment or exclusion is critical. At Robust Construction Chemicals, our products are used in:

-

Basements and Foundations: Prevent groundwater seepage and leakage in below-ground structures.

-

Water Tanks and Reservoirs: Maintain complete watertight integrity for potable or industrial water tanks.

-

Tunnels and Subways: Protect against underground water infiltration and ensure dry internal surfaces.

-

Retaining Walls: Prevent moisture intrusion that may damage the wall and adjacent areas.

-

Dams and Canals: Provide waterproof joints capable of handling high water pressure.

-

Sewage and Drainage Plants: Resist aggressive chemicals and constant water flow.

-

Swimming Pools: Maintain a leak-free pool structure, even under continuous water exposure.

-

Parking Decks and Podiums: Protect structural slabs and decks from rainwater seepage.

Types of PVC Water Stopper

Robust Construction Chemicals provides different types of PVC water stoppers for different site requirements:

-

Center Bulb Type:

Designed for expansion joints to absorb movement and maintain watertightness. The center bulb allows flexibility and stress absorption. -

Dumbbell Type:

Ideal for construction joints where limited movement is expected. Provides excellent sealing against water leakage. -

Flat Rib Type:

Commonly used in horizontal and vertical construction joints. Its ribbed surface ensures superior bonding with concrete. -

External Type Water Stopper:

Placed on the external face of the concrete member, typically in retaining walls and basements where internal placement is not possible. -

Kicker Type or Surface Mounted:

Used where joint placement space is limited or during repairs where conventional embedding isn’t possible.

Each type is engineered to meet specific site challenges and provide maximum waterproofing efficiency under different stress conditions.

Installation Guidelines for PVC Water Stopper

Proper installation is crucial for the performance of a PVC water stopper. Below are professional installation instructions recommended by Robust Construction Chemicals:

-

Site Preparation:

Clean the joint area thoroughly and ensure no dirt, oil, or debris remains before placing the water stopper. -

Positioning:

Position the water stopper accurately in the formwork ensuring that half of it remains embedded in the first concrete pour and the other half in the second pour. -

Fixing:

Use nails, clips, or wiring to hold the stopper in place during concrete pouring to prevent displacement. -

Joint Welding:

Overlaps and intersections should be heat-welded using an electrical heating blade or splicing jig to ensure a watertight seal. -

Pouring Concrete:

Pour the concrete carefully around the stopper to avoid movement and ensure complete encapsulation without voids. -

Inspection:

Check for uniform alignment and any signs of bending, twisting, or displacement before the concrete sets.

Advantages of Using Robust PVC Water Stopper

-

Excellent long-term waterproofing solution.

-

Prevents water leakage through joints and cracks.

-

Enhances the durability and lifespan of structures.

-

Easy to install and maintain.

-

Cost-effective solution compared to other joint sealing methods.

-

Flexible under temperature changes and pressure.

-

Resistant to chemicals and weathering.

-

Suitable for both fresh and saltwater exposure.

-

Available in various sizes and thicknesses.

-

Designed and tested for Pakistani construction standards.

Why Robust Construction Chemicals is Pakistan’s Leading Manufacturer

With years of expertise in construction chemicals and waterproofing solutions, Robust Construction Chemicals has earned a strong reputation for providing reliable, durable, and high-performance products across Pakistan. Our PVC water stoppers are manufactured using advanced polymer processing technology under strict quality control. We ensure every batch meets international standards such as ASTM and BS specifications. From Karachi to Lahore, Islamabad to Multan, our PVC water stoppers have been successfully installed in thousands of residential, commercial, and industrial projects.

Robust not only provides products but also offers complete technical support, on-site assistance, and guidance for proper installation and application. Our engineering team works closely with contractors and architects to recommend the right type and profile for every project. This makes Robust Construction Chemicals the most trusted name in PVC water stopper supply in Pakistan.

Sustainability and Long-Term Benefits

By using Robust PVC Water Stopper, contractors and builders contribute to sustainable construction. Our products are made from eco-friendly, recyclable materials that reduce waste and environmental impact. The long service life and zero-maintenance performance ensure reduced lifecycle costs and improved structure durability. Whether you are working on new construction or retrofitting an existing structure, our PVC water stoppers guarantee maximum waterproofing efficiency with minimal environmental footprint.

Conclusion

When you invest in Robust PVC Water Stopper, you invest in long-lasting protection, performance, and peace of mind. Our product stands as the best PVC water stopper in Pakistan, providing unmatched reliability, superior flexibility, and outstanding resistance against leakage, pressure, and weathering. From basements and water tanks to dams and tunnels, Robust ensures every joint stays sealed, every structure stays dry, and every project meets the highest waterproofing standards.

Technical Properties of Robust PVC Water Stopper

A high-quality PVC Water Stopper must possess exceptional physical, mechanical, and chemical properties to perform effectively in all types of concrete structures. At Robust Construction Chemicals, we engineer our products to deliver superior performance under the toughest construction conditions found in Pakistan.

Key Technical Specifications:

-

Material Composition:

Premium-grade Polyvinyl Chloride (PVC), free from recycled content or plasticizers that could degrade performance. -

Hardness (Shore A):

75 ± 5 — providing a perfect balance between flexibility and toughness. -

Tensile Strength:

Greater than 12 N/mm², ensuring long-lasting durability even under pressure. -

Elongation at Break:

Above 300%, allowing it to stretch and absorb structural movement without losing its sealing properties. -

Specific Gravity:

1.35 ± 0.05, providing strong bonding and ideal embedment within concrete joints. -

Water Absorption:

Less than 0.2%, ensuring zero permeability even under prolonged water exposure. -

Service Temperature Range:

-25°C to +70°C — suitable for Pakistan’s varying climatic conditions, from the cold of Murree to the heat of Karachi. -

Chemical Resistance:

Resistant to alkalis, mild acids, salts, chlorides, and sulfates commonly found in groundwater and construction environments. -

Compliance Standards:

-

ASTM D638

-

BS 2571

-

IS 12200:2001

-

ACI 504R Guidelines for Waterstops

-

Each batch of Robust PVC Water Stopper is tested in our advanced laboratory to ensure consistency, strength, and waterproofing integrity.

How PVC Water Stopper Works

The working principle of a PVC Water Stopper is simple yet highly effective. It acts as a physical barrier inside concrete joints, blocking water passage even under extreme hydrostatic pressure. When concrete expands, contracts, or experiences movement due to temperature changes or settlement, the PVC Water Stopper stretches accordingly, maintaining its watertight seal.

In construction joints, it ensures that cold joints do not become leakage points. In expansion joints, the central bulb or hollow profile of the stopper absorbs movement and vibration while maintaining the seal. This dual performance makes it essential in all water-retaining and water-excluding structures such as underground basements, lift pits, swimming pools, water tanks, and treatment plants.

Detailed Installation Guidelines

For ensuring long-term waterproofing performance, it’s critical to install the PVC Water Stopper accurately. Below are the step-by-step professional instructions recommended by Robust Construction Chemicals’ technical team:

1. Joint Design:

Before starting installation, ensure the correct type and size of water stopper is selected according to the joint type (construction, expansion, or contraction). Central bulb types are ideal for expansion joints, while dumbbell types are suitable for construction joints.

2. Cutting and Welding:

Cut the water stopper using a sharp knife or fine saw. For joining ends or making cross, L, or T joints, use electric heating elements or a splicing jig to heat-weld both surfaces. Always perform a sample weld and check for continuity to ensure no leakage point exists.

3. Fixing Before Pouring:

-

Place half of the water stopper within the first pour of concrete and leave the remaining half for the second pour.

-

Secure the water stopper with steel wires, clamps, or specially designed fixing eyes to prevent displacement during concreting.

-

Make sure the stopper is centrally aligned with the joint line.

4. Concrete Pouring:

During concreting, ensure proper vibration around the water stopper to remove air pockets. Avoid over-vibration, as it may displace the stopper. Allow concrete to flow uniformly around the ribs for maximum bonding.

5. Post-Installation Inspection:

Inspect all welded joints and embedded portions. There should be no visible cracks, air voids, or bends. Any minor misalignment should be corrected before the final concrete pour.

Maintenance Guidelines for Long-Term Performance

While PVC Water Stoppers are virtually maintenance-free, periodic inspection and preventive measures can enhance performance and lifespan:

-

Routine Checks:

Inspect exposed or accessible joints once a year to ensure no damage has occurred due to structural movement or external force. -

Minor Repairs:

In case of localized leakage, inject waterproofing grout or apply Robust PU Sealant to fill the micro-crack near the joint. -

Clean Drainage Systems:

Keep surrounding drains, outlets, and sump pits clear of blockage to minimize hydrostatic pressure buildup on joints. -

Avoid Chemical Contamination:

Where industrial effluents are present, ensure chemical-resistant grades of PVC water stoppers are used. -

Rehabilitation Projects:

For old concrete structures showing leakage, external PVC strips or injection systems can be installed alongside existing stoppers for enhanced waterproofing.

Advantages of PVC Water Stopper Over Other Materials

Although several materials like rubber and metal strips are used for waterproofing joints, PVC Water Stopper has become the most preferred option due to its superior performance and cost-effectiveness.

| Feature | PVC Water Stopper | Rubber Water Stopper | Metal Water Stopper |

|---|---|---|---|

| Flexibility | Excellent | Moderate | Poor |

| Chemical Resistance | High | Medium | Low |

| Corrosion Resistance | 100% | High | Poor |

| Installation | Easy | Difficult | Very Difficult |

| Cost | Economical | Moderate | Expensive |

| Longevity | 20+ years | 10–15 years | <10 years |

As shown, PVC water stoppers outperform alternative materials in almost every category, making them the smartest and most reliable waterproofing choice for modern construction.

Projects Using Robust PVC Water Stopper in Pakistan

Robust Construction Chemicals has successfully supplied PVC Water Stoppers to hundreds of prestigious projects across Pakistan. A few notable ones include:

-

Lahore Metro and Orange Line Stations

-

Bahria Town Underground Parking Structures

-

Water Treatment Plants in Islamabad

-

Karachi Industrial Zones and Warehouses

-

Multan and Faisalabad Textile Industries Basements

-

Hydroelectric Dams and Spillways

These projects stand as proof of Robust’s commitment to quality and reliability, where our products have consistently delivered long-term waterproofing success in complex and large-scale structures.

Tips for Contractors and Engineers

For achieving the best results from PVC Water Stopper installation, Robust recommends the following professional tips:

-

Use approved welding equipment to join stopper ends.

-

Never use nails or screws directly through the water stopper—use eyelets or clamps.

-

Always maintain a minimum embedment of 50% within the concrete section.

-

Avoid exposure to direct sunlight for long durations before installation.

-

Choose the correct profile width (150mm, 230mm, 320mm, etc.) based on joint width and water pressure.

-

Always perform a trial installation on-site before mass use.

Storage and Handling Instructions

-

Store rolls horizontally on flat surfaces in a cool, shaded area.

-

Avoid stacking heavy materials over the rolls.

-

Protect from sharp objects that may cause puncture or deformation.

-

Shelf life: 12–18 months in original packaging when stored under proper conditions.

-

Clean with mild detergent and water if dust accumulates before installation.

Robust Quality Assurance and Testing

Each Robust PVC Water Stopper undergoes rigorous testing for tensile strength, elongation, chemical resistance, and weldability. Our laboratory uses international testing methods including ASTM D638, ASTM D570, and IS 12200.

Additionally, we provide Third-Party Test Certificates (TPCs) upon request to meet consultant or client specifications. Quality assurance is part of every production batch to ensure that every water stopper leaving our plant is 100% reliable and defect-free.

Why Pakistan Chooses Robust

Pakistan’s construction industry is evolving rapidly, with new technologies demanding more efficient and sustainable waterproofing solutions. Contractors, consultants, and developers across the country trust Robust Construction Chemicals because we offer:

-

Decades of waterproofing experience.

-

Nationwide availability and supply.

-

Technical on-site support and installation training.

-

Custom sizes, thicknesses, and profiles upon request.

-

Consistent quality that meets global standards.

-

Competitive pricing with quick delivery.

With an unwavering focus on quality, innovation, and trust, Robust continues to lead the construction chemical industry in Pakistan, helping safeguard concrete structures from the most common enemy — water intrusion.

Conclusion

In every construction project — whether it’s a high-rise basement, dam, tunnel, or water tank — water leakage poses a serious threat to long-term durability. The only solution lies in choosing the right waterproofing material, and that’s where Robust PVC Water Stopper stands out as the best in Pakistan.

Engineered with advanced technology, tested for the toughest conditions, and trusted by engineers and builders nationwide, Robust PVC Water Stopper guarantees watertight performance, easy installation, and long service life. It’s not just a product — it’s your project’s assurance of protection against water seepage for years to come.

Choose Robust Construction Chemicals, Pakistan’s most trusted name in waterproofing innovation — where strength meets reliability.