Robust EPS Thermacol Sheet | Best Heatproof & Thermal Insulation Solution for Roofs, Walls & Floors Worldwide

Introduction: Importance of Thermal Insulation Globally

Energy efficiency, thermal comfort, and sustainability have become critical in modern construction worldwide. Buildings across climates—from the scorching heat of the Middle East to the humid tropics of South Asia and the cold winters of Europe—require innovative insulation solutions to maintain comfortable indoor temperatures while reducing energy consumption. Poor insulation leads to excessive energy bills, uncomfortable living or working conditions, and faster structural degradation due to temperature fluctuations and moisture infiltration.

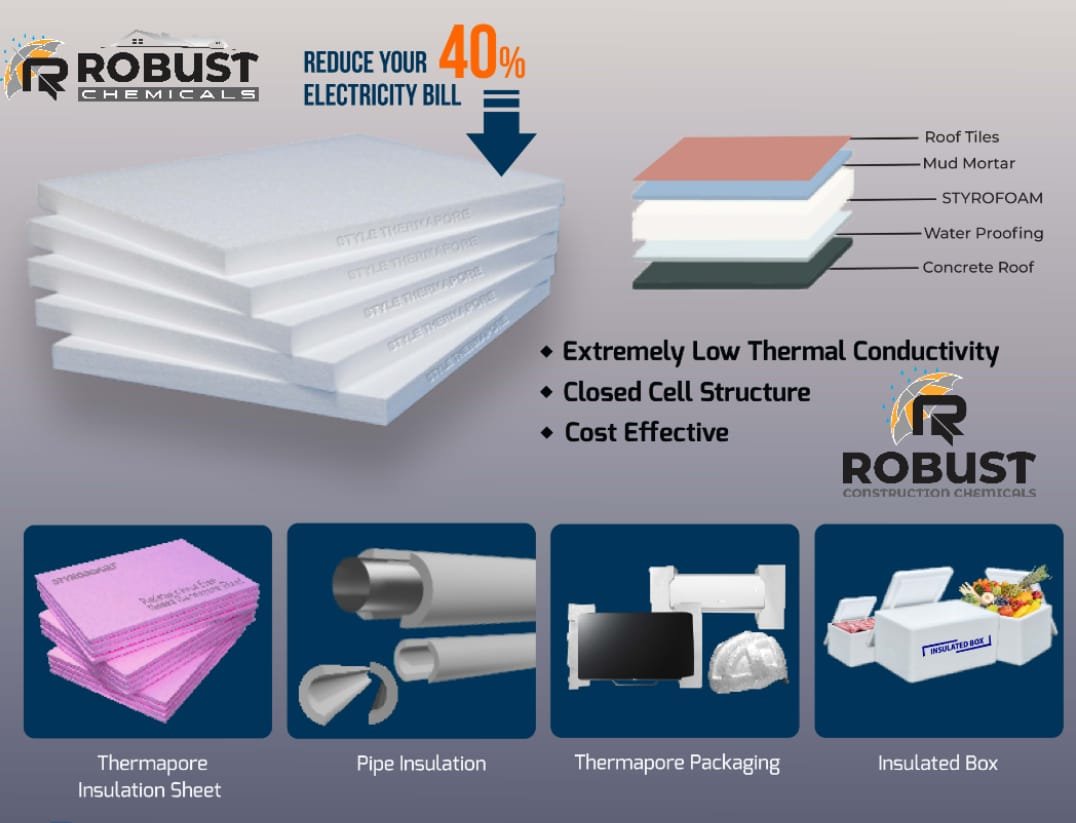

Robust EPS Thermacol Sheet is a premium heatproof and thermal insulation solution designed for roofs, walls, and floors globally. Its lightweight structure, superior thermal resistance, and moisture-proof properties make it ideal for residential, commercial, and industrial applications. With the rising global demand for sustainable construction materials, EPS Thermacol Sheets offer an eco-friendly, cost-effective, and highly efficient insulation solution.

Internal Link: Learn more about our insulation solutions at Robust Construction Chemicals

Facebook Link: Follow us on Facebook

What is EPS Thermacol Sheet?

EPS (Expanded Polystyrene) Thermacol Sheet is a lightweight, rigid, and highly insulating foam material. Manufactured from high-quality polystyrene beads, EPS sheets are expanded and molded into panels that provide excellent thermal insulation. Its microcellular structure traps air, which reduces heat transfer through conduction, convection, and radiation, making it a highly energy-efficient material.

Key Features of EPS Thermacol Sheet:

-

High Thermal Resistance: Maintains indoor temperatures by reducing heat gain in summer and heat loss in winter.

-

Lightweight: Easy to handle and install without requiring extra structural support.

-

Moisture Resistant: Prevents water absorption, reducing the risk of mold and structural damage.

-

Durable: Long-lasting insulation that requires minimal maintenance.

-

Eco-Friendly: Non-toxic and recyclable, supporting sustainable construction practices.

-

Versatile: Suitable for residential, commercial, and industrial buildings globally.

External Link: Learn more about EPS insulation at Wikipedia – Expanded Polystyrene

Key Advantages of Robust EPS Thermacol Sheet

1. Energy Efficiency

EPS sheets are known for their excellent thermal insulation, which keeps buildings cooler in summer and warmer in winter. Reduced reliance on air conditioning and heating systems lowers electricity bills and supports green building practices.

2. Cost-Effectiveness

EPS Thermacol Sheets provide long-term savings by reducing energy consumption and maintenance costs. Their durability ensures minimal replacement, making them a cost-effective solution for global construction projects.

3. Easy Installation

EPS panels are lightweight and easy to cut and fit, reducing labor costs and installation time. They are compatible with concrete, metal, wood, and tiled surfaces.

4. Moisture & Water Resistance

EPS sheets are highly resistant to water absorption, preventing dampness, mold growth, and structural damage.

5. Soundproofing

The air pockets in EPS sheets act as sound barriers, reducing external noise and improving indoor acoustic comfort.

6. Sustainable & Eco-Friendly

EPS is recyclable and non-toxic, making it suitable for environmentally conscious projects. Its energy-saving properties also contribute to a lower carbon footprint.

Applications of EPS Thermacol Sheet

-

Roof Insulation:

Reduces indoor heat gain and improves comfort. Compatible with residential, commercial, and industrial rooftops. -

Wall Insulation:

Prevents heat transfer through walls, maintaining consistent indoor temperatures. Helps reduce HVAC energy consumption. -

Floor Insulation:

Protects against heat and cold from the ground, ensuring thermal comfort for occupants. -

Industrial Buildings:

Warehouses, factories, and cold storage facilities benefit from temperature control and energy savings. -

Residential & Commercial Projects:

Apartments, villas, offices, and shopping malls benefit from energy efficiency, reduced operational costs, and improved comfort.

Internal Link: Complementary product: Robust Foil Aluminium Membrane Sheet

Scientific Insights: How EPS Works

EPS sheets trap millions of tiny air pockets in their structure. These air pockets serve as a natural thermal barrier, significantly reducing heat transfer. Optional reflective coatings can enhance heat deflection from roofs and walls, further improving energy efficiency.

Seasonal Performance:

-

Summer: Prevents excessive heat penetration into interiors, keeping spaces cooler.

-

Winter: Retains indoor warmth, reducing energy required for heating.

Moisture Resistance: EPS sheets absorb minimal water, maintaining their insulation performance even in high-humidity regions.

Sound Insulation: EPS reduces external noise pollution, making it ideal for urban residential or commercial projects.

Step-by-Step Installation Guide

-

Surface Preparation:

Clean the installation surface, remove dust, debris, or moisture, and repair cracks. -

Cutting and Shaping:

Use a sharp knife or hot-wire cutter to trim sheets to the required size for tight fitting. -

Placement:

Lay sheets flat on roofs, walls, or floors. Ensure edges and joints are tightly aligned. -

Fixing & Adhesion:

Use mechanical fasteners or construction adhesive to secure sheets. For exposed roofs, consider a protective layer like tiles, screed, or foil membranes. -

Sealing Joints:

Seal gaps with tape or foam to prevent thermal leakage. -

Optional Protective Layer:

Add tiles, screed, or gravel for additional durability in high-traffic areas.

Case Studies: EPS Thermacol Sheet Worldwide

1. Lahore Residential Rooftop

Problem: Excessive heat causing discomfort.

Solution: EPS Thermacol sheet installed with reflective membrane.

Result: Reduced indoor temperature by 20%, energy-efficient cooling.

2. Karachi Industrial Cold Storage

Problem: Maintaining low temperatures for sensitive goods.

Solution: EPS sheets applied on walls and ceiling.

Result: Energy-efficient insulation, reduced cooling costs.

3. Islamabad Commercial High-Rise

Problem: Noise and heat in office floors.

Solution: EPS sheet insulation combined with foil aluminium membrane.

Result: Comfortable indoor environment, reduced AC usage.

4. Faisalabad Textile Factory

Problem: Heat affecting machinery performance.

Solution: EPS sheets on roof and walls.

Result: Cooler workspace, improved productivity, and energy savings.

Internal Link: Learn about complementary insulation solutions at Robust Construction Chemicals

Maintenance & Longevity

-

Inspect panels annually for damage or cracks.

-

Keep surfaces clean from debris, dust, and leaves.

-

Replace damaged sheets promptly.

-

Combine with waterproofing membranes for extreme climate protection.

Environmental & Energy Benefits

-

Reduces electricity consumption for AC and heating.

-

Recyclable, non-toxic material supports sustainable construction.

-

Reduces urban noise pollution.

-

Contributes to LEED and green building certifications.

Energy-Saving Example: Installing EPS sheets in a 3-story building in Lahore reduced AC load by 25–30%, saving significant electricity costs annually.

Extended FAQs

Q1: Can EPS sheets be installed on old buildings?

A1: Yes, with proper surface preparation and crack repair.

Q2: Are EPS sheets suitable for extreme heat or cold conditions?

A2: Yes, EPS provides excellent thermal insulation across diverse climates.

Q3: Can EPS sheets be layered for higher insulation?

A3: Yes, layering improves R-value and provides superior heatproofing.

Q4: Are EPS sheets safe for potable water tanks?

A4: Yes, non-toxic and safe for potable water storage.

Q5: Can EPS sheets be used in industrial, high-traffic areas?

A5: Yes, with a protective top layer such as screed, tiles, or foil membrane.

Conclusion

Robust EPS Thermacol Sheet is the ultimate solution for heatproofing and thermal insulation worldwide. It is ideal for:

-

Residential, commercial, and industrial buildings

-

Roofs, walls, floors, and cold storage units

-

Sustainable, energy-efficient construction projects

Internal Link: Explore more products at Robust Construction Chemicals

Facebook Link: Follow us on Facebook

Advanced Technical Insights of Robust EPS Thermacol Sheet

Composition and Structure

EPS (Expanded Polystyrene) Thermacol Sheets are composed of high-grade polystyrene beads, which are expanded using heat and steam to form rigid panels. Each panel contains millions of air pockets that provide excellent thermal resistance. This microcellular structure reduces heat transfer via conduction, convection, and radiation, making it a superior insulation material.

Key Components:

-

Polystyrene Beads: Provide core insulation and lightweight structure.

-

Optional Coatings: Reflective, fire-retardant, or UV-protective layers improve performance and durability.

-

Adhesion Layer: Ensures secure installation on walls, floors, and roofs.

External Link: Learn about EPS properties at ScienceDirect – Expanded Polystyrene Applications

Thermal Performance & R-Value

EPS Thermacol Sheets are evaluated based on their R-value, which measures thermal resistance. Higher R-values indicate better insulation.

-

Standard EPS Sheets: R-value ~ 3.5–4.0 per inch thickness.

-

High-Density EPS: R-value ~ 4.5–5.0 per inch, suitable for extreme climates.

Seasonal Performance Globally:

-

Summer: EPS sheets minimize indoor heat gain, reducing the cooling load on air conditioning systems.

-

Winter: Retains warmth inside buildings, reducing the need for heating.

Internal Link: Complementary product: Robust Foil Aluminium Membrane Sheet

Fire Safety & Regulatory Compliance

EPS Thermacol Sheets can be enhanced with fire-retardant coatings to comply with international building safety codes. They are classified based on flame spread and smoke development:

-

Class A (ASTM E84): Flame-resistant, suitable for commercial and residential applications.

-

Class B: Moderate flame spread, mainly used in industrial and storage facilities.

EPS sheets installed in combination with fire-rated membranes improve building safety in urban and industrial environments.

External Link: ASTM Fire Safety Standards: ASTM E84 Standard

Extended Applications Worldwide

1. Residential Buildings

EPS sheets are widely used in villas, apartments, and high-rise residences for:

-

Roof terraces to prevent heat gain

-

Wall insulation to maintain indoor temperatures

-

Floor insulation for thermal comfort and reduced heating costs

2. Commercial Buildings

Office towers, shopping malls, hotels, and hospitals benefit from:

-

Enhanced energy efficiency, reducing operational costs

-

Soundproofing for urban environments

-

Moisture resistance for indoor comfort and structural integrity

3. Industrial Facilities

EPS sheets are suitable for factories, warehouses, and cold storage facilities:

-

Insulates large floor and wall areas efficiently

-

Maintains temperature-sensitive materials and machinery

-

Reduces energy expenditure in climate-controlled industrial spaces

4. Infrastructure Projects

Used in bridges, tunnels, and public infrastructure:

-

Provides thermal protection to concrete structures

-

Reduces expansion and contraction stresses

-

Enhances long-term durability of concrete surfaces

Internal Link: Explore more industrial solutions at Robust Construction Chemicals

Comparative Analysis: EPS vs Other Insulation Materials

| Feature | EPS Thermacol Sheet | XPS Sheet | PU Foam | Mineral Wool |

|---|---|---|---|---|

| Thermal Insulation | High | High | Medium-High | Medium |

| Weight | Very Light | Heavy | Medium | Medium |

| Moisture Resistance | Excellent | Excellent | Moderate | Poor |

| Sound Insulation | Good | Medium | Medium | High |

| Ease of Installation | Very Easy | Medium | Medium | Medium |

| Fire Safety | Class-rated | Class-rated | Flame-resistant | Flame-resistant |

| Cost | Cost-effective | Expensive | Moderate | Moderate |

| Durability | 10–15+ years | 15–20 years | 10–12 years | 8–10 years |

Why EPS Thermacol is Preferred Globally:

-

Lightweight reduces structural load.

-

Superior thermal insulation lowers energy costs.

-

Excellent moisture resistance prevents mold and structural damage.

-

Cost-effective for large-scale residential and industrial projects.

External Link: EPS Benefits – Wikipedia – Expanded Polystyrene

Advanced Installation Techniques

Surface Preparation

-

Clean and level surface to remove dust, debris, oil, and loose materials

-

Repair cracks and uneven surfaces to ensure full contact with EPS sheets

Cutting & Shaping

-

Use hot-wire cutters or sharp knives for precise edges

-

Pre-measure panels to fit tightly in corners and around obstacles

Placement & Fixing

-

Lay sheets flat on the installation surface

-

Use adhesive or mechanical fasteners as required

-

For roofs or exposed areas, add protective screed, tiles, or foil membrane

Sealing & Protective Layer

-

Seal joints using adhesive tape or insulating foam

-

Optional top layers for high-traffic areas, UV exposure, or heavy loads

Extended Case Studies Worldwide

1. Dubai Residential High-Rise

Problem: Excessive rooftop heat due to desert climate.

Solution: EPS Thermacol Sheets installed under reflective membrane.

Result: Indoor temperature reduced by 30%, energy-efficient cooling, and lower AC bills.

2. Singapore Commercial Complex

Problem: Noise pollution and heat gain in office spaces.

Solution: EPS sheets combined with soundproofing membranes.

Result: Quieter, cooler environment; improved employee comfort and productivity.

3. Germany Cold Storage Warehouse

Problem: Maintaining sub-zero temperatures for perishable goods.

Solution: EPS sheets installed on walls and floors.

Result: Stable temperature, reduced energy consumption, and prolonged product life.

4. Australia Residential Villa

Problem: Extreme weather fluctuations affecting indoor comfort.

Solution: Roof and wall insulation using EPS Thermacol Sheets.

Result: Year-round thermal comfort, reduced HVAC usage, and long-term energy savings.

Internal Link: Learn more at Robust Construction Chemicals Projects

Environmental & Sustainability Benefits

-

Eco-Friendly Material: Non-toxic, recyclable, and safe for residential, commercial, and industrial buildings.

-

Energy Savings: Reduces electricity usage for air conditioning and heating.

-

Durable Material: Long-lasting, reducing the frequency of replacements and material waste.

-

Noise Reduction: Improves indoor acoustic comfort in urban projects.

-

Supports Green Certifications: Helps projects comply with LEED and other sustainability standards.

External Link: Green Building Standards – USGBC

Maintenance & Longevity

-

Annual inspection for damage, cracks, or punctures

-

Cleaning surfaces to remove dirt, moss, and debris

-

Replace damaged sheets promptly to maintain insulation efficiency

-

Combine with waterproofing solutions for extreme monsoon or humid climates

Extended FAQs

Q1: Can EPS sheets be installed on sloped roofs?

A1: Yes, with overlapping joints and adhesive, they work perfectly on sloped surfaces.

Q2: Are EPS sheets suitable for extreme climates?

A2: Yes, they provide excellent thermal insulation in both high-heat and cold regions.

Q3: Can EPS be layered for higher insulation?

A3: Layering improves R-value and provides additional heatproofing.

Q4: Are EPS sheets safe for potable water applications?

A4: Absolutely, EPS is non-toxic and safe for water tanks.

Q5: Can EPS sheets be used in industrial high-traffic areas?

A5: Yes, with protective layers like tiles or screed.

Q6: How long do EPS sheets last?

A6: With proper installation, 10–15 years or more.

Global SEO Keywords

Primary Keywords:

EPS Thermacol Sheet, Roof Insulation, Wall Insulation, Floor Insulation, Heatproof Sheet, Thermal Insulation, Energy Efficient Building, Industrial Insulation Sheet

Long-Tail Keywords:

Best EPS Thermacol Sheet Worldwide, Affordable EPS Sheet for Roofs, Premium EPS Sheet for Walls, Energy Efficient EPS Sheet for Industrial Buildings, High-Density Thermal Insulation Sheet

Internal Links:

External Links:

Advanced Energy Efficiency Insights for EPS Thermacol Sheets

EPS Thermacol Sheets are not just insulation panels—they are a complete energy management solution for modern construction. By reducing heat transfer, they significantly lower electricity consumption for cooling and heating systems globally.

How EPS Improves Building Energy Efficiency

-

Reduced Heat Gain in Summer: The microcellular structure of EPS prevents excessive rooftop and wall heat penetration. Buildings remain cooler, reducing dependency on air conditioners.

-

Retained Warmth in Winter: EPS prevents indoor heat loss, keeping interiors warm and decreasing heating energy consumption.

-

Lower Peak Energy Demand: By maintaining stable indoor temperatures, EPS reduces the stress on HVAC systems during peak load periods, which is especially important in tropical and temperate climates.

-

Integrated Sustainable Design: When combined with reflective membranes or green roofing, EPS enhances sustainable building performance, supporting LEED and BREEAM certifications.

Internal Link: Explore combined solutions with Robust Foil Aluminium Membrane Sheet

External Link: Learn more about energy efficiency in buildings at Energy.gov – Building Energy Efficiency

EPS Thermacol for Extreme Climates Worldwide

EPS is used in diverse climates—from scorching deserts to cold mountainous regions. Its adaptability makes it the preferred choice for architects and builders across continents.

Desert Environments

-

Challenge: High daytime temperatures and intense solar radiation.

-

Solution: EPS sheets reduce rooftop heat gain by 25–30%, keeping indoor spaces cooler.

-

Case Example: Villas in Dubai implemented EPS combined with reflective coatings, reducing AC load and operational costs.

Tropical Regions

-

Challenge: High humidity and frequent rainfall.

-

Solution: Moisture-resistant EPS prevents mold growth and maintains thermal efficiency.

-

Case Example: Singapore office towers achieved better indoor comfort with EPS combined with soundproofing membranes.

Cold Climates

-

Challenge: Harsh winters with heat loss through walls and floors.

-

Solution: EPS provides excellent thermal retention, reducing heating needs.

-

Case Example: Industrial facilities in Germany maintained sub-zero storage temperatures efficiently using high-density EPS panels.

Noise Reduction & Acoustic Benefits

EPS sheets also offer significant soundproofing capabilities, especially in urban and industrial areas. The air pockets inside EPS panels absorb and dampen noise, providing quieter indoor environments.

-

Residential Applications: Reduces street noise in apartments and villas.

-

Commercial Applications: Improves acoustic comfort in offices, shopping malls, and conference halls.

-

Industrial Applications: Minimizes operational noise from machinery, protecting workers and sensitive equipment.

Internal Link: Complementary product: Robust Water Stopper

Extended Installation Techniques for Maximum Performance

Multi-Layer Insulation

-

Purpose: In areas with extreme heat or cold, installing multiple layers of EPS sheets enhances thermal resistance.

-

Method: Place the first layer, seal edges with insulating tape or foam, then apply additional layers with staggered joints.

Combined Insulation Solutions

-

EPS + Foil Aluminium Membrane: Provides dual benefits of thermal reflection and moisture resistance.

-

EPS + Waterproofing Chemicals: Ensures building envelopes are heatproof and leak-proof simultaneously.

Structural Considerations

-

Lightweight Design: EPS sheets reduce load on structural beams and slabs.

-

Compatibility: Can be installed on concrete, metal, or wooden structures without structural reinforcement.

-

Cut-to-Size Panels: Easily trimmed for customized applications, corners, and irregular surfaces.

Global Standards & Certifications

EPS Thermacol Sheets comply with international standards for insulation and safety:

-

ASTM C578: Standard specification for rigid cellular polystyrene thermal insulation.

-

ISO 9001: Quality management system ensuring consistency in production and performance.

-

LEED & BREEAM Compliance: EPS contributes to sustainable, energy-efficient construction projects worldwide.

-

Fire Safety: EPS panels are Class A rated with fire-retardant coatings, suitable for commercial and industrial applications.

External Link: Read about ISO and ASTM standards for insulation materials at ASTM International

Extended Case Studies & Global Applications

1. UAE Residential Villas

-

Problem: Intense rooftop heat and high electricity bills.

-

Solution: EPS sheets with reflective coatings.

-

Result: Reduced AC consumption by 28–30% and maintained comfortable indoor temperature.

2. India Urban Apartment Complex

-

Problem: Noise pollution and indoor heat gain.

-

Solution: EPS sheets combined with wall membranes.

-

Result: Lowered indoor temperatures and significantly reduced external noise.

3. European Cold Storage Facility

-

Problem: Maintaining consistent low temperatures.

-

Solution: High-density EPS panels on walls and floors.

-

Result: Stable temperature, energy-efficient cooling, and extended shelf life for perishable goods.

4. Australian Residential Homes

-

Problem: Heat fluctuations in urban homes.

-

Solution: Roof and wall EPS insulation.

-

Result: Reduced HVAC usage, lower electricity bills, and year-round comfort.

Environmental & Sustainability Highlights

EPS Thermacol Sheets are eco-friendly and promote sustainable construction:

-

Non-Toxic: Safe for human contact and potable water applications.

-

Recyclable: Reduces landfill waste when replaced or upgraded.

-

Energy Saving: Lowers operational energy needs for heating and cooling.

-

Noise Reduction: Minimizes urban noise pollution.

-

Longevity: Durable design reduces replacement frequency and material waste.

Internal Link: Explore sustainable building solutions at Robust Construction Chemicals

External Link: Green Building Certifications – USGBC LEED

Extended FAQs

Q1: Can EPS sheets be used on sloped and flat roofs?

A1: Yes, with proper overlapping and sealing, EPS works effectively on all roof types.

Q2: Are EPS sheets effective in humid and rainy climates?

A2: Absolutely. Moisture-resistant EPS prevents dampness, mold, and degradation.

Q3: Can EPS be used with existing insulation layers?

A3: Yes, EPS can be installed over or under other insulation systems for enhanced performance.

Q4: How long do EPS Thermacol Sheets last?

A4: With proper installation and maintenance, 10–15+ years of effective performance.

Q5: Are EPS sheets safe for drinking water storage applications?

A5: Yes, non-toxic EPS is suitable for water tanks and safe for potable water.