High-Performance Self-Leveling Epoxy Flooring | Smooth, Durable & Long-Lasting Floors –

Self-leveling epoxy flooring has become the top choice for homeowners, commercial property managers, and industrial builders in Pakistan. Known for its smooth, seamless, and highly durable surface, self-leveling epoxy provides long-lasting protection against wear, moisture, chemicals, and mechanical stress. Unlike traditional floor coatings, epoxy flooring creates a continuous surface with superior adhesion and minimal maintenance requirements. Whether used in homes, offices, factories, or warehouses, this type of flooring ensures both aesthetic appeal and structural resilience.

Internal links for related topics:

/industrial-flooring/

/residential-floor-coating/

/epoxy-floor-installation-guide/

What is Self-Leveling Epoxy Flooring?

Self-leveling epoxy flooring is a liquid polymer coating that spreads evenly across floors, filling cracks and creating a flat, smooth finish. It is typically a two-component system, combining epoxy resin with a hardener to initiate a chemical reaction that results in a tough, high-gloss surface. Unlike conventional paints or tiles, self-leveling epoxy bonds seamlessly to concrete, ensuring durable and uniform coverage.

External reference:

https://www.epoxyflooring.org/self-leveling-epoxy/

This flooring solution is suitable for both new constructions and renovation projects, as it can be applied directly over existing concrete surfaces, provided they are properly prepared.

Key Features and Benefits

1. Smooth and Seamless Finish

Self-leveling epoxy spreads uniformly across floors, creating a smooth, continuous surface without grout lines or joints. This not only enhances aesthetics but also prevents dirt and bacteria accumulation, making it ideal for hospitals, laboratories, and food processing areas.

2. High Durability

Epoxy floors are resistant to heavy foot traffic, mechanical impacts, and abrasion. Industrial facilities and warehouses often choose self-leveling epoxy because it withstands forklifts, trolleys, and other machinery without cracking or peeling.

3. Chemical Resistance

This flooring is highly resistant to acids, oils, solvents, and cleaning chemicals, making it perfect for laboratories, factories, automotive workshops, and kitchens. The chemical-resistant layer protects the substrate and ensures long-term performance.

Internal link suggestions:

/chemical-resistant-flooring/

/industrial-floor-protection/

4. Moisture and Water Resistance

Concrete floors are prone to moisture absorption, which can cause mold, efflorescence, and damage. Self-leveling epoxy creates an impermeable layer, preventing water ingress and reducing maintenance costs.

5. Heat and UV Resistance

Some epoxy formulations include UV-resistant additives, which protect the flooring from discoloration and degradation due to sunlight exposure. This feature is especially useful for terraces, open warehouses, and commercial spaces with large windows.

Applications of Self-Leveling Epoxy Flooring

Residential Use

-

Kitchens, living rooms, and basements benefit from smooth, durable epoxy floors that are easy to clean and maintain.

-

Garages and terraces gain resistance against oil spills, water, and heavy loads.

-

Internal link: /residential-flooring-solutions/

Commercial Use

-

Offices, retail stores, and showrooms use epoxy flooring for its glossy, professional finish and low maintenance.

-

It supports high foot traffic areas and creates a visually appealing environment.

Industrial Use

-

Factories, warehouses, and workshops need durable, chemical-resistant flooring.

-

Self-leveling epoxy withstands mechanical wear, spills, and heavy equipment, ensuring the safety and longevity of the flooring.

-

Internal link: /industrial-flooring/

Special Applications

-

Food processing units

-

Pharmaceutical labs

-

Cold storage facilities

-

Automotive service centers

External reference:

https://www.flooringassociation.org/epoxy-industrial-floors/

Installation Process – Step by Step

Proper installation is crucial for optimal performance. The process typically involves:

-

Surface Preparation

Clean the concrete thoroughly, remove dust, grease, and loose particles. Minor cracks should be repaired using epoxy filler.

Internal link: /floor-preparation-guide/ -

Primer Application

Apply a suitable epoxy primer to improve adhesion and reduce air bubbles during self-leveling. -

Mixing Epoxy Resin and Hardener

Combine the two components according to manufacturer instructions. Proper mixing ensures a uniform chemical reaction and optimal curing. -

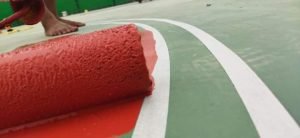

Pouring and Spreading

Pour the mixed epoxy onto the floor and spread using a trowel or squeegee. The self-leveling property allows the coating to settle into cracks and uneven areas, creating a smooth surface. -

Deaeration

Use a spiked roller to remove trapped air bubbles for a flawless finish. -

Curing

Allow the flooring to cure for 24–48 hours depending on temperature and humidity. Avoid foot traffic until fully cured. -

Optional Topcoat

Apply a clear polyurethane or epoxy topcoat for enhanced gloss, UV protection, and chemical resistance.

Advantages Over Traditional Flooring

-

Seamless Finish – Unlike tiles or carpets, epoxy flooring is joint-free.

-

Durability – Resistant to abrasion, impact, and heavy machinery.

-

Easy Cleaning & Maintenance – Smooth surface prevents dirt, mold, and bacteria accumulation.

-

Chemical Resistance – Ideal for industrial and commercial spaces.

-

Versatility – Suitable for homes, offices, factories, laboratories, and garages.

-

Cost-Effective Long-Term – Low maintenance and long lifespan make it economical.

Internal links for related solutions:

/garage-flooring/

/industrial-protection-floors/

Maintenance Tips

-

Sweep or vacuum regularly to remove dust and debris.

-

Clean spills promptly with mild detergents.

-

Avoid sharp objects to prevent scratches.

-

Inspect periodically for minor damages and repair using epoxy filler.

Proper maintenance ensures lasting performance and visual appeal.

Environmental and Safety Benefits

-

Low VOC Epoxy Options: Safe for indoor air quality.

-

Reduces Waste: Can be applied directly on existing concrete, minimizing demolition.

-

Energy Efficiency: Reflective finishes can reduce indoor heat absorption.

External reference:

https://www.greenbuildingadvisor.com/article/low-voc-epoxy-floors

Customization and Aesthetic Options

Self-leveling epoxy flooring can be customized in color, texture, and pattern:

-

Metallic epoxy for a glossy, decorative finish

-

Matte epoxy for a modern, subdued look

-

Flake or chip systems for industrial aesthetics

-

Embedded logos or branding for commercial floors

Internal link:

/decorative-epoxy-flooring/

Long-Term Benefits

-

Longevity: 10–20 years of performance with minimal maintenance.

-

Cost Savings: Reduced cleaning and repair costs.

-

Professional Appearance: Enhances property value and aesthetics.

-

Safety: Slip-resistant additives improve floor safety in wet or industrial areas.

Internal & External Linking Suggestions

-

Internal Links:

-

/industrial-flooring/

-

/residential-floor-coating/

-

/epoxy-floor-installation-guide/

-

/chemical-resistant-flooring/

-

/decorative-epoxy-flooring/

-

/garage-flooring/

-

Why Self-Leveling Epoxy Flooring is the Ultimate Solution

Self-leveling epoxy flooring has become a game-changer in modern construction and interior design. Its ability to create a smooth, durable, and aesthetically appealing surface makes it ideal for a wide range of environments. Unlike conventional flooring options like tiles, wood, or cement screed, epoxy provides a seamless, uniform finish that enhances both functionality and beauty.

For residential spaces, it adds a modern, sleek look while making cleaning and maintenance effortless. For industrial and commercial areas, its resistance to chemicals, abrasion, and mechanical loads ensures longevity and safety. Internal link suggestions:

/residential-flooring-solutions/

/industrial-flooring/

Components of Self-Leveling Epoxy Flooring

Self-leveling epoxy flooring typically consists of two main components:

-

Epoxy Resin: The base material that provides adhesion, chemical resistance, and durability.

-

Hardener: Activates a chemical reaction when mixed with resin, causing the material to cure into a solid, tough surface.

Some premium formulations also include:

-

UV Stabilizers to prevent yellowing and maintain gloss.

-

Antimicrobial additives to inhibit bacterial growth.

-

Decorative flakes or metallic pigments for aesthetic enhancements.

External reference:

https://www.epoxyflooring.org/self-leveling-epoxy/

Applications Across Various Industries

1. Residential Spaces

Self-leveling epoxy is perfect for homes seeking a modern, seamless flooring solution. It can be applied in:

-

Living rooms and lounges

-

Kitchens and dining areas

-

Basements and garages

-

Terraces and balconies

It provides a durable, easy-to-clean surface that withstands spills, moisture, and foot traffic.

Internal link suggestion:

/residential-flooring/2. Commercial Spaces

Commercial establishments benefit greatly from epoxy flooring due to its professional appearance and robustness. Common applications include:

-

Retail stores and showrooms

-

Restaurants and cafes

-

Offices and lobbies

-

Fitness centers and gyms

The flooring enhances aesthetics while being capable of handling high foot traffic.

Internal link suggestion:

/commercial-flooring/3. Industrial and Manufacturing Facilities

Industrial applications require flooring that can endure heavy machinery, chemical exposure, and mechanical wear. Self-leveling epoxy flooring is widely used in:

-

Factories and warehouses

-

Pharmaceutical laboratories

-

Cold storage facilities

-

Automotive service centers

Its chemical and abrasion resistance ensures long-term performance and minimal maintenance.

Internal link:

/industrial-floor-protection/External reference:

https://www.flooringassociation.org/epoxy-industrial-floors/

Advantages of Self-Leveling Epoxy Flooring

-

Seamless and Smooth Surface: The self-leveling property ensures a flat and uniform finish, eliminating cracks, grout lines, and uneven patches.

-

High Durability: Resistant to scratches, impacts, heavy loads, and long-term wear.

-

Chemical Resistance: Protects floors from acids, oils, solvents, and cleaning agents.

-

Moisture Protection: Acts as a barrier to prevent water damage and mold growth.

-

Thermal Resistance: Reduces heat absorption when combined with reflective coatings.

-

Customizable Aesthetics: Available in various colors, textures, metallic finishes, and embedded patterns.

-

Low Maintenance: Easy cleaning and minimal upkeep over years of usage.

Internal link:

/decorative-epoxy-flooring/

Step-by-Step Installation Guide

Step 1: Surface Preparation

Proper surface preparation is critical for strong adhesion. Concrete should be clean, dry, and free of debris or oils. Minor cracks or imperfections should be repaired with epoxy filler.

Internal link:

/floor-preparation-guide/Step 2: Primer Application

A primer layer is applied to enhance adhesion and reduce air bubbles during the self-leveling process. It also seals the concrete and prevents moisture from affecting the epoxy layer.

Step 3: Mixing Epoxy

Mix the resin and hardener according to manufacturer instructions. Ensure consistent mixing to prevent curing issues or weak spots.

Step 4: Pouring and Spreading

Pour the epoxy mixture onto the prepared surface and spread it evenly using a trowel or squeegee. The self-leveling properties allow the epoxy to fill cracks, depressions, and uneven areas automatically.

Step 5: Deaeration

Use a spiked roller to remove trapped air bubbles, ensuring a flawless, smooth finish.

Step 6: Curing

Allow the epoxy to cure for 24–48 hours, depending on temperature and humidity. Avoid foot traffic until fully hardened.

Step 7: Optional Topcoat

A protective topcoat may be applied to enhance UV resistance, chemical resistance, and gloss.

Internal link:

/epoxy-floor-installation-guide/

Maintenance Tips for Longevity

-

Sweep or vacuum regularly to remove dirt and debris.

-

Wipe spills immediately to prevent staining.

-

Avoid dragging sharp or heavy objects across the floor.

-

Inspect periodically for minor scratches or damage and repair using epoxy filler.

Internal link:

/floor-maintenance-tips/

Customization and Decorative Options

Self-leveling epoxy flooring is highly customizable to meet aesthetic and functional needs:

-

Metallic Epoxy: Creates a glossy, marble-like finish for premium interiors.

-

Flake System: Adds decorative flakes or chips for texture and durability.

-

Matte Finish: Provides a modern, subdued appearance for commercial spaces.

-

Embedded Logos or Branding: Ideal for retail stores, gyms, or showrooms.

External reference:

https://www.flooringguides.com/decorative-epoxy-floors/

Environmental and Safety Considerations

-

Low VOC Options: Eco-friendly epoxy resins improve indoor air quality.

-

Recyclable Materials: Some epoxy floors can be recycled or repurposed at end-of-life.

-

Energy Efficiency: Reflective finishes reduce heat absorption, saving on cooling costs.

Internal link:

/eco-friendly-flooring/

Benefits for Residential Clients

-

Modern, seamless look for living spaces

-

Easy to clean and maintain

-

Resistant to spills, scratches, and moisture

-

Enhances property value and appeal

Benefits for Commercial and Industrial Clients

-

Handles heavy foot traffic and machinery loads

-

Chemical-resistant for factories, labs, and workshops

-

Low maintenance reduces operational costs

-

Customizable designs for branding and professional appearance

Cost-Effectiveness of Self-Leveling Epoxy Flooring

While the initial installation cost may be higher than traditional flooring, the long lifespan and minimal maintenance make it a cost-effective long-term solution. Factories, warehouses, and offices save on:

-

Frequent repairs

-

Cleaning labor

-

Replacement costs

Internal link:

/cost-effective-flooring-solutions/

Frequently Asked Questions (FAQs)

Q1: How long does self-leveling epoxy flooring last?

A1: With proper installation and maintenance, it can last 10–20 years.Q2: Can epoxy flooring be applied over tiles?

A2: Yes, but the tiles must be cleaned, degreased, and leveled properly.Q3: Is epoxy flooring safe for homes with children and pets?

A3: Yes, especially if low-VOC or non-toxic epoxy is used.Q4: How soon can I walk on the floor after installation?

A4: Typically 24–48 hours, depending on ambient temperature and humidity.Q5: Can epoxy floors be repaired if damaged?

A5: Minor scratches or chips can be repaired with epoxy filler for seamless restoration.Internal link:

/epoxy-flooring-faq/

Internal and External Linking Suggestions

Internal Links:

-

/residential-flooring-solutions/

-

/industrial-flooring/

-

/epoxy-floor-installation-guide/

-

/decorative-epoxy-flooring/

-

/floor-preparation-guide/

-

/eco-friendly-flooring/

-

/floor-maintenance-tips/

-

/cost-effective-flooring-solutions/

-

-

-

Why Choose Self-Leveling Epoxy Flooring from Robust Construction Chemicals

When it comes to high-quality flooring solutions, Robust Construction Chemicals offers premium self-leveling epoxy flooring designed for durability, smoothness, and long-term performance. Our products are trusted across residential, commercial, and industrial applications in Pakistan. Using only high-grade materials, our epoxy flooring ensures crack-free, seamless, and long-lasting surfaces that can withstand heavy traffic, chemical exposure, and environmental wear.

Internal link: https://robustconstructionchemical.com/self-leveling-epoxy-flooring

Residential Applications

Self-leveling epoxy flooring is ideal for modern homes, offering a sleek, seamless surface that enhances interior aesthetics. Some common applications include:

-

Living rooms and lounges for a smooth, elegant look

-

Kitchens and bathrooms for easy cleaning and stain resistance

-

Garages and terraces for waterproof, durable protection

-

Basements and storage areas to prevent moisture damage

Internal link: https://robustconstructionchemical.com/residential-flooring

Commercial and Office Spaces

In offices, showrooms, restaurants, or retail outlets, self-leveling epoxy flooring not only improves appearance but also reduces maintenance costs. Its seamless surface prevents dirt accumulation and makes cleaning fast and efficient.

Internal link: https://www.facebook.com/robustconstructionchemicals

Benefits for commercial spaces include:

-

High resistance to foot traffic and rolling equipment

-

Long-lasting durability in high-use areas

-

Easy integration with company branding using customizable colors and logos

Industrial and Factory Floors

Factories, warehouses, and production facilities require heavy-duty flooring solutions. Self-leveling epoxy from Robust Construction Chemicals withstands:

-

Heavy machinery loads

-

Chemical spills and corrosion

-

Abrasion from forklifts, trolleys, and industrial traffic

Internal link: https://robustconstructionchemical.com/industrial-flooring

Our team ensures professional installation for optimal performance, protecting the facility floors for years without frequent repairs.

External link reference: https://www.flooringassociation.org/epoxy-industrial-floors

Step-by-Step Installation Process

A correct installation guarantees maximum longevity and performance. The steps include:

-

Surface Cleaning & Preparation – Remove dirt, grease, and loose particles for optimal bonding.

Internal link: https://robustconstructionchemical.com/floor-preparation-guide -

Primer Application – Enhances adhesion and seals the concrete base.

-

Mixing Epoxy Resin & Hardener – Ensure uniform mixing for a smooth, crack-free floor.

-

Pouring & Spreading – Self-leveling epoxy flows to fill minor cracks, creating a uniform surface.

-

Bubble Removal – Use a spiked roller for a flawless finish.

-

Curing Time – Typically 24–48 hours before walking or placing heavy objects.

-

Optional Topcoat – Enhances gloss, chemical resistance, and UV stability.

Internal link: https://robustconstructionchemical.com/epoxy-floor-installation

Maintenance Tips for Longevity

-

Sweep or vacuum regularly to remove dust and debris.

-

Wipe spills immediately to prevent stains.

-

Avoid dragging heavy or sharp objects across the floor.

-

Minor scratches can be repaired using epoxy fillers.

Internal link: https://robustconstructionchemical.com/floor-maintenance-tips

Customizations and Decorative Options

Self-leveling epoxy flooring can be fully customized to meet design or branding needs. Options include:

-

Metallic epoxy for a modern, glossy finish

-

Decorative flakes for industrial aesthetics

-

Embedded logos for commercial branding

-

Matte or semi-gloss finishes for residential elegance

Internal link: https://robustconstructionchemical.com/decorative-epoxy-flooring

External reference: https://www.flooringguides.com/decorative-epoxy-floors

Environmental Benefits

-

Low VOC formulations improve indoor air quality.

-

Can be applied over existing concrete surfaces, reducing waste and demolition debris.

-

Reflective epoxy floors reduce heat absorption, lowering cooling costs.

Internal link: https://robustconstructionchemical.com/eco-friendly-flooring

Why Robust Construction Chemicals?

Choosing Robust Construction Chemicals ensures:

-

High-quality materials sourced for maximum performance

-

Professional installation for both residential and industrial floors

-

Customized solutions based on client requirements

-

Support and guidance via website and Facebook for queries, tips, and product information

Internal link: https://www.facebook.com/robustconstructionchemicals

Internal link: https://robustconstructionchemical.com

Long-Term Benefits

-

Durability: Resistant to abrasion, chemicals, moisture, and temperature changes.

-

Aesthetics: Seamless, smooth, and customizable appearance for any space.

-

Low Maintenance: Easy cleaning, no frequent repairs.

-

Safety: Slip-resistant additives improve safety in wet or industrial areas.

Internal link: https://robustconstructionchemical.com/self-leveling-epoxy-flooring

Contact & Support

For more information or to request a free consultation, visit:

Our team provides professional guidance on product selection, installation, and maintenance, ensuring the best results for every project.

-

Smooth and Seamless Finish

Self-leveling epoxy spreads uniformly across floors, creating a smooth, continuous surface without grout lines or joints. This not only enhances aesthetics but also prevents dirt and bacteria accumulation, making it ideal for hospitals, laboratories, and food processing areas.