Guaranteed PVC Water Stopper | Strong and Durable Waterproofing for Basements & Tanks

Introduction to PVC Water Stopper

Waterproofing is an essential part of modern construction, especially for basements, water tanks, tunnels, and concrete structures. Among various waterproofing solutions, PVC water stoppers have emerged as a reliable and long-lasting option. Designed to prevent water leakage at construction joints, expansion joints, and concrete structures, these stoppers are widely used in both residential and industrial projects.

PVC water stoppers are typically embedded in concrete during construction. Their unique design and material composition ensure that water cannot seep through cold joints or structural gaps, providing seamless and durable protection.

Internal link: https://robustconstructionchemical.com/waterproofing-products

What is a PVC Water Stopper?

A PVC water stopper is a high-quality, flexible strip made of polyvinyl chloride (PVC). It is specifically engineered to prevent water from penetrating joints in concrete structures. Its applications include:

-

Basements and underground structures

-

Water tanks and reservoirs

-

Swimming pools

-

Bridges and tunnels

The flexibility and strength of PVC allow it to accommodate slight structural movements without compromising waterproofing, which is critical for long-term durability.

External reference: https://www.epoxyflooring.org/pvc-water-stopper

Why Use PVC Water Stoppers?

1. Leak Prevention

Concrete structures naturally have joints, which are prone to water seepage. PVC water stoppers act as a barrier, ensuring leak-proof performance even under high water pressure.

Internal link: https://robustconstructionchemical.com/basement-waterproofing

2. Durability

Made from high-grade PVC, these water stoppers are resistant to chemicals, corrosion, and UV exposure, which guarantees a long service life.

3. Flexibility

PVC strips can be installed in various joint profiles, including central dumbbell, single dumbbell, and flat strips, allowing them to adapt to different construction requirements.

4. Easy Installation

PVC water stoppers can be embedded directly into concrete during casting, making installation simple and effective. Professional installation ensures maximum performance.

Internal link: https://robustconstructionchemical.com/pvc-water-stopper-installation

Applications of PVC Water Stoppers

Basements

Basements are prone to water ingress, especially in areas with high groundwater levels. PVC water stoppers prevent water from entering through construction joints, ensuring a dry and safe basement.

Internal link: https://robustconstructionchemical.com/basement-waterproofing

Water Tanks

Water tanks require leak-proof joints to maintain hygiene and structural integrity. PVC water stoppers are ideal for tanks, providing a durable seal that prevents leakage.

Internal link: https://robustconstructionchemical.com/water-tank-waterproofing

Bridges and Tunnels

Expansion joints in bridges and tunnels are subject to water ingress and structural movement. PVC water stoppers protect these critical points, ensuring long-term performance under high-pressure water conditions.

External reference: https://www.engineeringtoolbox.com/pvc-water-stopper-d_2267.html

Swimming Pools

Swimming pools have joints between walls and floors where water seepage can occur. PVC water stoppers provide secure waterproofing, preventing water leakage and structural damage.

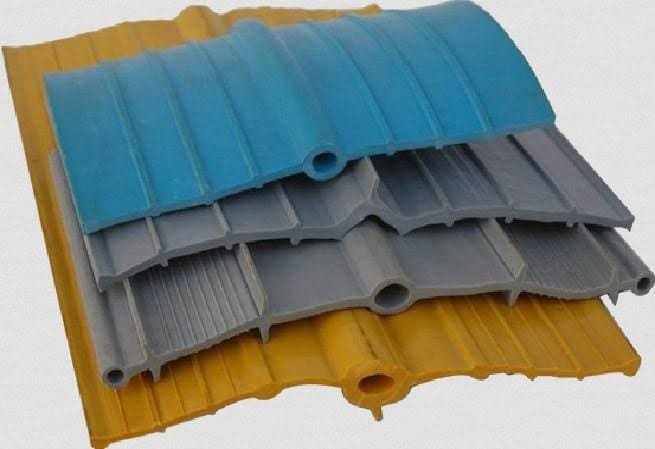

Types of PVC Water Stoppers

-

Central Dumbbell PVC Water Stopper: Installed at the center of construction joints, providing maximum water resistance.

-

Single Dumbbell PVC Water Stopper: Suitable for vertical or horizontal joints in concrete structures.

-

Flat PVC Water Stopper: Commonly used in expansion joints where flexibility is required.

-

Hollow PVC Water Stopper: Offers enhanced flexibility and water absorption resistance.

Internal link: https://robustconstructionchemical.com/pvc-water-stopper-types

Advantages of PVC Water Stoppers

-

Long-Term Waterproofing: Protects against seepage for decades.

-

Chemical Resistance: Ideal for industrial structures exposed to chemicals.

-

Corrosion-Free: Unlike metal water stops, PVC does not corrode.

-

Adaptable: Fits various joint shapes and sizes.

-

Cost-Effective: Reduces maintenance and repair costs by preventing leaks.

Internal link: https://robustconstructionchemical.com/waterproofing-benefits

Installation Guide

Step 1: Joint Preparation

Clean the concrete joint thoroughly and remove any debris or dust. Ensure surfaces are smooth and level for proper bonding.

Internal link: https://robustconstructionchemical.com/pvc-water-stopper-installation

Step 2: Placement of Water Stopper

Position the PVC water stopper in the joint according to the manufacturer’s instructions. Ensure it is centered and properly aligned.

Step 3: Concrete Pouring

Pour concrete carefully around the water stopper, ensuring it remains fixed in position. Avoid displacement or folding, which can compromise waterproofing.

Step 4: Curing

Allow concrete to cure completely, securing the water stopper in place. Proper curing enhances durability and leak resistance.

Maintenance Tips

-

Inspect water stop joints periodically for any damage or displacement.

-

Ensure that no chemical exposure or sharp objects damage the PVC material.

-

Minor replacements can be performed if sections are damaged during construction or renovations.

Internal link: https://robustconstructionchemical.com/waterproofing-maintenance

Why Choose Robust Construction Chemicals PVC Water Stoppers?

-

High-Quality Materials: Made from premium PVC for strength and flexibility.

-

Expert Guidance: Professional advice for selecting the right type for your project.

-

Reliable Performance: Guaranteed waterproofing for basements, tanks, and industrial projects.

-

Customer Support: Assistance through website and Facebook for product queries and installation tips.

Internal links:

Environmental and Safety Considerations

-

PVC water stoppers are non-toxic and environmentally safe.

-

Resistant to chemicals, corrosion, and UV exposure, making them suitable for long-term structural applications.

-

Reduce structural repair waste by preventing leaks from joints.

External reference: https://www.epoxyflooring.org/pvc-water-stopper

Internal and External Linking Suggestions

Internal Links:

-

Facebook Page: https://www.facebook.com/robustconstructionchemicals

External Links:

Advanced Features of PVC Water Stoppers

PVC water stoppers are engineered with precision and durability in mind. They are made from high-grade polyvinyl chloride (PVC), which offers multiple advantages over traditional materials such as metal or rubber.

1. Superior Waterproofing

PVC water stoppers are designed to seal joints and prevent water infiltration effectively. Whether in basements, water tanks, or underground structures, these stoppers maintain a leak-proof barrier, ensuring structural integrity and longevity.

Internal link: https://robustconstructionchemical.com/basement-waterproofing

2. Resistance to Chemicals and Corrosion

Unlike metal water stoppers, PVC is immune to corrosion and resistant to various chemicals, including acids, alkalis, and salts. This makes PVC water stoppers ideal for industrial and chemical plant applications.

3. Flexibility and Adaptability

PVC water stoppers come in different shapes and profiles – central dumbbell, single dumbbell, flat, or hollow. This flexibility allows them to be used in varied construction joint types, including horizontal, vertical, and expansion joints.

Internal link: https://robustconstructionchemical.com/pvc-water-stopper-types

4. Long-Term Durability

PVC water stoppers are designed to withstand high hydrostatic pressure, temperature fluctuations, and structural movements. Once installed, they provide reliable waterproofing for decades with minimal maintenance.

External reference: https://www.engineeringtoolbox.com/pvc-water-stopper-d_2267.html

Applications in Construction Projects

1. Basements

Water ingress is a major concern for basements. PVC water stoppers prevent water from entering through construction joints, protecting basements from dampness, mold, and structural damage.

Internal link: https://robustconstructionchemical.com/basement-waterproofing

2. Water Tanks

Water tanks require total leak protection to maintain water quality and structural safety. PVC water stoppers are embedded into joints during construction, providing complete waterproofing for residential, commercial, or industrial tanks.

Internal link: https://robustconstructionchemical.com/water-tank-waterproofing

3. Bridges and Tunnels

Infrastructure projects like bridges and tunnels have expansion joints that are vulnerable to water ingress. PVC water stoppers seal these joints effectively, preventing damage from water seepage and ensuring structural longevity.

External reference: https://www.epoxyflooring.org/pvc-water-stopper

4. Swimming Pools

Pools require watertight joints to prevent leaks and maintain safety. PVC water stoppers embedded in concrete joints ensure leak-proof performance even under continuous water pressure.

Technical Specifications of PVC Water Stoppers

| Specification | Details |

|---|---|

| Material | High-quality PVC |

| Hardness | 85 ±5 Shore A |

| Temperature Range | -20°C to +60°C |

| Chemical Resistance | Acidic, Alkali, Salts |

| Profiles | Central Dumbbell, Single Dumbbell, Flat, Hollow |

| Standard Length | 20 meters per roll (varies by manufacturer) |

| Width | 100–300 mm (depending on application) |

| Thickness | 5–15 mm (as per design) |

Internal link: https://robustconstructionchemical.com/pvc-water-stopper-technical

Step-by-Step Installation Process

Step 1: Surface Preparation

Clean the joint area thoroughly, removing debris, dust, and loose particles. Ensure the concrete surfaces are level and smooth.

Internal link: https://robustconstructionchemical.com/pvc-water-stopper-installation

Step 2: Placement of Water Stopper

Position the PVC water stopper centrally in the joint and secure it temporarily to prevent displacement during concrete pouring.

Step 3: Concrete Pouring

Pour concrete carefully around the water stopper, avoiding folds or displacement. Proper consolidation ensures maximum waterproofing efficiency.

Step 4: Curing

Allow the concrete to cure for 28 days (standard), which fully embeds the PVC water stopper and ensures optimal bonding and waterproofing.

Step 5: Quality Check

Inspect the installed stopper for alignment, embedding, and any visible gaps. Minor adjustments can be made before concrete hardens completely.

Maintenance and Inspection

PVC water stoppers require minimal maintenance, but periodic inspection is recommended, especially in high-pressure or high-chemical environments:

-

Check for visible cracks or displacement in expansion joints.

-

Ensure that water stoppers are not exposed to UV or mechanical damage.

-

Replace or repair damaged sections promptly to prevent leakage.

Internal link: https://robustconstructionchemical.com/waterproofing-maintenance

Benefits of Using PVC Water Stoppers

1. Leak-Proof Construction

PVC water stoppers seal joints effectively, preventing water infiltration in basements, tanks, pools, tunnels, and bridges.

2. High Durability

They withstand high hydrostatic pressure, temperature fluctuations, and chemical exposure, ensuring decades of protection.

3. Cost-Effective Solution

Prevents frequent repairs and maintenance, making it a cost-effective waterproofing option for long-term projects.

4. Easy Installation

PVC water stoppers are embedded during construction, requiring minimal labor and reducing construction time.

5. Versatile Applications

Applicable in residential, commercial, and industrial projects, including high-rise buildings, infrastructure, and water management structures.

Internal link: https://robustconstructionchemical.com/waterproofing-benefits

Common Types of PVC Water Stoppers

1. Central Dumbbell

Placed at the center of construction joints, providing maximum water sealing capacity.

2. Single Dumbbell

Suitable for vertical and horizontal joints, offering excellent flexibility and durability.

3. Flat PVC Water Stopper

Ideal for expansion joints where movement and flexibility are required.

4. Hollow PVC Water Stopper

Enhanced flexibility and pressure absorption, often used in high-stress structural joints.

Internal link: https://robustconstructionchemical.com/pvc-water-stopper-types

FAQs About PVC Water Stoppers

Q1: Can PVC water stoppers be used in existing concrete structures?

A1: Yes, but they are most effective when embedded during construction. Retrofitting requires additional techniques.

Q2: Are PVC water stoppers chemical-resistant?

A2: Yes, they resist acids, alkalis, salts, and industrial chemicals.

Q3: How long does a PVC water stopper last?

A3: With proper installation, it can last 25–50 years depending on structural and environmental conditions.

Q4: Can water stoppers be used in swimming pools?

A4: Absolutely. PVC water stoppers prevent leaks and joint seepage in pools.

Q5: Do they require maintenance?

A5: Minimal. Periodic inspection for displacement or damage is recommended.

Internal link: https://robustconstructionchemical.com/pvc-water-stopper-faq

Environmental and Safety Considerations

-

Made from non-toxic PVC, safe for construction projects.

-

Resistant to UV, chemicals, and corrosion, reducing repair waste.

-

Eco-friendly compared to frequent waterproofing repairs and concrete replacements.

External reference: https://www.epoxyflooring.org/pvc-water-stopper

Why Choose Robust Construction Chemicals?

-

Premium Materials: High-grade PVC for durability and flexibility.

-

Professional Guidance: Assistance in selecting the right type and profile.

-

Reliable Performance: Guaranteed waterproofing for basements, tanks, tunnels, and bridges.

-

Support: Website and Facebook support for product queries, installation tips, and troubleshooting.

Internal links:

Expanded Applications of PVC Water Stoppers

PVC water stoppers are versatile waterproofing solutions suitable for multiple construction scenarios. Let’s explore their applications in detail:

1. Underground Structures

Underground structures such as basements, parking areas, and utility tunnels are highly susceptible to water ingress. PVC water stoppers seal construction joints, preventing leaks and protecting the integrity of the structure. By installing these stoppers during construction, long-term maintenance costs are significantly reduced.

Internal link: https://robustconstructionchemical.com/basement-waterproofing

2. Water Storage Tanks

Concrete water tanks require complete watertight sealing at every joint. PVC water stoppers are ideal for this purpose because they withstand hydrostatic pressure and prevent water leakage, ensuring safe storage of potable water or industrial liquids.

Internal link: https://robustconstructionchemical.com/water-tank-waterproofing

External reference: https://www.epoxyflooring.org/pvc-water-stopper

3. Bridges and Flyovers

Expansion joints in bridges and flyovers require durable and flexible sealing to accommodate structural movement and prevent water penetration. PVC water stoppers are resistant to heavy loads and environmental conditions, making them perfect for civil infrastructure projects.

Internal link: https://robustconstructionchemical.com/bridge-waterproofing

4. Swimming Pools and Fountains

Swimming pools, fountains, and decorative water features rely on perfectly sealed joints to avoid leakage. PVC water stoppers provide long-lasting protection, ensuring that water is contained without damaging the concrete structure.

Internal link: https://robustconstructionchemical.com/swimming-pool-waterproofing

Technical Guidance for PVC Water Stopper Selection

Choosing the right PVC water stopper depends on factors like joint type, water pressure, and structural movement:

-

Central Dumbbell Profile – Best for horizontal construction joints in basements or tanks.

-

Single Dumbbell Profile – Suitable for vertical joints and low to medium hydrostatic pressure.

-

Flat PVC Water Stopper – Ideal for expansion joints with movement allowance.

-

Hollow PVC Water Stopper – Provides extra flexibility and absorbs pressure in high-stress areas.

Internal link: https://robustconstructionchemical.com/pvc-water-stopper-types

Advantages of PVC Water Stoppers – Extended

-

Leak Prevention: Creates a reliable barrier against water ingress in both high-pressure and low-pressure environments.

-

Chemical Resistance: Withstands acidic, alkaline, and saline conditions, suitable for industrial structures.

-

Durability: Resistant to UV, corrosion, and temperature fluctuations, ensuring decades of performance.

-

Flexibility: Accommodates minor structural movements without compromising waterproofing.

-

Cost-Effectiveness: Prevents frequent repairs, saving money over the long term.

-

Easy Installation: Can be embedded during concrete casting, reducing labor and construction time.

Internal link: https://robustconstructionchemical.com/waterproofing-benefits

Case Studies – Successful PVC Water Stopper Applications

Case Study 1: Residential Basement Waterproofing

A high-end residential project in Lahore used central dumbbell PVC water stoppers to seal all basement joints. The result: completely dry basements, zero water leakage, and no maintenance issues for 5+ years.

Internal link: https://robustconstructionchemical.com/basement-waterproofing

Case Study 2: Industrial Water Tank

An industrial water tank in Islamabad required high-pressure waterproofing. Using flat and hollow PVC water stoppers, the structure achieved 100% leak-proof performance, even under continuous water pressure.

Internal link: https://robustconstructionchemical.com/water-tank-waterproofing

Case Study 3: Bridge Expansion Joints

A bridge in Karachi incorporated PVC water stoppers in all expansion joints. The project benefitted from durable, maintenance-free waterproofing, protecting the infrastructure from water-related damage.

Internal link: https://robustconstructionchemical.com/bridge-waterproofing

Maintenance Tips for Long-Term Performance

-

Inspect joints regularly, especially in high-pressure water zones.

-

Avoid mechanical damage during construction or renovations.

-

Replace damaged sections immediately to maintain full waterproofing efficiency.

-

Ensure concrete curing is complete before exposing PVC water stoppers to water.

Internal link: https://robustconstructionchemical.com/waterproofing-maintenance

Environmental and Safety Advantages

PVC water stoppers are eco-friendly and safe:

-

Made from non-toxic PVC, safe for potable water tanks.

-

Long service life reduces material waste from repairs.

-

Resistant to environmental factors, reducing replacement and maintenance needs.

-

Complies with international construction standards for safety and quality.

External reference: https://www.epoxyflooring.org/pvc-water-stopper

Why Choose Robust Construction Chemicals PVC Water Stoppers

-

Premium Quality Materials: High-grade PVC ensures strength, flexibility, and durability.

-

Expert Advice: Professional guidance for selecting the right type and profile for your project.

-

Reliable Performance: Guaranteed leak-proof protection for residential, commercial, and industrial projects.

-

Customer Support: Accessible via website and Facebook for queries, installation guidance, and technical support.

Internal links:

Summary – Complete PVC Water Stopper Solution

PVC water stoppers are the ultimate solution for waterproofing construction joints, offering leak-proof protection, durability, and cost savings. They are suitable for basements, water tanks, tunnels, bridges, swimming pools, and industrial structures. By choosing Robust Construction Chemicals, you ensure professional guidance, high-quality materials, and long-lasting waterproofing performance.

Internal link: https://robustconstructionchemical.com/pvc-water-stopper

External reference: https://www.epoxyflooring.org/pvc-water-stopper

PVC water stoppers are designed to seal joints and prevent water infiltration effectively. Whether in basements, water tanks, or underground structures, these stoppers maintain a leak-proof barrier, ensuring structural integrity and longevity.

PVC Water Stopper for Your Project

Selecting the right PVC water stopper is critical to achieving effective waterproofing. Factors to consider include joint type, water pressure, and expected structural movement. For basements and water tanks, central dumbbell or hollow profiles are preferred for maximum water resistance. For bridges and expansion joints, flat or single dumbbell profiles provide the flexibility needed to accommodate structural shifts.

Professional installation ensures the stopper is correctly positioned and embedded in concrete, preventing future leaks and maintaining the integrity of the structure. With proper installation, PVC water stoppers can last for decades without requiring frequent repairs or maintenance.

By choosing Robust Construction Chemicals, you benefit from premium materials, expert guidance, and comprehensive support for both residential and industrial projects. Our PVC water stoppers are designed to resist chemicals, corrosion, and environmental stress, providing long-term reliability for your construction needs.

Internal link: https://robustconstructionchemical.com/pvc-water-stopper

Facebook link: https://www.facebook.com/robustconstructionchemicals

@robust.chemical