Robust Backer Rod Does

-

Fills gaps and joints before applying sealant (like silicone, polyurethane, or latex).

-

Controls sealant depth, ensuring the sealant doesn’t bond to three sides (which prevents cracking).

-

Helps form the proper hourglass shape of sealant in expansion joints.

-

Reduces sealant usage, saving material.

-

Improves joint flexibility, allowing movement without failing.

Where It’s Used

-

Expansion joints in concrete (sidewalks, driveways, slabs)

-

Gaps around windows and doors

-

Log homes (between logs)

-

Precast concrete connections

-

Curtain walls and glazing applications

Types

-

Closed-cell: Most common. Doesn’t absorb water; ideal for exterior joints.

-

Open-cell: More flexible; allows air to escape when sealant is applied.

-

Bi-cellular: Mix of both; flexible like open-cell but resistant to water like closed-cell.

-

What Is a Backer Rod?

A backer rod is a flexible foam rope used as a backing material in joints and gaps before applying sealants. It helps control sealant depth, improves adhesion, and ensures the joint performs correctly under movement or environmental stress.

Functions of a Backer Rod

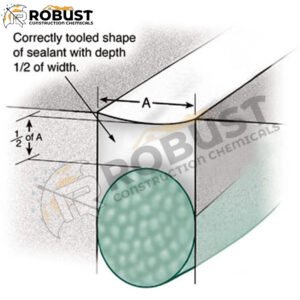

1. Controls Sealant Depth

-

Ensures the ideal depth-to-width ratio for sealant.

-

Prevents overfilling, which can cause premature failure.

2. Prevents Three-Sided Adhesion

-

Sealant should bond only to two sides of a joint.

-

Backer rods stop sealant from sticking at the bottom, improving flexibility.

3. Forms Proper Sealant Geometry

-

Creates the desired hourglass shape, which allows stretching and compression.

4. Reduces Sealant Consumption

-

Fills most of the joint volume so less sealant is required.

5. Improves Joint Performance

-

Enhances elasticity and long-term durability.

-

Helps the joint handle expansion, contraction, and vibration.

Types of Backer Rods

1. Closed-Cell Backer Rod

-

Made of dense, watertight foam.

-

Does not absorb water.

-

Best for outdoor joints, concrete, and wet environments.

-

Suitable for use with most sealant types.

2. Open-Cell Backer Rod

-

Softer, more compressible foam with interconnected air pockets.

-

Allows air to escape when sealant is applied, reducing bubbles.

-

Ideal for deep or irregular joints.

3. Bi-Cellular Backer Rod

-

Hybrid of open- and closed-cell foam.

-

Flexible like open-cell but resists moisture like closed-cell.

-

Versatile and commonly used in construction and glazing.

Common Applications

1. Concrete Expansion Joints

-

Sidewalks

-

Driveways

-

Garage floors

-

Building foundations

2. Window and Door Installations

-

Helps achieve airtight, weatherproof seals.

3. Glazing and Curtain Walls

-

Used behind structural and weatherproof sealants.

4. Log Home Construction

-

Placed between logs before chinking.

5. Precast Concrete Panels

-

Ensures proper sealing between segments.

How to Choose the Right Robust Backer Rod

1. Measure Joint Width

Select a rod 25–50% larger than the joint width for a snug fit.

2. Choose Based on Conditions

-

Exterior/wet areas: closed-cell or bi-cellular

-

Deep or irregular joints: open-cell

-

High-movement joints: flexible open- or bi-cellular

3. Consider Sealant Compatibility

Nearly all backer rods work with:

-

Polyurethane

-

Silicone

-

Latex-based sealants

-

Butyl sealants

Installation Guide

Step 1: Clean the Joint

Remove debris, old sealant, dust, or moisture.

Step 2: Insert the Backer Rod

-

Use a blunt tool (e.g., a roller or putty knife).

-

Do not puncture closed-cell rods.

Step 3: Achieve Proper Depth

Ideal depth is typically:

-

Sealant depth = ½ the joint width

-

Minimum depth: ¼ inch (6 mm)

Step 4: Apply Sealant

-

Smooth the sealant to create a uniform surface.

-

Ensure good adhesion on both sides.

Advantages of Backer Rods

-

Reduces long-term maintenance

-

Ensures stronger, longer-lasting joints

-

Improves energy efficiency around windows/doors

-

More cost-effective by reducing sealant use

-

“Backer rods provide critical joint backing for sealants, improving flexibility, reducing material use, and ensuring proper sealant geometry in construction applications.”

5. Marketing Tone

“Upgrade your sealing performance with backer rods—designed to reduce sealant waste, prevent cracking, and deliver long-lasting joint protection.”

-

A backer rod is one of the simplest yet most important materials used in modern construction, sealing, and joint-filling applications. Despite its lightweight appearance, this cylindrical foam rod plays a crucial structural and functional role in ensuring that sealants perform properly, last longer, and withstand building movement, environmental exposure, and thermal expansion. Whether used in concrete joints, window frames, log homes, or glazing systems, the backer rod is an unseen component that makes high-quality sealing possible.

This comprehensive guide explores everything you need to know about backer rods—definitions, functions, types, applications, selection criteria, installation methods, compatibility, industry standards, and troubleshooting. If you work in construction, masonry, caulking, waterproofing, or building repair, this guide provides a full understanding of how to select and use backer rods effectively.

1. What Is a Backer Rod?

A backer rod is a flexible, cylindrical foam material inserted into a joint or gap before applying sealant. It acts as a backing material that provides depth control, improves sealant adhesion, promotes flexibility, and minimizes material waste. Backer rods are typically made from polyethylene (PE) or polyurethane (PU) foam and come in a variety of densities, diameters, and cell structures.

Although simple in design, their purpose is multifaceted. By establishing the proper shape and depth of sealant joints, backer rods significantly influence the performance and reliability of sealants. Without a backer rod, sealants may adhere to too many surfaces, cure too thick, form voids, or fail prematurely due to uncontrolled tension during movement.

Backer rods are available in styles such as closed-cell, open-cell, and bi-cellular, each offering unique mechanical and moisture-resistance properties. Their lightweight nature, flexibility, and compressibility allow them to adapt to irregular surfaces and remain stable over long periods—even in harsh weather conditions.

2. Why Backer Rods Are Essential in Construction

Backer rods perform several critical functions that directly impact the longevity and performance of sealed joints.

2.1 Controls Sealant Depth

The thickness of sealant in a joint affects its flexibility and adhesion. If sealant is applied too thick, it becomes stiff and prone to cracking. If too thin, it may split or fail to expand and contract. A backer rod provides a consistent, predictable base that limits sealant depth and ensures compliance with industry standards.

2.2 Prevents Three-Sided Adhesion

Sealants are designed to bond to two sides of a joint only. If they bond to the bottom (creating a three-sided adhesion), movement stresses are distributed incorrectly, leading to premature failure. Backer rods create a “bond-breaker” effect, preventing adhesion on the bottom surface and allowing the sealant to stretch freely.

2.3 Establishes Proper Joint Geometry

Optimal sealant performance requires an hourglass-shaped profile, wider at the top and thinner in the center. The shape maximizes elasticity and absorbs movement. Backer rods shape the joint so that sealants form this ideal profile naturally.

2.4 Reduces Sealant Waste

Backer rods fill the majority of the joint’s depth, reducing the volume of expensive sealant needed. This is especially significant in large joints and long expansion gaps, where sealant costs can be high.

2.5 Enhances Flexibility and Movement Capacity

Buildings expand and contract due to temperature changes, loads, vibrations, and settling. Joints sealed without backer rods often become rigid and brittle. Backer rods allow joints to move without damaging the sealant.

2.6 Improves Air, Water, and Vapor Sealing

Whether sealing window perimeters or concrete slabs, backer rods enhance the overall weatherproofing system by providing consistent depth and sealant contact.

2.7 Facilitates Faster Installation

By providing a clear base and filling voids, backer rods make sealant application easier, cleaner, and faster for professionals.

3. Types of Backer Rods

Different construction scenarios require different backer rod properties. Below are the main categories found in the industry.

3.1 Closed-Cell Backer Rod

Closed-cell backer rods consist of dense foam with non-interconnected cells. Key characteristics:

-

Water-resistant

-

High compression resistance

-

Ideal for exterior applications

-

Suitable for cold conditions

-

Provides excellent insulation

-

Compatible with most sealants

Applications include:

concrete expansion joints, pavements, driveways, precast panels, masonry gaps.Closed-cell rods must be handled carefully to avoid puncturing, which may lift air and expand under sealant.

3.2 Open-Cell Backer Rod

Open-cell rods use soft, breathable foam:

-

Highly compressible

-

Allows trapped air to escape as sealant is applied

-

Ideal for deep joints

-

Flexible and easy to install

-

Not water-resistant—absorbs moisture

Common uses include interior joints, log homes, and areas where depth is more important than moisture exclusion.

3.3 Bi-Cellular Backer Rod

Bi-cellular (hybrid) backer rods blend open- and closed-cell structures:

-

Good flexibility

-

Moderately water-resistant

-

Suitable for both interior and exterior

-

Easier to compress than closed-cell rods

They are widely used for general-purpose construction.

3.4 Round vs. Slit Backer Rods

Some manufacturers produce slit variants that offer improved flexibility and reduce trapped air. Round rods are the standard and most commonly used.

4. Where Backer Rods Are Used: Major Applications

Backer rods are used across a wide range of industries and projects.

4.1 Concrete Expansion Joints

Concrete expands and contracts due to temperature fluctuations. Backer rods maintain joint width and provide depth control for sealant in:

-

Sidewalks

-

Driveways

-

Parking lots

-

Industrial floors

-

Bridges

-

Concrete slabs

4.2 Door and Window Installations

Backer rods help create airtight, watertight seals, improving energy efficiency. They prevent draft infiltration and reduce sound penetration.

4.3 Building Envelopes and Curtain Walls

In façade systems, backer rods serve as backing for high-performance silicone sealants used in:

-

Curtain wall glazing

-

Structural glazing

-

Weather seals around panels

4.4 Precast Concrete and Masonry Walls

Used between precast elements to accommodate thermal movement.

4.5 Log Homes

In log construction, rods are inserted between logs before chinking, preventing sealant overuse and providing flexibility.

4.6 HVAC Penetrations and Mechanical Joints

Backer rods help seal around ductwork, pipes, and cable penetrations.

4.7 Pool and Wet Area Sealing

Closed-cell rods are used in high-moisture environments with compatible sealants.

5. Technical Considerations and Standards

Backer rods are governed by several building and construction standards:

-

ASTM C1330: Standard specification for backer materials

-

ASTM C1193: Guide for use of joint sealants

-

ASTM C834 / C920: Sealant compatibility standards

-

ISO 11600: Classification of sealants

Key parameters include:

-

Density

-

Compression resistance

-

Recovery after compression

-

Moisture absorption

-

Temperature tolerance

-

Chemical compatibility

Compliance with these standards ensures durability and performance.

6. Choosing the Right Backer Rod

6.1 Joint Width and Depth

Correct sizing is essential. The rod should be 25–50% larger than the joint width for a snug fit.

6.2 Exposure Conditions

-

Exterior + moisture: closed-cell or bi-cellular

-

Deep interior joints: open-cell

-

High movement: flexible bi-cellular or open-cell

6.3 Sealant Type

Backer rods are compatible with:

-

Polyurethane

-

Silicone

-

Latex

-

Butyl

-

Acrylic

-

Hybrid sealants

Avoid solvents that attack PE foam.

6.4 Temperature and Environmental Factors

Choose materials that remain stable across the expected temperature range.

7. How to Install a Backer Rod (Step-by-Step)

7.1 Preparation

-

Clean joint surfaces

-

Remove old sealants

-

Ensure the joint is dry

-

Inspect for damage or irregularities

7.2 Rod Insertion

Tools: blunt paddles, rollers, or simple fingers.

Steps:-

Cut rod to length slightly longer than joint

-

Compress and insert into the joint

-

Place at correct depth (typically half the joint width)

-

Avoid puncturing closed-cell rods

7.3 Apply Sealant

-

Gun sealant at a steady pace

-

Ensure full adhesion to the two sides

-

Tool the sealant for a smooth finish

-

Allow proper curing time

8. Advantages of Using Backer Rods

-

Extended sealant life

-

Cost savings by reducing sealant use

-

Improved aesthetics

-

Enhanced joint movement

-

Better air and moisture sealing

-

Faster installation

-

More reliable performance under stress

9. Common Mistakes and How to Avoid Them

Incorrect Rod Size

Too small = loose fit → sealant flows behind

Too large = difficult insertion → rod damagePuncturing Closed-Cell Rod

Leads to bubble formation.

Wrong Type of Backer Rod

Absorbent open-cell used in exterior wet conditions → failure risk.

Improper Depth

Too deep → excessive sealant

Too shallow → weak profileNot Cleaning Joint Before Installation

Debris prevents adhesion.

10. FAQs About Backer Rods

Q: Can I skip using a backer rod?

A: You can, but expect reduced sealant performance and premature failure.Q: Are backer rods reusable?

A: No, they are permanently embedded.Q: Do backer rods insulate?

A: Yes, they provide minor thermal insulation.Q: Can backer rods be used underwater?

A: Closed-cell types can be used with appropriate marine-grade sealants.

Conclusion

Backer rods are a crucial yet often overlooked element in modern sealing and joint systems. By controlling sealant depth, preventing three-sided adhesion, and ensuring proper joint geometry, they play a central role in creating long-lasting, flexible, and durable seals. Whether for concrete expansion joints, glazing, window installations, or log homes, understanding how to choose and install the right backer rod is essential for any construction professional.

-

-

Advanced Backer Rod Guidelines (Professional-Level)

1. Joint Preparation Guidelines

1.1 Cleaning Requirements

Before inserting any backer rod:

-

Remove loose debris using a wire brush or compressed air.

-

Clean with a solvent approved for your sealant (usually isopropyl alcohol).

-

Ensure the joint is dry, unless using a sealant formulated for damp surfaces.

-

If old sealant exists, cut it out fully—never seal over old material.

1.2 Surface Condition

Joint sides must be:

-

Sound (no crumbled concrete or splits)

-

Non-oily and grease-free

-

Even and parallel to ensure the backer rod stays in place

If surfaces are irregular, open-cell or bi-cellular rods are recommended due to higher flexibility.

2. Sizing Guidelines

Correct sizing is critical. Use the rules below:

2.1 Diameter Selection Rule

Choose a backer rod:

-

25% larger than the joint width for closed-cell

-

30–50% larger for open-cell

-

Ensure a compression fit so it stays firmly in place

2.2 Joint Depth-to-Width Ratios

Follow industry-standard ratios:

Joint Width Recommended Sealant Depth Rod Placement Depth ≤ ½ inch ¼ inch Rod at ¼ inch deep ½–1 inch ¼–½ inch Half the joint width ≥ 1 inch ½ inch Half the joint width Sealant depth is always less than width, except in shallow cosmetic joints.

3. Placement Guidelines

3.1 Tools for Installation

-

Backer rod rollers (best for long concrete joints)

-

Plastic or rubber paddles (to avoid puncturing)

-

Blunt putty knives

-

Push sticks or rods

Avoid sharp tools that can puncture closed-cell rods.

3.2 Insertion Technique

-

Push backer rod into the joint gently but firmly.

-

Maintain uniform depth along the entire joint.

-

Avoid stretching the rod—this reduces diameter and compromises fit.

Tip: If joints vary in width, use different rod diameters rather than forcing a single size.

3.3 Handling Corners and Angles

-

Cut rods at a 45° angle to prevent gaps in corner joints.

-

Never fold or crease the rod sharply, as this reduces performance.

4. Sealant Application Guidelines

4.1 Choosing the Right Sealant

Match sealant type to rod type:

Sealant Type Closed-Cell Rod Open-Cell Rod Bi-Cellular Rod Silicone ✔️ Best ✔️ Good ✔️ Excellent Polyurethane ✔️ Best ✔️ Good ✔️ Excellent Latex/Acrylic ✔️ Good ✔️ Good ✔️ Good Butyl ✔️ Good ❌ Avoid ✔️ OK Hybrid Sealants ✔️ Excellent ✔️ Excellent ✔️ Excellent Avoid using solvent-based sealants that attack polyethylene foam.

4.2 Sealant Application Angle

Hold the sealant gun at a 45° angle to ensure deep, uniform placement against joint sides.

4.3 Tooling

-

Tool the sealant within 5 minutes of application.

-

Create a smooth, concave finish.

-

Avoid over-tooling which thins the sealant.

5. Environmental Guidelines

5.1 Temperature Conditions

-

Ideal installation temperature: 5°C to 35°C (41°F to 95°F)

-

Closed-cell rods stiffen in cold weather; warm them slightly if needed.

5.2 Moisture Conditions

-

Avoid installing open-cell rods in areas exposed to standing water.

-

Ensure joint is fully dry for most sealants unless using moisture-cure formulations.

5.3 UV Exposure

Backer rods are not UV-resistant, so they must be fully covered by sealant.

6. Special Application Guidelines

6.1 Expansion Joints

-

Use closed-cell for all horizontal exterior concrete joints.

-

Ensure the sealant expansion capacity matches the expected joint movement.

-

Maintain cleanliness; expansion joints must move freely.

6.2 Window and Door Perimeter Joints

For fenestration (window/door frames):

-

Use open-cell or bi-cellular due to better compressibility.

-

Sealant depth should be ~⅜ inch for perimeter joints.

6.3 Glazing Systems

For structural silicone glazing:

-

Only use high-temperature bi-cellular rods approved by system engineers.

-

Maintain precise depth control—incorrect geometry may cause failure.

6.4 Log Homes

-

Use open-cell rods for chinking systems.

-

Insert loosely to allow seasonal log movement.

7. Safety Guidelines

7.1 Personal Protection

-

Wear gloves to prevent skin irritation.

-

Eye protection is recommended when cleaning joints.

7.2 Fire Considerations

Most backer rods are polyethylene-based and can melt or burn:

-

Keep away from open flames.

-

Never use heat guns to soften rods.

7.3 Chemical Safety

-

Avoid using with solvent-based sealants that degrade foam.

-

Check manufacturer compatibility charts.

8. Dos and Don’ts (Field Technician Checklist)

✔️ Do

-

Compress the rod by 25–50%.

-

Keep it clean and free of dust.

-

Maintain uniform depth throughout the joint.

-

Use correct tools to prevent puncture.

-

Match rod type to environmental conditions.

❌ Don’t

-

Never use too small of a rod.

-

Do not puncture closed-cell rods.

-

Do not stretch the rod.

-

Do not leave rod exposed (must be fully sealed).

-

Never install in freezing temperatures without proper precautions.

9. Troubleshooting Guidelines

Problem 1: Sealant Bubbles

Cause: Punctured closed-cell rack

Solution: Replace rod; use open-cell or bi-cellular where air escape is needed.Problem 2: Sealant Cracking

Cause: Too thick sealant or three-sided adhesion

Solution: Adjust depth; ensure rod acts as a bond breaker.Problem 3: Rod Pops Out

Cause: Rod is undersized or joint was not cleaned

Solution: Use larger diameter; clean surfaces.Problem 4: Sealant Not Adhering

Cause: Dirty joint walls or incompatible materials

Solution: Clean the surface and use the correct sealant type.

10. Quality Control Guidelines

Professional installers follow QC procedures:

10.1 Depth Measurement

Use depth gauges or marked tools.

10.2 Adhesion Testing

Perform sealant pull tests after curing.

10.3 Visual Inspection

Look for:

-

uniform width

-

smooth finish

-

complete coverage with no rod visible

-

no voids or bubbles

10.4 Documentation

Record:

-

rod type

-

rod size

-

sealant used

-

weather conditions

-

lot numbers

11. Storage and Handling Guidelines

11.1 Storage Conditions

-

Keep backer rods at room temperature.

-

Store out of direct sunlight.

-

Keep sealed in bags until use to prevent contamination.

11.2 Transport

Avoid crushing rods during transport—they may not rebound fully.

11.3 Shelf Life

Backer rods have no strict expiration date but should be kept dry and clean.

-

-