✅ Structural Moisture Barrier Coating | High-Performance PU Liquid Rubber

🧱 PART 1 — HUMAN STYLE CONTENT

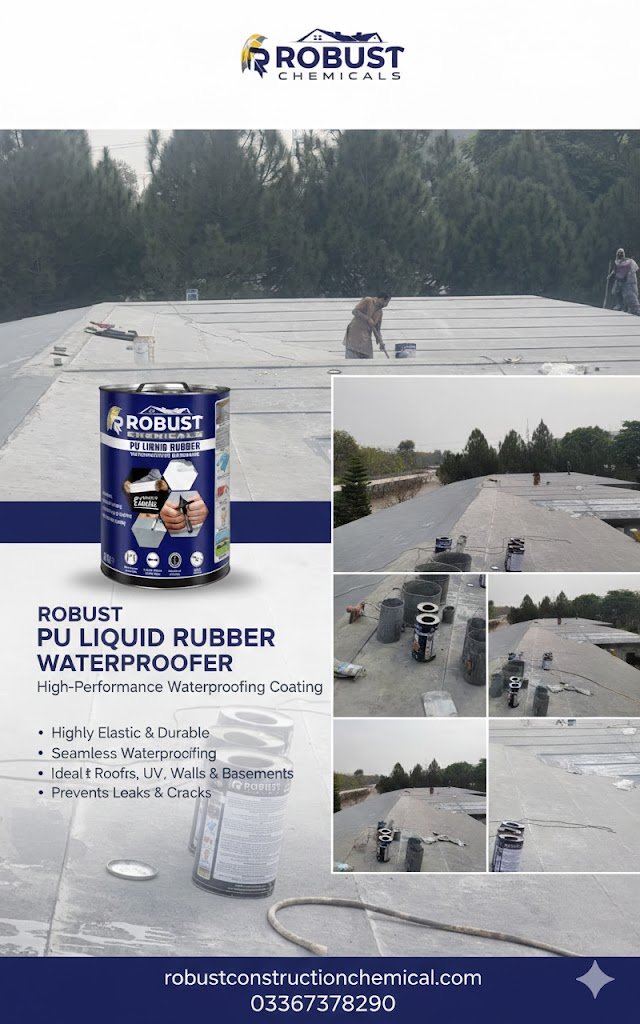

Structural Moisture Barrier Coating – High-Performance PU Liquid Rubber Waterproofing

Water problems in buildings usually don’t announce themselves loudly in the beginning. A small damp patch, a faint smell of moisture, maybe paint that starts bubbling near a corner. Most people ignore these early signs because they don’t look serious at first. Months later the same area turns into peeling plaster, rust stains, mold growth, and sometimes even structural weakness. This is exactly why moisture protection is not just a finishing step, it is part of the building’s long-term safety and value.

Many contractors today prefer liquid waterproof coatings because they adapt better to real site conditions. Every slab, wall, joint, and corner behaves differently. Concrete is rarely perfect. Surfaces have hairline cracks, pores, uneven textures, and small movement that continues even after construction is completed. A flexible coating that flows into these imperfections performs better than rigid materials that expect ideal surfaces. PU liquid rubber falls into this category because it spreads easily, bonds strongly, and cures into a continuous rubbery layer.

One thing that surprises new users is how seamless the coating becomes after curing. There are no sheet overlaps, no welded joints, no mechanical fixing holes. It simply becomes one skin over the surface. When you look closely at areas like drain outlets, pipe penetrations, or corner edges, you can clearly see how the coating wraps around shapes naturally instead of forcing straight lines like traditional membranes. That detail alone reduces many future leakage complaints.

Flexibility is another major reason people move toward polyurethane rubber systems. Buildings are not static. Temperature changes during day and night cause expansion and contraction. Heavy rain cools surfaces suddenly. Sun heats roofs aggressively. Minor vibrations come from traffic, machinery, or wind loads. Rigid coatings slowly crack under these movements. Rubber based coatings stretch and recover instead of breaking. Over time this behavior keeps water out instead of letting it find tiny entry points.

Application itself is usually simple. Rollers, brushes, or spray equipment are enough for most jobs. Workers do not need complex machines or special welding skills. On renovation projects this saves a lot of time because surfaces can be cleaned and coated without tearing up existing layers unnecessarily. Many site managers appreciate this because it reduces noise, dust, and project delays.

Surface preparation still deserves attention. No coating can perform well if applied on oily, dusty, or loose surfaces. Cleaning, light grinding where needed, filling visible cracks, and allowing proper drying make a big difference in final performance. Skipping preparation often causes bonding problems later, which people sometimes blame on the product instead of workmanship.

Once cured, the coating feels tough yet elastic. You can press it slightly and feel its flexibility. It bridges small cracks easily and seals tiny surface pores that would otherwise allow slow moisture seepage. This becomes very useful on roofs, balconies, parking decks, wet areas, basements, and service rooms where water exposure is frequent and unpredictable.

Chemical exposure is another hidden challenge in urban buildings. Dust carries salts. Rainwater mixes with pollutants. Cleaning chemicals are used regularly in commercial spaces. Mild oils and industrial residues also reach floors and slabs. A quality PU liquid rubber coating resists gradual chemical attack much better than normal paints or low grade waterproof layers, helping maintain surface integrity for longer periods.

Maintenance is usually simple. If mechanical damage occurs due to sharp tools or heavy impact, the damaged area can be cleaned and recoated locally. No need to replace entire membranes or remove large sections. This saves cost and avoids unnecessary downtime in operational buildings.

In terms of comfort, controlling moisture improves indoor conditions. Damp environments encourage mold growth, unpleasant odors, and surface discoloration. Dry structures feel healthier, cleaner, and easier to maintain. This benefit is often underestimated during construction but becomes very noticeable over years of building use.

Outdoor exposure naturally tests any coating. Sunlight, temperature swings, rain cycles, and dust accumulation slowly degrade materials. When protected with compatible top layers, PU liquid rubber holds elasticity and adhesion much better than many conventional systems. Roofs especially benefit from this resilience when maintained properly.

From a cost perspective, long-term savings matter more than initial material price. Reduced leakage repairs, fewer interior damages, and extended surface life gradually recover the investment. Facility owners usually realize this advantage after a few years of operation.

One practical advantage many installers mention is detailing simplicity. Around drains, pipe sleeves, anchor bolts, and irregular edges, liquid coating flows naturally and forms a continuous seal. Sheet membranes often struggle in these areas and rely heavily on workmanship accuracy.

Environmental expectations are also improving. Modern formulations aim for controlled odor and safer handling conditions while maintaining performance. This makes site work more comfortable for workers and occupants during refurbishment projects.

As cities grow and weather patterns become unpredictable, moisture protection becomes even more important. Heavy rainfall, sudden temperature shifts, and dense construction all increase water related risks. Reliable coatings play a major role in protecting investments and maintaining building safety.

Choosing the right system is not only about product quality but also correct installation, proper surface preparation, compatible protective layers, and reasonable maintenance planning. When these factors align, PU liquid rubber systems deliver dependable service for many years.

✅ Structural Moisture Barrier Coating | High-Performance PU Liquid Rubber

🧱 PART 1 — HUMAN STYLE CONTENT

Water problems in buildings usually don’t announce themselves loudly in the beginning. A small damp patch, a faint smell of moisture, maybe paint that starts bubbling near a corner. Most people ignore these early signs because they don’t look serious at first. Months later the same area turns into peeling plaster, rust stains, mold growth, and sometimes even structural weakness. This is exactly why moisture protection is not just a finishing step, it is part of the building’s long-term safety and value.

Many contractors today prefer liquid waterproof coatings because they adapt better to real site conditions. Every slab, wall, joint, and corner behaves differently. Concrete is rarely perfect. Surfaces have hairline cracks, pores, uneven textures, and small movement that continues even after construction is completed. A flexible coating that flows into these imperfections performs better than rigid materials that expect ideal surfaces. PU liquid rubber falls into this category because it spreads easily, bonds strongly, and cures into a continuous rubbery layer.

One thing that surprises new users is how seamless the coating becomes after curing. There are no sheet overlaps, no welded joints, no mechanical fixing holes. It simply becomes one skin over the surface. When you look closely at areas like drain outlets, pipe penetrations, or corner edges, you can clearly see how the coating wraps around shapes naturally instead of forcing straight lines like traditional membranes. That detail alone reduces many future leakage complaints.

Flexibility is another major reason people move toward polyurethane rubber systems. Buildings are not static. Temperature changes during day and night cause expansion and contraction. Heavy rain cools surfaces suddenly. Sun heats roofs aggressively. Minor vibrations come from traffic, machinery, or wind loads. Rigid coatings slowly crack under these movements. Rubber based coatings stretch and recover instead of breaking. Over time this behavior keeps water out instead of letting it find tiny entry points.

Application itself is usually simple. Rollers, brushes, or spray equipment are enough for most jobs. Workers do not need complex machines or special welding skills. On renovation projects this saves a lot of time because surfaces can be cleaned and coated without tearing up existing layers unnecessarily. Many site managers appreciate this because it reduces noise, dust, and project delays.

Surface preparation still deserves attention. No coating can perform well if applied on oily, dusty, or loose surfaces. Cleaning, light grinding where needed, filling visible cracks, and allowing proper drying make a big difference in final performance. Skipping preparation often causes bonding problems later, which people sometimes blame on the product instead of workmanship.

Once cured, the coating feels tough yet elastic. You can press it slightly and feel its flexibility. It bridges small cracks easily and seals tiny surface pores that would otherwise allow slow moisture seepage. This becomes very useful on roofs, balconies, parking decks, wet areas, basements, and service rooms where water exposure is frequent and unpredictable.

Chemical exposure is another hidden challenge in urban buildings. Dust carries salts. Rainwater mixes with pollutants. Cleaning chemicals are used regularly in commercial spaces. Mild oils and industrial residues also reach floors and slabs. A quality PU liquid rubber coating resists gradual chemical attack much better than normal paints or low grade waterproof layers, helping maintain surface integrity for longer periods.

Maintenance is usually simple. If mechanical damage occurs due to sharp tools or heavy impact, the damaged area can be cleaned and recoated locally. No need to replace entire membranes or remove large sections. This saves cost and avoids unnecessary downtime in operational buildings.

In terms of comfort, controlling moisture improves indoor conditions. Damp environments encourage mold growth, unpleasant odors, and surface discoloration. Dry structures feel healthier, cleaner, and easier to maintain. This benefit is often underestimated during construction but becomes very noticeable over years of building use.

Outdoor exposure naturally tests any coating. Sunlight, temperature swings, rain cycles, and dust accumulation slowly degrade materials. When protected with compatible top layers, PU liquid rubber holds elasticity and adhesion much better than many conventional systems. Roofs especially benefit from this resilience when maintained properly.

From a cost perspective, long-term savings matter more than initial material price. Reduced leakage repairs, fewer interior damages, and extended surface life gradually recover the investment. Facility owners usually realize this advantage after a few years of operation.

One practical advantage many installers mention is detailing simplicity. Around drains, pipe sleeves, anchor bolts, and irregular edges, liquid coating flows naturally and forms a continuous seal. Sheet membranes often struggle in these areas and rely heavily on workmanship accuracy.

Environmental expectations are also improving. Modern formulations aim for controlled odor and safer handling conditions while maintaining performance. This makes site work more comfortable for workers and occupants during refurbishment projects.

As cities grow and weather patterns become unpredictable, moisture protection becomes even more important. Heavy rainfall, sudden temperature shifts, and dense construction all increase water related risks. Reliable coatings play a major role in protecting investments and maintaining building safety.

Choosing the right system is not only about product quality but also correct installation, proper surface preparation, compatible protective layers, and reasonable maintenance planning. When these factors align, PU liquid rubber systems deliver dependable service for many years.

✅ Structural Moisture Barrier Coating | High-Performance PU Liquid Rubber

🧱 PART 1 — HUMAN STYLE CONTENT

Water problems in buildings usually don’t announce themselves loudly in the beginning. A small damp patch, a faint smell of moisture, maybe paint that starts bubbling near a corner. Most people ignore these early signs because they don’t look serious at first. Months later the same area turns into peeling plaster, rust stains, mold growth, and sometimes even structural weakness. This is exactly why moisture protection is not just a finishing step, it is part of the building’s long-term safety and value.

Many contractors today prefer liquid waterproof coatings because they adapt better to real site conditions. Every slab, wall, joint, and corner behaves differently. Concrete is rarely perfect. Surfaces have hairline cracks, pores, uneven textures, and small movement that continues even after construction is completed. A flexible coating that flows into these imperfections performs better than rigid materials that expect ideal surfaces. PU liquid rubber falls into this category because it spreads easily, bonds strongly, and cures into a continuous rubbery layer.

One thing that surprises new users is how seamless the coating becomes after curing. There are no sheet overlaps, no welded joints, no mechanical fixing holes. It simply becomes one skin over the surface. When you look closely at areas like drain outlets, pipe penetrations, or corner edges, you can clearly see how the coating wraps around shapes naturally instead of forcing straight lines like traditional membranes. That detail alone reduces many future leakage complaints.

Flexibility is another major reason people move toward polyurethane rubber systems. Buildings are not static. Temperature changes during day and night cause expansion and contraction. Heavy rain cools surfaces suddenly. Sun heats roofs aggressively. Minor vibrations come from traffic, machinery, or wind loads. Rigid coatings slowly crack under these movements. Rubber based coatings stretch and recover instead of breaking. Over time this behavior keeps water out instead of letting it find tiny entry points.

Application itself is usually simple. Rollers, brushes, or spray equipment are enough for most jobs. Workers do not need complex machines or special welding skills. On renovation projects this saves a lot of time because surfaces can be cleaned and coated without tearing up existing layers unnecessarily. Many site managers appreciate this because it reduces noise, dust, and project delays.

Surface preparation still deserves attention. No coating can perform well if applied on oily, dusty, or loose surfaces. Cleaning, light grinding where needed, filling visible cracks, and allowing proper drying make a big difference in final performance. Skipping preparation often causes bonding problems later, which people sometimes blame on the product instead of workmanship.

Once cured, the coating feels tough yet elastic. You can press it slightly and feel its flexibility. It bridges small cracks easily and seals tiny surface pores that would otherwise allow slow moisture seepage. This becomes very useful on roofs, balconies, parking decks, wet areas, basements, and service rooms where water exposure is frequent and unpredictable.

Chemical exposure is another hidden challenge in urban buildings. Dust carries salts. Rainwater mixes with pollutants. Cleaning chemicals are used regularly in commercial spaces. Mild oils and industrial residues also reach floors and slabs. A quality PU liquid rubber coating resists gradual chemical attack much better than normal paints or low grade waterproof layers, helping maintain surface integrity for longer periods.

Maintenance is usually simple. If mechanical damage occurs due to sharp tools or heavy impact, the damaged area can be cleaned and recoated locally. No need to replace entire membranes or remove large sections. This saves cost and avoids unnecessary downtime in operational buildings.

In terms of comfort, controlling moisture improves indoor conditions. Damp environments encourage mold growth, unpleasant odors, and surface discoloration. Dry structures feel healthier, cleaner, and easier to maintain. This benefit is often underestimated during construction but becomes very noticeable over years of building use.

Outdoor exposure naturally tests any coating. Sunlight, temperature swings, rain cycles, and dust accumulation slowly degrade materials. When protected with compatible top layers, PU liquid rubber holds elasticity and adhesion much better than many conventional systems. Roofs especially benefit from this resilience when maintained properly.

From a cost perspective, long-term savings matter more than initial material price. Reduced leakage repairs, fewer interior damages, and extended surface life gradually recover the investment. Facility owners usually realize this advantage after a few years of operation.

One practical advantage many installers mention is detailing simplicity. Around drains, pipe sleeves, anchor bolts, and irregular edges, liquid coating flows naturally and forms a continuous seal. Sheet membranes often struggle in these areas and rely heavily on workmanship accuracy.

Environmental expectations are also improving. Modern formulations aim for controlled odor and safer handling conditions while maintaining performance. This makes site work more comfortable for workers and occupants during refurbishment projects.

As cities grow and weather patterns become unpredictable, moisture protection becomes even more important. Heavy rainfall, sudden temperature shifts, and dense construction all increase water related risks. Reliable coatings play a major role in protecting investments and maintaining building safety.

Choosing the right system is not only about product quality but also correct installation, proper surface preparation, compatible protective layers, and reasonable maintenance planning. When these factors align, PU liquid rubber systems deliver dependable service for many years.

moisturemoisturemoisturemoisturemoisturemoisturemoisturemoisturemoisturemoisturemoisturemoisturemoisturemoisturemoisturemoisturemoisturemoisturemoisturemoisturemoisturemoisturemoisture