Industrial Waterproofing Chemicals & Epoxy Flooring Systems | Heavy-Duty Floor Protection Solutions

Introduction to Industrial Waterproofing Chemicals

Industrial environments such as factories, warehouses, power plants, pharmaceutical units, food processing facilities, and chemical plants require advanced waterproofing and protective flooring systems. Constant exposure to moisture, chemicals, oils, abrasion, and heavy mechanical loads can severely damage concrete surfaces if not properly protected. Industrial waterproofing chemicals are specially engineered formulations designed to protect structures from water ingress, chemical attack, and long-term deterioration.

Among these solutions, epoxy flooring systems have emerged as one of the most reliable and widely used industrial waterproofing and surface protection technologies. Epoxy flooring not only provides waterproofing but also enhances mechanical strength, chemical resistance, hygiene, and aesthetic appeal of industrial floors.

Understanding Epoxy Flooring in Industrial Waterproofing

Epoxy flooring is a high-performance coating system made from epoxy resins and hardeners that chemically react to form a rigid, durable, and impermeable surface. When applied over concrete, epoxy flooring creates a seamless waterproof membrane that prevents water penetration, resists chemical spills, and withstands heavy industrial traffic.

Industrial epoxy flooring is considered both a waterproofing chemical system and a protective floor coating, making it a dual-purpose solution for demanding environments.

Why Waterproofing Is Critical for Industrial Floors

Concrete, although strong in compression, is inherently porous. In industrial settings, water penetration through floors can cause:

-

Corrosion of steel reinforcement

-

Chemical degradation of concrete

-

Cracking, dusting, and surface delamination

-

Growth of bacteria and mold

-

Reduced service life of floors

Industrial waterproofing chemicals, especially epoxy flooring systems, seal concrete pores and provide a continuous barrier against moisture and aggressive substances.

Key Benefits of Epoxy Flooring for Industrial Waterproofing

1. Superior Waterproofing Performance

Epoxy flooring forms a non-porous, impermeable layer that completely blocks water penetration. This makes it ideal for wet processing areas, basements, and water-exposed industrial zones.

2. Exceptional Chemical Resistance

Epoxy systems resist acids, alkalis, oils, solvents, fuels, and industrial chemicals. This property is crucial in chemical plants, laboratories, and manufacturing facilities.

3. High Mechanical Strength

Epoxy flooring significantly improves compressive strength, abrasion resistance, and impact resistance of concrete floors, making them suitable for forklifts, heavy machinery, and continuous traffic.

4. Seamless and Hygienic Surface

The joint-free surface prevents dirt accumulation, bacterial growth, and contamination, making epoxy flooring ideal for food, pharmaceutical, and healthcare industries.

5. Long Service Life

With proper installation and maintenance, industrial epoxy flooring can last 10–20 years, reducing repair and replacement costs.

Types of Industrial Epoxy Flooring Systems

Self-Leveling Epoxy Flooring

Self-leveling epoxy creates a smooth, glossy, and highly durable surface. It is widely used in manufacturing plants, clean rooms, and warehouses.

Epoxy Mortar Flooring

This heavy-duty system consists of epoxy resin combined with graded aggregates. It offers extreme strength and is suitable for areas exposed to heavy impact and chemical attack.

Epoxy Quartz Flooring

Epoxy quartz systems incorporate colored quartz aggregates, providing decorative appeal along with excellent slip resistance and waterproofing.

Anti-Static Epoxy Flooring

Used in electronic manufacturing and data centers, anti-static epoxy flooring prevents static electricity build-up while providing waterproof protection.

Industrial Waterproofing Chemicals Used with Epoxy Flooring

Epoxy flooring is often used in combination with other industrial waterproofing chemicals to ensure complete system performance:

-

Epoxy primers for concrete sealing

-

Moisture barrier coatings

-

Crack injection epoxies

-

Epoxy joint sealants

-

Chemical-resistant epoxy topcoats

These chemicals work together to form a comprehensive waterproofing and protection system.

Applications of Epoxy Flooring in Industrial Sectors

Manufacturing Plants

Protects floors from oils, chemicals, vibration, and heavy equipment loads.

Warehouses & Logistics Centers

Provides dust-free, abrasion-resistant, and waterproof surfaces for forklifts and pallet traffic.

Pharmaceutical & Food Processing Units

Ensures hygienic, easy-to-clean, and contamination-free flooring.

Chemical & Petrochemical Industries

Resists aggressive chemicals, solvents, and moisture exposure.

Basements & Utility Areas

Acts as a waterproof barrier against groundwater and moisture seepage.

Surface Preparation – The Key to Epoxy Waterproofing Success

Proper surface preparation is critical for the performance of epoxy flooring systems. Steps include:

-

Mechanical grinding or shot blasting

-

Removal of oil, grease, and contaminants

-

Repair of cracks and voids using epoxy fillers

-

Moisture testing of concrete

-

Application of epoxy primer

A well-prepared substrate ensures strong adhesion and long-term waterproofing performance.

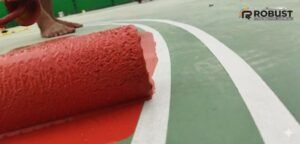

Installation Process of Industrial Epoxy Flooring

-

Concrete surface inspection and testing

-

Surface preparation and cleaning

-

Application of epoxy primer

-

Application of epoxy base coat

-

Broadcasting of aggregates (if required)

-

Application of epoxy topcoat or seal coat

Each step must be performed under controlled conditions to achieve optimal waterproofing results.

Epoxy Flooring vs Traditional Waterproofing Methods

Compared to traditional cementitious or bituminous systems, epoxy flooring offers:

-

Better chemical resistance

-

Higher mechanical strength

-

Seamless finish

-

Faster curing time

-

Longer durability

This makes epoxy flooring a preferred choice for industrial waterproofing projects.

Maintenance and Durability

Industrial epoxy flooring requires minimal maintenance. Regular cleaning, prompt removal of chemical spills, and periodic inspection can significantly extend its service life. Minor damages can be repaired locally without replacing the entire floor system.

Environmental and Safety Advantages

Modern epoxy waterproofing chemicals are available in low-VOC and solvent-free formulations, making them environmentally friendly and safe for indoor use. Anti-slip and fire-resistant properties further enhance workplace safety.

Choosing the Right Epoxy Waterproofing System

Selection depends on:

-

Type of industry

-

Chemical exposure level

-

Traffic load

-

Moisture conditions

-

Hygiene requirements

Professional consultation ensures the right epoxy flooring system is chosen for maximum performance.

Industrial Waterproofing Chemicals & Epoxy Flooring Systems | Heavy-Duty Floor Protection Solutions

Introduction to Industrial Waterproofing Chemicals

Industrial environments such as factories, warehouses, power plants, pharmaceutical units, food processing facilities, and chemical plants require advanced waterproofing and protective flooring systems. Constant exposure to moisture, chemicals, oils, abrasion, and heavy mechanical loads can severely damage concrete surfaces if not properly protected. Industrial waterproofing chemicals are specially engineered formulations designed to protect structures from water ingress, chemical attack, and long-term deterioration.

Among these solutions, epoxy flooring systems have emerged as one of the most reliable and widely used industrial waterproofing and surface protection technologies. Epoxy flooring not only provides waterproofing but also enhances mechanical strength, chemical resistance, hygiene, and aesthetic appeal of industrial floors.

Understanding Epoxy Flooring in Industrial Waterproofing

Epoxy flooring is a high-performance coating system made from epoxy resins and hardeners that chemically react to form a rigid, durable, and impermeable surface. When applied over concrete, epoxy flooring creates a seamless waterproof membrane that prevents water penetration, resists chemical spills, and withstands heavy industrial traffic.

Industrial epoxy flooring is considered both a waterproofing chemical system and a protective floor coating, making it a dual-purpose solution for demanding environments.

Why Waterproofing Is Critical for Industrial Floors

Concrete, although strong in compression, is inherently porous. In industrial settings, water penetration through floors can cause:

-

Corrosion of steel reinforcement

-

Chemical degradation of concrete

-

Cracking, dusting, and surface delamination

-

Growth of bacteria and mold

-

Reduced service life of floors

Industrial waterproofing chemicals, especially epoxy flooring systems, seal concrete pores and provide a continuous barrier against moisture and aggressive substances.

Key Benefits of Epoxy Flooring for Industrial Waterproofing

1. Superior Waterproofing Performance

Epoxy flooring forms a non-porous, impermeable layer that completely blocks water penetration. This makes it ideal for wet processing areas, basements, and water-exposed industrial zones.

2. Exceptional Chemical Resistance

Epoxy systems resist acids, alkalis, oils, solvents, fuels, and industrial chemicals. This property is crucial in chemical plants, laboratories, and manufacturing facilities.

3. High Mechanical Strength

Epoxy flooring significantly improves compressive strength, abrasion resistance, and impact resistance of concrete floors, making them suitable for forklifts, heavy machinery, and continuous traffic.

4. Seamless and Hygienic Surface

The joint-free surface prevents dirt accumulation, bacterial growth, and contamination, making epoxy flooring ideal for food, pharmaceutical, and healthcare industries.

5. Long Service Life

With proper installation and maintenance, industrial epoxy flooring can last 10–20 years, reducing repair and replacement costs.

Types of Industrial Epoxy Flooring Systems

Self-Leveling Epoxy Flooring

Self-leveling epoxy creates a smooth, glossy, and highly durable surface. It is widely used in manufacturing plants, clean rooms, and warehouses.

Epoxy Mortar Flooring

This heavy-duty system consists of epoxy resin combined with graded aggregates. It offers extreme strength and is suitable for areas exposed to heavy impact and chemical attack.

Epoxy Quartz Flooring

Epoxy quartz systems incorporate colored quartz aggregates, providing decorative appeal along with excellent slip resistance and waterproofing.

Anti-Static Epoxy Flooring

Used in electronic manufacturing and data centers, anti-static epoxy flooring prevents static electricity build-up while providing waterproof protection.

Industrial Waterproofing Chemicals Used with Epoxy Flooring

Epoxy flooring is often used in combination with other industrial waterproofing chemicals to ensure complete system performance:

-

Epoxy primers for concrete sealing

-

Moisture barrier coatings

-

Crack injection epoxies

-

Epoxy joint sealants

-

Chemical-resistant epoxy topcoats

These chemicals work together to form a comprehensive waterproofing and protection system.

Applications of Epoxy Flooring in Industrial Sectors

Manufacturing Plants

Protects floors from oils, chemicals, vibration, and heavy equipment loads.

Warehouses & Logistics Centers

Provides dust-free, abrasion-resistant, and waterproof surfaces for forklifts and pallet traffic.

Pharmaceutical & Food Processing Units

Ensures hygienic, easy-to-clean, and contamination-free flooring.

Chemical & Petrochemical Industries

Resists aggressive chemicals, solvents, and moisture exposure.

Basements & Utility Areas

Acts as a waterproof barrier against groundwater and moisture seepage.

Surface Preparation – The Key to Epoxy Waterproofing Success

Proper surface preparation is critical for the performance of epoxy flooring systems. Steps include:

-

Mechanical grinding or shot blasting

-

Removal of oil, grease, and contaminants

-

Repair of cracks and voids using epoxy fillers

-

Moisture testing of concrete

-

Application of epoxy primer

A well-prepared substrate ensures strong adhesion and long-term waterproofing performance.

Installation Process of Industrial Epoxy Flooring

-

Concrete surface inspection and testing

-

Surface preparation and cleaning

-

Application of epoxy primer

-

Application of epoxy base coat

-

Broadcasting of aggregates (if required)

-

Application of epoxy topcoat or seal coat

Each step must be performed under controlled conditions to achieve optimal waterproofing results.

Epoxy Flooring vs Traditional Waterproofing Methods

Compared to traditional cementitious or bituminous systems, epoxy flooring offers:

-

Better chemical resistance

-

Higher mechanical strength

-

Seamless finish

-

Faster curing time

-

Longer durability

This makes epoxy flooring a preferred choice for industrial waterproofing projects.

Maintenance and Durability

Industrial epoxy flooring requires minimal maintenance. Regular cleaning, prompt removal of chemical spills, and periodic inspection can significantly extend its service life. Minor damages can be repaired locally without replacing the entire floor system.

Environmental and Safety Advantages

Modern epoxy waterproofing chemicals are available in low-VOC and solvent-free formulations, making them environmentally friendly and safe for indoor use. Anti-slip and fire-resistant properties further enhance workplace safety.

Choosing the Right Epoxy Waterproofing System

Selection depends on:

-

Type of industry

-

Chemical exposure level

-

Traffic load

-

Moisture conditions

-

Hygiene requirements

Professional consultation ensures the right epoxy flooring system is chosen for maximum performance.

Industrial Waterproofing Chemicals & Epoxy Flooring Systems | Heavy-Duty Floor Protection Solutions

Introduction to Industrial Waterproofing Chemicals

Industrial environments such as factories, warehouses, power plants, pharmaceutical units, food processing facilities, and chemical plants require advanced waterproofing and protective flooring systems. Constant exposure to moisture, chemicals, oils, abrasion, and heavy mechanical loads can severely damage concrete surfaces if not properly protected. Industrial waterproofing chemicals are specially engineered formulations designed to protect structures from water ingress, chemical attack, and long-term deterioration.

Among these solutions, epoxy flooring systems have emerged as one of the most reliable and widely used industrial waterproofing and surface protection technologies. Epoxy flooring not only provides waterproofing but also enhances mechanical strength, chemical resistance, hygiene, and aesthetic appeal of industrial floors.

Understanding Epoxy Flooring in Industrial Waterproofing

Epoxy flooring is a high-performance coating system made from epoxy resins and hardeners that chemically react to form a rigid, durable, and impermeable surface. When applied over concrete, epoxy flooring creates a seamless waterproof membrane that prevents water penetration, resists chemical spills, and withstands heavy industrial traffic.

Industrial epoxy flooring is considered both a waterproofing chemical system and a protective floor coating, making it a dual-purpose solution for demanding environments.

Why Waterproofing Is Critical for Industrial Floors

Concrete, although strong in compression, is inherently porous. In industrial settings, water penetration through floors can cause:

-

Corrosion of steel reinforcement

-

Chemical degradation of concrete

-

Cracking, dusting, and surface delamination

-

Growth of bacteria and mold

-

Reduced service life of floors

Industrial waterproofing chemicals, especially epoxy flooring systems, seal concrete pores and provide a continuous barrier against moisture and aggressive substances.

Key Benefits of Epoxy Flooring for Industrial Waterproofing

1. Superior Waterproofing Performance

Epoxy flooring forms a non-porous, impermeable layer that completely blocks water penetration. This makes it ideal for wet processing areas, basements, and water-exposed industrial zones.

2. Exceptional Chemical Resistance

Epoxy systems resist acids, alkalis, oils, solvents, fuels, and industrial chemicals. This property is crucial in chemical plants, laboratories, and manufacturing facilities.

3. High Mechanical Strength

Epoxy flooring significantly improves compressive strength, abrasion resistance, and impact resistance of concrete floors, making them suitable for forklifts, heavy machinery, and continuous traffic.

4. Seamless and Hygienic Surface

The joint-free surface prevents dirt accumulation, bacterial growth, and contamination, making epoxy flooring ideal for food, pharmaceutical, and healthcare industries.

5. Long Service Life

With proper installation and maintenance, industrial epoxy flooring can last 10–20 years, reducing repair and replacement costs.

Types of Industrial Epoxy Flooring Systems

Self-Leveling Epoxy Flooring

Self-leveling epoxy creates a smooth, glossy, and highly durable surface. It is widely used in manufacturing plants, clean rooms, and warehouses.

Epoxy Mortar Flooring

This heavy-duty system consists of epoxy resin combined with graded aggregates. It offers extreme strength and is suitable for areas exposed to heavy impact and chemical attack.

Epoxy Quartz Flooring

Epoxy quartz systems incorporate colored quartz aggregates, providing decorative appeal along with excellent slip resistance and waterproofing.

Anti-Static Epoxy Flooring

Used in electronic manufacturing and data centers, anti-static epoxy flooring prevents static electricity build-up while providing waterproof protection.

Industrial Waterproofing Chemicals Used with Epoxy Flooring

Epoxy flooring is often used in combination with other industrial waterproofing chemicals to ensure complete system performance:

-

Epoxy primers for concrete sealing

-

Moisture barrier coatings

-

Crack injection epoxies

-

Epoxy joint sealants

-

Chemical-resistant epoxy topcoats

These chemicals work together to form a comprehensive waterproofing and protection system.

Applications of Epoxy Flooring in Industrial Sectors

Manufacturing Plants

Protects floors from oils, chemicals, vibration, and heavy equipment loads.

Warehouses & Logistics Centers

Provides dust-free, abrasion-resistant, and waterproof surfaces for forklifts and pallet traffic.

Pharmaceutical & Food Processing Units

Ensures hygienic, easy-to-clean, and contamination-free flooring.

Chemical & Petrochemical Industries

Resists aggressive chemicals, solvents, and moisture exposure.

Basements & Utility Areas

Acts as a waterproof barrier against groundwater and moisture seepage.

Surface Preparation – The Key to Epoxy Waterproofing Success

Proper surface preparation is critical for the performance of epoxy flooring systems. Steps include:

-

Mechanical grinding or shot blasting

-

Removal of oil, grease, and contaminants

-

Repair of cracks and voids using epoxy fillers

-

Moisture testing of concrete

-

Application of epoxy primer

A well-prepared substrate ensures strong adhesion and long-term waterproofing performance.

Installation Process of Industrial Epoxy Flooring

-

Concrete surface inspection and testing

-

Surface preparation and cleaning

-

Application of epoxy primer

-

Application of epoxy base coat

-

Broadcasting of aggregates (if required)

-

Application of epoxy topcoat or seal coat

Each step must be performed under controlled conditions to achieve optimal waterproofing results.

Epoxy Flooring vs Traditional Waterproofing Methods

Compared to traditional cementitious or bituminous systems, epoxy flooring offers:

-

Better chemical resistance

-

Higher mechanical strength

-

Seamless finish

-

Faster curing time

-

Longer durability

This makes epoxy flooring a preferred choice for industrial waterproofing projects.

Maintenance and Durability

Industrial epoxy flooring requires minimal maintenance. Regular cleaning, prompt removal of chemical spills, and periodic inspection can significantly extend its service life. Minor damages can be repaired locally without replacing the entire floor system.

Environmental and Safety Advantages

Modern epoxy waterproofing chemicals are available in low-VOC and solvent-free formulations, making them environmentally friendly and safe for indoor use. Anti-slip and fire-resistant properties further enhance workplace safety.

Choosing the Right Epoxy Waterproofing System

Selection depends on:

-

Type of industry

-

Chemical exposure level

-

Traffic load

-

Moisture conditions

-

Hygiene requirements

Professional consultation ensures the right epoxy flooring system is chosen for maximum performance.