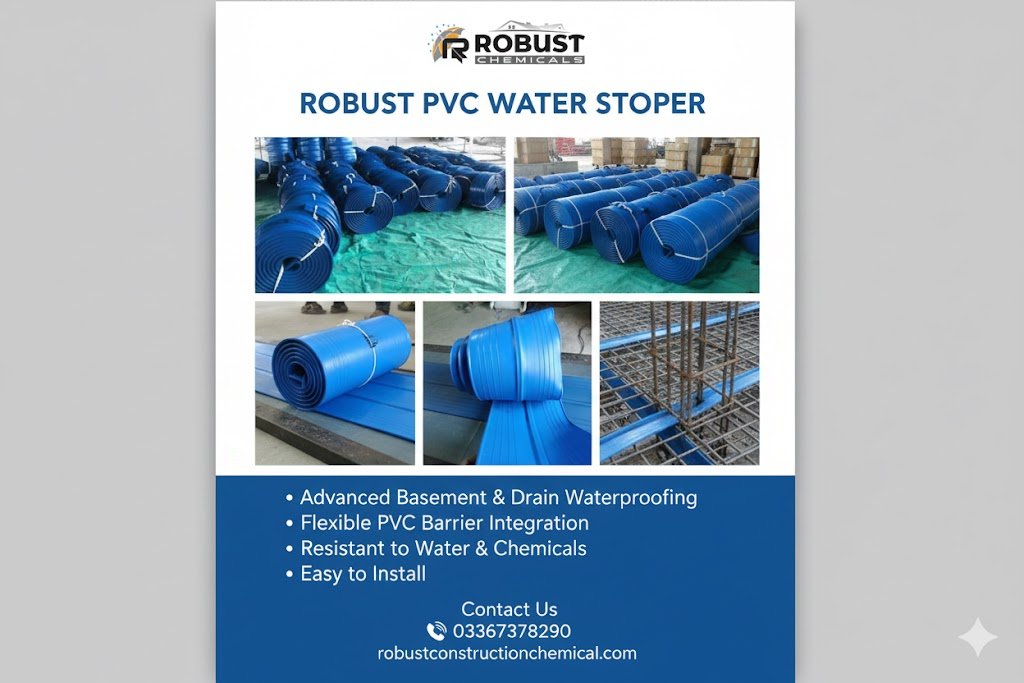

Foundation & Basement Joint Sealing | High-Load PVC Water Stopper System

Foundation & basement joint sealing is one of the most critical parts of structural waterproofing

because underground areas are always exposed to soil moisture and water pressure.

High-Load PVC Water Stopper System is specially designed to block water paths

and protect construction joints from leakage and long-term damage.

In modern concrete construction joints are unavoidable

and without proper joint sealing water can easily enter the structure.

PVC water stopper works as a physical barrier inside concrete joints

that prevents water movement even under high hydrostatic pressure.

Foundation slabs and basement walls are highly sensitive to seepage

so professional joint protection is essential for structural safety.

High-load PVC water stoppers are manufactured from flexible yet strong PVC material

that can absorb movement while maintaining complete watertight sealing.

During concrete pouring the water stopper becomes an integral part of the structure

ensuring permanent protection throughout the life of the building.

Basement leakage can lead to corrosion of steel reinforcement

which ultimately weakens the entire concrete structure.

Using PVC water stopper at joints prevents this problem

and increases the durability of foundations and retaining walls.

In areas with high groundwater levels joint protection becomes even more important

because water pressure continuously pushes against the concrete joints.

PVC water stopper creates a continuous sealing line

that blocks seepage paths and prevents water migration.

This system is widely used in residential basements commercial buildings

and large civil engineering structures for reliable waterproofing.

High-load PVC water stopper is ideal for expansion joints

where thermal movement and structural shifts can occur.

Its flexible design allows controlled movement

without breaking the waterproof seal at the joint.

In foundation systems water stopper profiles are placed at critical joints

such as slab to wall joints and wall to wall joints.

These joints are the most common points of leakage

so sealing them correctly ensures complete basement protection.

PVC water stopper is resistant to chemicals present in soil

which protects it from deterioration over long periods of time.

It also resists bacterial growth and does not rot

making it perfect for underground construction environments.

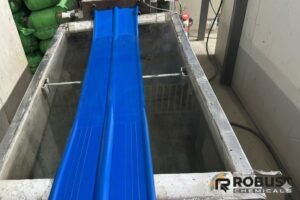

Proper installation of water stopper during concrete casting

is essential to achieve full waterproofing performance.

The profile must be fixed firmly in the center of the joint

so that it remains embedded properly after concrete placement.

Skilled workmanship ensures that the water stopper is not displaced

during vibration and concrete compaction.

Once embedded the water stopper becomes locked inside the joint

creating a permanent waterproof barrier.

High-load water stopper profiles are available in different shapes

to suit various joint designs and structural requirements.

Center bulb profiles are used for expansion joints

while flat profiles are used for construction joints.

Each profile type is designed to manage specific movement patterns

and water pressure conditions in concrete structures.

Foundation waterproofing systems are incomplete without joint protection

because membranes alone cannot seal dynamic concrete joints.

PVC water stopper complements surface waterproofing systems

by providing internal joint sealing protection.

When used together they form a complete waterproofing solution

that protects structures from both surface and internal water ingress.

Basement waterproofing failures often occur due to neglected joint sealing

which results in costly repair work after construction.

Installing PVC water stopper during construction prevents such future expenses

and ensures long-term waterproof performance.

High-load PVC water stoppers are tested for tensile strength and flexibility

to perform under heavy structural loads and movement.

They maintain their shape even under high compression

which is essential in deep foundation structures.

In underground water tanks and sumps water stopper is mandatory

to prevent leakage at slab and wall intersections.

This ensures stored water remains clean

and surrounding soil remains protected from seepage.

In lift pits and underground parking areas water leakage can cause major damage

so joint sealing becomes a safety requirement not just waterproofing.

PVC water stopper helps maintain dry and safe underground spaces

improving usability and property value.

For industrial foundations exposed to chemicals and wastewater

special PVC compounds are used for enhanced chemical resistance.

This makes the system suitable for factories treatment plants

and chemical storage facilities.

Infrastructure projects such as tunnels and subways

also depend heavily on internal joint sealing systems.

PVC water stoppers protect tunnel joints from groundwater penetration

ensuring long service life of underground transport structures.

In dam construction water stopper systems are critical

to prevent seepage through concrete blocks and contraction joints.

Without joint sealing water pressure can cause serious structural failures

leading to safety risks and expensive rehabilitation.

High-load PVC water stopper is engineered to handle extreme water pressure

making it ideal for hydraulic structures.

Its durability ensures reliable performance for decades

even in harsh underground environments.

Modern construction standards recommend water stopper installation

in all below-ground concrete structures.

This practice significantly reduces post-construction waterproofing issues

and enhances overall building quality.

PVC water stopper systems are cost-effective

when compared to future repair and injection treatments.

Preventive waterproofing is always more economical

than corrective waterproofing after damage occurs.

Basement owners benefit from dry and usable spaces

which can be converted into living or storage areas.

Developers benefit from reduced maintenance complaints

and higher project reputation.

Contractors benefit from reliable waterproofing solutions

that reduce project risk and warranty claims.

High-load PVC water stoppers are easy to weld at joints

using heat welding methods for continuous sealing.

Proper welding ensures no gaps remain

which could otherwise allow water to pass through.

Installation guidelines must be strictly followed

to achieve maximum sealing efficiency.

Corners and intersections require special attention

to maintain continuous waterproof protection.

With correct design and installation PVC water stopper systems

provide permanent foundation and basement joint sealing.

This makes them an essential component of modern waterproof construction

especially in moisture-prone environments.

Using high-quality PVC water stopper ensures

that concrete joints remain watertight throughout service life.

It protects both structural integrity and interior spaces

from the harmful effects of water infiltration.

Foundation protection directly affects building longevity

so investing in proper joint sealing is a smart decision.

High-load PVC water stopper system delivers reliable performance

where surface coatings alone are not sufficient.

It acts as the last line of defense inside the concrete joint

blocking water permanently.

This internal sealing method remains effective

even if external waterproof layers are damaged.

Therefore professional builders always include PVC water stopper

in their foundation and basement waterproofing design.

With rising construction standards joint sealing is no longer optional

but a mandatory safety and durability requirement.

High-load PVC water stopper systems meet these modern demands

with strength flexibility and proven performance.

They provide confidence that underground structures

will remain dry stable and protected for many years.

Foundation & Basement Joint Sealing | High-Load PVC Water Stopper System

👉 Format: every 2 lines with full stop (.) for SEO

Foundation & basement joint sealing is one of the most critical parts of structural waterproofing

because underground areas are always exposed to soil moisture and water pressure.

High-Load PVC Water Stopper System is specially designed to block water paths

and protect construction joints from leakage and long-term damage.

In modern concrete construction joints are unavoidable

and without proper joint sealing water can easily enter the structure.

PVC water stopper works as a physical barrier inside concrete joints

that prevents water movement even under high hydrostatic pressure.

Foundation slabs and basement walls are highly sensitive to seepage

so professional joint protection is essential for structural safety.

High-load PVC water stoppers are manufactured from flexible yet strong PVC material

that can absorb movement while maintaining complete watertight sealing.

During concrete pouring the water stopper becomes an integral part of the structure

ensuring permanent protection throughout the life of the building.

Basement leakage can lead to corrosion of steel reinforcement

which ultimately weakens the entire concrete structure.

Using PVC water stopper at joints prevents this problem

and increases the durability of foundations and retaining walls.

In areas with high groundwater levels joint protection becomes even more important

because water pressure continuously pushes against the concrete joints.

PVC water stopper creates a continuous sealing line

that blocks seepage paths and prevents water migration.

This system is widely used in residential basements commercial buildings

and large civil engineering structures for reliable waterproofing.

High-load PVC water stopper is ideal for expansion joints

where thermal movement and structural shifts can occur.

Its flexible design allows controlled movement

without breaking the waterproof seal at the joint.

In foundation systems water stopper profiles are placed at critical joints

such as slab to wall joints and wall to wall joints.

These joints are the most common points of leakage

so sealing them correctly ensures complete basement protection.

PVC water stopper is resistant to chemicals present in soil

which protects it from deterioration over long periods of time.

It also resists bacterial growth and does not rot

making it perfect for underground construction environments.

Proper installation of water stopper during concrete casting

is essential to achieve full waterproofing performance.

The profile must be fixed firmly in the center of the joint

so that it remains embedded properly after concrete placement.

Skilled workmanship ensures that the water stopper is not displaced

during vibration and concrete compaction.

Once embedded the water stopper becomes locked inside the joint

creating a permanent waterproof barrier.

High-load water stopper profiles are available in different shapes

to suit various joint designs and structural requirements.

Center bulb profiles are used for expansion joints

while flat profiles are used for construction joints.

Each profile type is designed to manage specific movement patterns

and water pressure conditions in concrete structures.

Foundation waterproofing systems are incomplete without joint protection

because membranes alone cannot seal dynamic concrete joints.

PVC water stopper complements surface waterproofing systems

by providing internal joint sealing protection.

When used together they form a complete waterproofing solution

that protects structures from both surface and internal water ingress.

Basement waterproofing failures often occur due to neglected joint sealing

which results in costly repair work after construction.

Installing PVC water stopper during construction prevents such future expenses

and ensures long-term waterproof performance.

High-load PVC water stoppers are tested for tensile strength and flexibility

to perform under heavy structural loads and movement.

They maintain their shape even under high compression

which is essential in deep foundation structures.

In underground water tanks and sumps water stopper is mandatory

to prevent leakage at slab and wall intersections.

This ensures stored water remains clean

and surrounding soil remains protected from seepage.

In lift pits and underground parking areas water leakage can cause major damage

so joint sealing becomes a safety requirement not just waterproofing.

PVC water stopper helps maintain dry and safe underground spaces

improving usability and property value.

For industrial foundations exposed to chemicals and wastewater

special PVC compounds are used for enhanced chemical resistance.

This makes the system suitable for factories treatment plants

and chemical storage facilities.

Infrastructure projects such as tunnels and subways

also depend heavily on internal joint sealing systems.

PVC water stoppers protect tunnel joints from groundwater penetration

ensuring long service life of underground transport structures.

In dam construction water stopper systems are critical

to prevent seepage through concrete blocks and contraction joints.

Without joint sealing water pressure can cause serious structural failures

leading to safety risks and expensive rehabilitation.

High-load PVC water stopper is engineered to handle extreme water pressure

making it ideal for hydraulic structures.

Its durability ensures reliable performance for decades

even in harsh underground environments.

Modern construction standards recommend water stopper installation

in all below-ground concrete structures.

This practice significantly reduces post-construction waterproofing issues

and enhances overall building quality.

PVC water stopper systems are cost-effective

when compared to future repair and injection treatments.

Preventive waterproofing is always more economical

than corrective waterproofing after damage occurs.

Basement owners benefit from dry and usable spaces

which can be converted into living or storage areas.

Developers benefit from reduced maintenance complaints

and higher project reputation.

Contractors benefit from reliable waterproofing solutions

that reduce project risk and warranty claims.

High-load PVC water stoppers are easy to weld at joints

using heat welding methods for continuous sealing.

Proper welding ensures no gaps remain

which could otherwise allow water to pass through.

Installation guidelines must be strictly followed

to achieve maximum sealing efficiency.

Corners and intersections require special attention

to maintain continuous waterproof protection.

With correct design and installation PVC water stopper systems

provide permanent foundation and basement joint sealing.

This makes them an essential component of modern waterproof construction

especially in moisture-prone environments.

Using high-quality PVC water stopper ensures

that concrete joints remain watertight throughout service life.

It protects both structural integrity and interior spaces

from the harmful effects of water infiltration.

Foundation protection directly affects building longevity

so investing in proper joint sealing is a smart decision.

High-load PVC water stopper system delivers reliable performance

where surface coatings alone are not sufficient.

It acts as the last line of defense inside the concrete joint

blocking water permanently.

This internal sealing method remains effective

even if external waterproof layers are damaged.

Therefore professional builders always include PVC water stopper

in their foundation and basement waterproofing design.

With rising construction standards joint sealing is no longer optional

but a mandatory safety and durability requirement.

High-load PVC water stopper systems meet these modern demands

with strength flexibility and proven performance.

They provide confidence that underground structures

will remain dry stable and protected for many years.

Foundation & Basement Joint Sealing | High-Load PVC Water Stopper System

👉 Format: every 2 lines with full stop (.) for SEO

Foundation & basement joint sealing is one of the most critical parts of structural waterproofing

because underground areas are always exposed to soil moisture and water pressure.

High-Load PVC Water Stopper System is specially designed to block water paths

and protect construction joints from leakage and long-term damage.

In modern concrete construction joints are unavoidable

and without proper joint sealing water can easily enter the structure.

PVC water stopper works as a physical barrier inside concrete joints

that prevents water movement even under high hydrostatic pressure.

Foundation slabs and basement walls are highly sensitive to seepage

so professional joint protection is essential for structural safety.

High-load PVC water stoppers are manufactured from flexible yet strong PVC material

that can absorb movement while maintaining complete watertight sealing.

During concrete pouring the water stopper becomes an integral part of the structure

ensuring permanent protection throughout the life of the building.

Basement leakage can lead to corrosion of steel reinforcement

which ultimately weakens the entire concrete structure.

Using PVC water stopper at joints prevents this problem

and increases the durability of foundations and retaining walls.

In areas with high groundwater levels joint protection becomes even more important

because water pressure continuously pushes against the concrete joints.

PVC water stopper creates a continuous sealing line

that blocks seepage paths and prevents water migration.

This system is widely used in residential basements commercial buildings

and large civil engineering structures for reliable waterproofing.

High-load PVC water stopper is ideal for expansion joints

where thermal movement and structural shifts can occur.

Its flexible design allows controlled movement

without breaking the waterproof seal at the joint.

In foundation systems water stopper profiles are placed at critical joints

such as slab to wall joints and wall to wall joints.

These joints are the most common points of leakage

so sealing them correctly ensures complete basement protection.

PVC water stopper is resistant to chemicals present in soil

which protects it from deterioration over long periods of time.

It also resists bacterial growth and does not rot

making it perfect for underground construction environments.

Proper installation of water stopper during concrete casting

is essential to achieve full waterproofing performance.

The profile must be fixed firmly in the center of the joint

so that it remains embedded properly after concrete placement.

Skilled workmanship ensures that the water stopper is not displaced

during vibration and concrete compaction.

Once embedded the water stopper becomes locked inside the joint

creating a permanent waterproof barrier.

High-load water stopper profiles are available in different shapes

to suit various joint designs and structural requirements.

Center bulb profiles are used for expansion joints

while flat profiles are used for construction joints.

Each profile type is designed to manage specific movement patterns

and water pressure conditions in concrete structures.

Foundation waterproofing systems are incomplete without joint protection

because membranes alone cannot seal dynamic concrete joints.

PVC water stopper complements surface waterproofing systems

by providing internal joint sealing protection.

When used together they form a complete waterproofing solution

that protects structures from both surface and internal water ingress.

Basement waterproofing failures often occur due to neglected joint sealing

which results in costly repair work after construction.

Installing PVC water stopper during construction prevents such future expenses

and ensures long-term waterproof performance.

High-load PVC water stoppers are tested for tensile strength and flexibility

to perform under heavy structural loads and movement.

They maintain their shape even under high compression

which is essential in deep foundation structures.

In underground water tanks and sumps water stopper is mandatory

to prevent leakage at slab and wall intersections.

This ensures stored water remains clean

and surrounding soil remains protected from seepage.

In lift pits and underground parking areas water leakage can cause major damage

so joint sealing becomes a safety requirement not just waterproofing.

PVC water stopper helps maintain dry and safe underground spaces

improving usability and property value.

For industrial foundations exposed to chemicals and wastewater

special PVC compounds are used for enhanced chemical resistance.

This makes the system suitable for factories treatment plants

and chemical storage facilities.

Infrastructure projects such as tunnels and subways

also depend heavily on internal joint sealing systems.

PVC water stoppers protect tunnel joints from groundwater penetration

ensuring long service life of underground transport structures.

In dam construction water stopper systems are critical

to prevent seepage through concrete blocks and contraction joints.

Without joint sealing water pressure can cause serious structural failures

leading to safety risks and expensive rehabilitation.

High-load PVC water stopper is engineered to handle extreme water pressure

making it ideal for hydraulic structures.

Its durability ensures reliable performance for decades

even in harsh underground environments.

Modern construction standards recommend water stopper installation

in all below-ground concrete structures.

This practice significantly reduces post-construction waterproofing issues

and enhances overall building quality.

PVC water stopper systems are cost-effective

when compared to future repair and injection treatments.

Preventive waterproofing is always more economical

than corrective waterproofing after damage occurs.

Basement owners benefit from dry and usable spaces

which can be converted into living or storage areas.

Developers benefit from reduced maintenance complaints

and higher project reputation.

Contractors benefit from reliable waterproofing solutions

that reduce project risk and warranty claims.

High-load PVC water stoppers are easy to weld at joints

using heat welding methods for continuous sealing.

Proper welding ensures no gaps remain

which could otherwise allow water to pass through.

Installation guidelines must be strictly followed

to achieve maximum sealing efficiency.

Corners and intersections require special attention

to maintain continuous waterproof protection.

With correct design and installation PVC water stopper systems

provide permanent foundation and basement joint sealing.

This makes them an essential component of modern waterproof construction

especially in moisture-prone environments.

Using high-quality PVC water stopper ensures

that concrete joints remain watertight throughout service life.

It protects both structural integrity and interior spaces

from the harmful effects of water infiltration.

Foundation protection directly affects building longevity

so investing in proper joint sealing is a smart decision.

High-load PVC water stopper system delivers reliable performance

where surface coatings alone are not sufficient.

It acts as the last line of defense inside the concrete joint

blocking water permanently.

This internal sealing method remains effective

even if external waterproof layers are damaged.

Therefore professional builders always include PVC water stopper

in their foundation and basement waterproofing design.

With rising construction standards joint sealing is no longer optional

but a mandatory safety and durability requirement.

High-load PVC water stopper systems meet these modern demands

with strength flexibility and proven performance.

They provide confidence that underground structures

will remain dry stable and protected for many years.

FOUNDATIONFOUNDATIONFOUNDATIONFOUNDATIONFOUNDATIONFOUNDATIONFOUNDATIONFOUNDATIONFOUNDATIONFOUNDATIONFOUNDATIONFOUNDATIONFOUNDATION

🔷 Importance of Joint Sealing in Foundations and Basements

Foundation and basement joints are the most vulnerable points for water leakage.

Without proper sealing, groundwater pressure can force water through even the smallest gaps.

🔹 Why Concrete Joints Leak

Concrete shrinks and expands due to temperature changes.

This movement creates micro-gaps that allow water penetration.

🔸 Effect of Hydrostatic Pressure

Underground structures face continuous water pressure.

If joints are not sealed internally, water will always find a path inside.

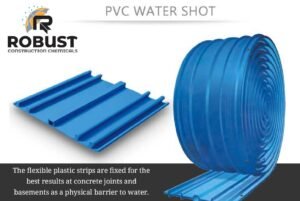

🔷 What is a High-Load PVC Water Stopper System

A PVC water stopper is an internal joint sealing profile embedded inside concrete joints.

It blocks water movement and protects the structure from internal leakage.

🔹 Working Principle of PVC Water Stopper

The stopper creates a continuous barrier within the joint.

Even if water reaches the joint, it cannot pass through the embedded PVC profile.

🔸 Permanent Internal Waterproofing

Unlike surface coatings, PVC water stopper becomes part of the concrete.

This ensures long-term and permanent waterproof protection.

🔷 Key Features of High-Load PVC Water Stopper

High-load PVC water stoppers are engineered for heavy-duty construction applications.

They perform reliably under high structural stress and water pressure.

🔹 High Flexibility with Strong Recovery

The material bends with joint movement and returns to its original shape.

This prevents cracking and seal failure.

🔸 Suitable for Expansion and Construction Joints

Different profile designs allow use in both static and moving joints.

This makes the system versatile for all joint types.

🔷 Chemical and Moisture Resistance Properties

Underground environments contain aggressive chemicals and moisture.

PVC water stoppers are designed to resist both.

🔹 Resistance to Soil Chemicals and Salts

The material does not react with chemicals present in soil or groundwater.

This ensures long service life even in harsh conditions.

🔸 Protection Against Mold and Decay

PVC does not rot or support bacterial growth.

This keeps the joint area hygienic and structurally safe.

🔷 Application Areas of PVC Water Stopper System

This system is widely used in both small and large construction projects.

It provides reliable waterproofing for critical structural joints.

🔹 Residential Foundations and Basements

Protects homes from dampness and water seepage.

Ensures dry living and storage spaces below ground level.

🔸 Commercial and Industrial Structures

Used in plazas, factories, and warehouses.

Prevents operational damage caused by water infiltration.

🔷 Use in Water Retaining Structures

Structures that store or block water require the highest level of joint protection.

PVC water stopper plays a key role in such projects.

🔹 Water Tanks and Swimming Pools

Prevents leakage at slab and wall intersections.

Ensures long-term water retention without seepage.

🔸 Dams and Canals

Used in contraction joints and construction joints.

Protects against high-pressure water flow.

🔷 Installation Method of PVC Water Stopper

Correct installation is essential for maximum waterproofing performance.

Improper placement can reduce effectiveness.

🔹 Fixing During Reinforcement Stage

Water stopper is tied to steel bars before concrete pouring.

This ensures it remains centered in the joint.

🔸 Welding and Joint Connections

Ends are heat-welded for continuous sealing.

No gaps should remain between profiles.

🔷 Types of PVC Water Stopper Profiles

Different construction joints require different profile designs.

Selection depends on joint movement and water pressure.

🔹 Center Bulb Water Stopper

Used for expansion joints with movement.

Allows controlled movement while maintaining seal.

🔸 Flat Strip Water Stopper

Used in construction joints with no movement.

Provides simple and effective sealing.

🔷 Advantages Over Surface Waterproofing Methods

Surface coatings alone cannot protect internal joints.

Internal sealing is always more reliable.

🔹 Permanent Protection Inside Concrete

PVC water stopper remains effective even if surface layers fail.

This ensures backup waterproofing safety.

🔸 Reduced Maintenance and Repair Cost

Prevents leakage before it happens.

Eliminates costly post-construction repairs.

🔷 Long-Term Structural Protection Benefits

Joint sealing directly affects building durability.

Water ingress weakens concrete and steel reinforcement.

🔹 Prevention of Steel Corrosion

Keeps moisture away from reinforcement bars.

Extends structural lifespan significantly.

🔸 Minimization of Concrete Cracking

Reduces internal stress caused by moisture movement.

Helps maintain structural stability.

🔷 Why Choose ROBUST PVC Water Stopper System

ROBUST offers construction-grade waterproofing solutions trusted by professionals.

Products are designed for Pakistan’s climate and construction conditions.

🔹 Quality-Controlled Manufacturing

Each profile is tested for strength and flexibility.

Ensures reliable performance on site.

🔸 Compatible with Complete Waterproofing Systems

Works perfectly with ROBUST membranes, PU coatings, and bitumen systems.

Provides total joint and surface protection.

🔷 Conclusion: Essential Solution for Underground Waterproofing

Foundation and basement joint sealing is impossible without internal protection.

High-load PVC water stopper provides the strongest and most reliable solution.

🔹 Smart Investment for Long-Term Safety

Prevents leakage, reduces maintenance, and protects structure.

Delivers long-term value for all construction projects.

🔸 Trusted Choice for Professional Construction

Used by engineers, contractors, and developers.

Ensures dry, strong, and durable underground structures.