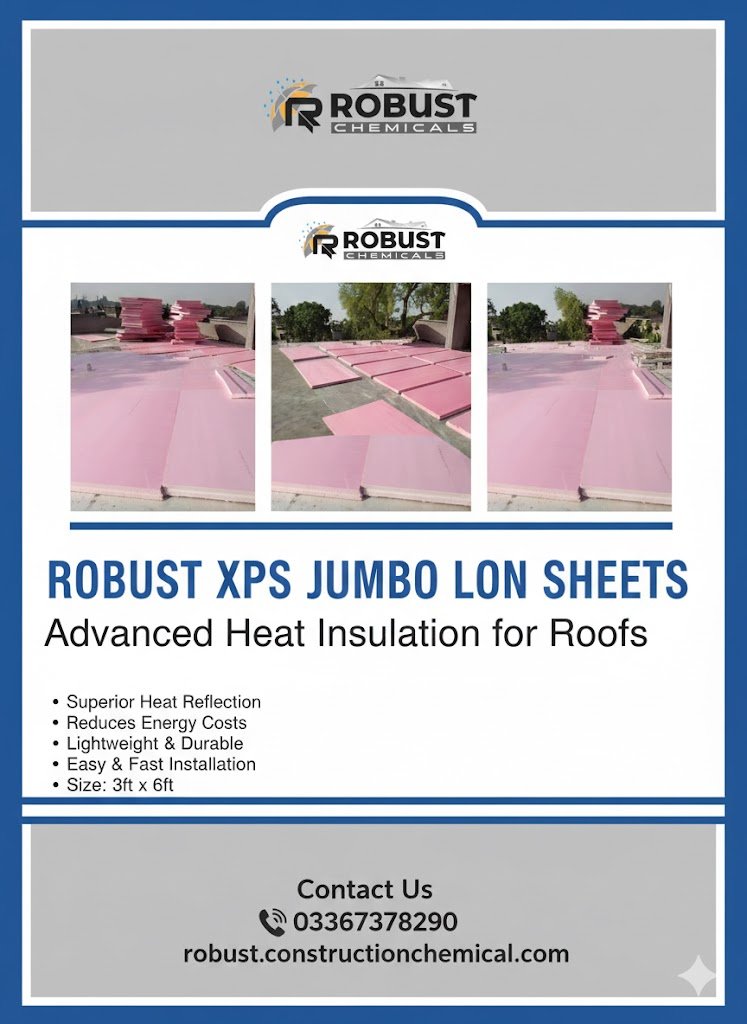

High-Density Insulation Boards | Energy-Saving Jambolone XPS Sheets for Roofing

High-Density Insulation Boards are advanced thermal insulation materials designed to reduce heat transfer in buildings and improve indoor comfort.

They are widely used in modern construction projects where energy efficiency, durability, and moisture resistance are essential requirements.

Energy-Saving Jambolone XPS Sheets for Roofing provide superior thermal performance and long-term stability.

These sheets are manufactured using extruded polystyrene technology that forms a closed-cell structure for maximum insulation efficiency.

H2: What Are High-Density Jambolone XPS Insulation Boards

High-density Jambolone XPS insulation boards are rigid thermal panels made from extruded polystyrene foam.

They are specially engineered to resist heat flow, moisture penetration, and compressive loads in construction systems.

These boards are commonly used for roof insulation, wall insulation, floor insulation, and basement thermal protection.

Their consistent cell structure allows uniform thermal resistance across the entire surface of the sheet.

XPS insulation boards maintain performance even in extreme weather conditions found in Pakistan.

They remain effective during intense summer heat and monsoon moisture exposure.

H3: Composition and Manufacturing Process of XPS Sheets

Jambolone XPS sheets are produced using extrusion technology where polystyrene is melted and mixed with blowing agents.

This mixture is then forced through molds to form rigid foam boards with uniform density.

The extrusion process creates a closed-cell foam structure that prevents water absorption.

This structure also improves mechanical strength and long-term thermal stability.

Unlike EPS thermopore sheets, XPS boards have higher compressive strength and lower water absorption.

This makes them ideal for roofing and load-bearing insulation applications.

H3: Closed-Cell Structure Benefits

The closed-cell structure of XPS sheets traps air within microscopic cells.

This trapped air acts as a barrier against heat transfer and moisture penetration.

Water resistance helps prevent mold growth and structural damage.

This feature increases the lifespan of roofing and insulation systems.

Closed-cell insulation also prevents thermal bridging in construction joints.

This improves overall energy efficiency of the building envelope.

H2: Why High-Density Insulation Boards Are Best for Roofing

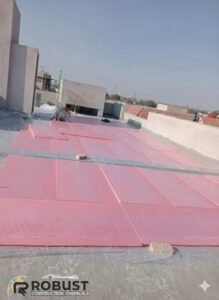

Roofing is the most exposed part of any building to solar heat radiation.

Using high-density XPS boards significantly reduces heat transfer into indoor spaces.

These boards reduce roof surface temperature and interior cooling demand.

This results in lower electricity consumption and reduced air conditioning costs.

High-density boards also provide strong load-bearing capacity.

They can support waterproofing membranes, tiles, and protective screeds.

H3: Thermal Resistance Performance

XPS insulation boards provide high R-value per inch thickness.

This allows effective insulation with thinner material layers.

High R-value improves energy conservation in residential and commercial buildings.

It keeps indoor spaces cooler during summer and warmer during winter.

Consistent thermal resistance across the board surface prevents hot spots.

This ensures uniform temperature control throughout the building.

H3: Moisture Resistance in Roof Applications

Roof insulation materials must resist rainwater and humidity.

Jambolone XPS boards absorb minimal water due to closed-cell composition.

Even if exposed to water, thermal performance remains stable.

This prevents insulation degradation over time.

Moisture resistance also protects waterproofing membranes installed above insulation.

This ensures long-lasting roof systems with fewer maintenance issues.

H2: Applications of Jambolone XPS Sheets in Construction

Jambolone XPS sheets are used in multiple construction applications.

They offer flexibility for both residential and industrial building systems.

They are ideal for flat roofs, sloped roofs, cavity walls, and floor insulation.

They also perform well in cold storage facilities and industrial sheds.

Their lightweight nature makes installation easy and cost-effective.

Transportation and handling costs are also reduced at project sites.

H3: Roof Insulation Systems

XPS boards are placed below waterproofing membranes in inverted roofs.

They protect membranes from thermal stress and mechanical damage.

They can also be used above roof slabs in conventional roofing systems.

This reduces thermal load directly on concrete structures.

In industrial buildings, they help maintain stable internal temperatures.

This improves productivity and equipment performance.

H3: Wall and Façade Insulation

XPS boards are used in cavity wall insulation and external wall systems.

They prevent heat penetration and reduce indoor temperature fluctuations.

External insulation improves building energy ratings and comfort.

It also protects structural walls from environmental exposure.

Façade insulation using XPS boards enhances modern building aesthetics.

It allows flexible design options for architects and engineers.

H3: Floor and Basement Insulation

Basement insulation prevents ground moisture and cold transfer.

XPS boards perform well under floor slabs due to high compressive strength.

They support heavy loads without deformation.

This ensures long-term structural stability and insulation efficiency.

Floor insulation improves indoor thermal comfort in winter seasons.

It also reduces condensation and dampness problems.

H2: Advantages of High-Density Jambolone XPS Insulation Boards

High-density XPS boards provide multiple construction benefits.

They improve energy efficiency, durability, and building performance.

They reduce thermal expansion stresses in roof structures.

This helps prevent cracks and waterproofing failure.

Their resistance to chemicals and biological growth improves hygiene.

They are safe for use in hospitals and food processing facilities.

H3: Long-Term Durability

XPS insulation does not settle or shrink over time.

It maintains thickness and performance throughout building life.

High-density boards resist crushing under load.

This makes them suitable for heavy-duty applications.

They do not degrade when exposed to moisture or temperature cycles.

This ensures reliable insulation for decades.

H3: Energy Cost Savings

Energy-efficient insulation reduces HVAC operational load.

This leads to significant electricity bill savings.

Buildings with proper insulation require less mechanical cooling.

This also reduces carbon footprint and environmental impact.

Energy savings improve return on investment for construction projects.

This makes XPS insulation a cost-effective long-term solution.

H2: Installation Guidelines for XPS Roofing Insulation

Proper installation ensures maximum insulation performance.

Surface preparation is essential before placing insulation boards.

Roof slabs should be clean, dry, and free from sharp objects.

Boards should be laid tightly with minimal gaps.

Joints can be sealed using compatible adhesive or tape.

This prevents air leakage and thermal bridging.

H3: Waterproofing Compatibility

XPS boards are compatible with bitumen membranes and liquid waterproof coatings.

They work well with PU liquid rubber and cementitious waterproofing systems.

In inverted roofs, waterproofing is applied before insulation boards.

This protects membranes from thermal shock and UV exposure.

Protective layers should be installed above insulation boards.

This prevents mechanical damage from foot traffic.

H3: Safety and Handling

XPS boards are lightweight and easy to cut.

Standard cutting tools can be used for sizing.

Workers should avoid exposing boards to open flames.

Although fire-retardant grades are available, safety precautions are necessary.

Storage should be in shaded and dry areas.

This prevents UV degradation before installation.

H2: Difference Between XPS and EPS Insulation Sheets

Many builders confuse XPS with EPS thermopore sheets.

However, performance differences are significant.

EPS has open-cell structure and higher water absorption.

XPS has closed-cell structure and very low water absorption.

XPS provides higher compressive strength than EPS.

This makes XPS suitable for roofing and load-bearing floors.

H3: Thermal Efficiency Comparison

XPS offers higher thermal resistance per thickness than EPS.

This allows thinner insulation layers for the same performance.

EPS may lose insulation efficiency when wet.

XPS maintains thermal stability even after water exposure.

For long-term roofing insulation, XPS is more reliable.

It ensures consistent energy savings over time.

H3: Structural Strength Comparison

EPS is softer and compresses under load.

XPS resists deformation under heavy construction loads.

Roof systems require materials that can bear membrane and screed loads.

XPS meets these requirements effectively.

This strength also prevents cracking of surface finishes.

It contributes to longer roof system life.

H2: Why Choose Energy-Saving Jambolone XPS Sheets in Pakistan

Pakistan experiences extreme summer temperatures and energy shortages.

Thermal insulation is essential for sustainable construction.

XPS sheets reduce indoor temperature and cooling demand.

This helps reduce electricity consumption during peak seasons.

They also protect buildings from monsoon moisture damage.

This improves building durability and occupant comfort.

H3: Suitable for Residential Projects

Homes benefit from reduced heat gain through roofs and walls.

This creates comfortable living spaces without excessive air conditioning.

Proper insulation improves property value and living standards.

It also supports eco-friendly housing development.

Homeowners experience reduced maintenance and repair costs.

This makes XPS insulation a smart investment.

H3: Suitable for Commercial and Industrial Buildings

Factories and warehouses require temperature stability.

XPS insulation supports product quality and equipment efficiency.

Shopping malls and offices benefit from controlled indoor climate.

This improves customer comfort and employee productivity.

Cold storage facilities require high-performance insulation.

XPS boards provide reliable thermal barriers for refrigeration systems.

H2: Role of Insulation in Sustainable Construction

Sustainable buildings focus on reducing energy consumption.

Insulation is one of the most effective sustainability strategies.

By reducing HVAC usage, buildings lower carbon emissions.

This supports environmental protection and climate goals.

XPS boards are recyclable and environmentally friendly.

They support green building certification programs.

H3: Environmental Impact Reduction

Lower energy usage reduces fossil fuel consumption.

This contributes to cleaner air and reduced pollution.

Buildings with insulation require fewer mechanical upgrades.

This reduces construction waste and material usage.

Sustainable insulation supports long-term urban development.

It helps cities manage energy demand effectively.

H3: Compliance with Modern Building Codes

Modern construction standards require energy-efficient materials.

XPS insulation helps meet these regulatory requirements.

Government projects increasingly demand thermal insulation.

This increases demand for high-quality insulation products.

Builders using XPS comply with international construction practices.

This improves project quality and market competitiveness.

H2: Choosing the Right Thickness of XPS Boards

Insulation thickness depends on climate and building design.

Higher thickness provides greater thermal resistance.

Roof insulation typically uses thicker boards than wall insulation.

This provides maximum heat protection from direct sunlight.

Multiple layers can be installed for higher insulation values.

This also helps reduce thermal bridging.

H3: Standard Thickness Options

XPS boards are available in multiple thicknesses.

Common sizes include 25mm, 40mm, 50mm, and above.

Selection depends on insulation performance requirements.

Consulting insulation experts ensures correct specification.

Proper thickness improves energy efficiency and comfort.

It also improves return on insulation investment.

H3: Load-Bearing Requirements

Roofs with heavy foot traffic require higher density boards.

This prevents compression and surface damage.

Industrial floors require high compressive strength insulation.

XPS boards meet these structural requirements.

Proper material selection prevents future repair costs.

It ensures long-term building safety and performance.

H2: Conclusion – Best Choice for Modern Roofing Insulation

High-Density Insulation Boards provide reliable thermal protection.

They improve comfort, durability, and energy efficiency.

Energy-Saving Jambolone XPS Sheets for Roofing are ideal for Pakistan’s climate.

They protect buildings from heat and moisture challenges.

Their strength, stability, and performance make them suitable for all building types.

From homes to factories, they deliver long-term insulation solutions.

For construction companies and waterproofing material suppliers like your business,

XPS insulation boards are a premium product that enhances project quality and client satisfaction.

High-Density Insulation Boards | Energy-Saving Jambolone XPS Sheets for Roofing

High-Density Insulation Boards are advanced thermal insulation materials designed to reduce heat transfer in buildings and improve indoor comfort.

They are widely used in modern construction projects where energy efficiency, durability, and moisture resistance are essential requirements.

Energy-Saving Jambolone XPS Sheets for Roofing provide superior thermal performance and long-term stability.

These sheets are manufactured using extruded polystyrene technology that forms a closed-cell structure for maximum insulation efficiency.

H2: What Are High-Density Jambolone XPS Insulation Boards

High-density Jambolone XPS insulation boards are rigid thermal panels made from extruded polystyrene foam.

They are specially engineered to resist heat flow, moisture penetration, and compressive loads in construction systems.

These boards are commonly used for roof insulation, wall insulation, floor insulation, and basement thermal protection.

Their consistent cell structure allows uniform thermal resistance across the entire surface of the sheet.

XPS insulation boards maintain performance even in extreme weather conditions found in Pakistan.

They remain effective during intense summer heat and monsoon moisture exposure.

H3: Composition and Manufacturing Process of XPS Sheets

Jambolone XPS sheets are produced using extrusion technology where polystyrene is melted and mixed with blowing agents.

This mixture is then forced through molds to form rigid foam boards with uniform density.

The extrusion process creates a closed-cell foam structure that prevents water absorption.

This structure also improves mechanical strength and long-term thermal stability.

Unlike EPS thermopore sheets, XPS boards have higher compressive strength and lower water absorption.

This makes them ideal for roofing and load-bearing insulation applications.

H3: Closed-Cell Structure Benefits

The closed-cell structure of XPS sheets traps air within microscopic cells.

This trapped air acts as a barrier against heat transfer and moisture penetration.

Water resistance helps prevent mold growth and structural damage.

This feature increases the lifespan of roofing and insulation systems.

Closed-cell insulation also prevents thermal bridging in construction joints.

This improves overall energy efficiency of the building envelope.

H2: Why High-Density Insulation Boards Are Best for Roofing

Roofing is the most exposed part of any building to solar heat radiation.

Using high-density XPS boards significantly reduces heat transfer into indoor spaces.

These boards reduce roof surface temperature and interior cooling demand.

This results in lower electricity consumption and reduced air conditioning costs.

High-density boards also provide strong load-bearing capacity.

They can support waterproofing membranes, tiles, and protective screeds.

H3: Thermal Resistance Performance

XPS insulation boards provide high R-value per inch thickness.

This allows effective insulation with thinner material layers.

High R-value improves energy conservation in residential and commercial buildings.

It keeps indoor spaces cooler during summer and warmer during winter.

Consistent thermal resistance across the board surface prevents hot spots.

This ensures uniform temperature control throughout the building.

H3: Moisture Resistance in Roof Applications

Roof insulation materials must resist rainwater and humidity.

Jambolone XPS boards absorb minimal water due to closed-cell composition.

Even if exposed to water, thermal performance remains stable.

This prevents insulation degradation over time.

Moisture resistance also protects waterproofing membranes installed above insulation.

This ensures long-lasting roof systems with fewer maintenance issues.

H2: Applications of Jambolone XPS Sheets in Construction

Jambolone XPS sheets are used in multiple construction applications.

They offer flexibility for both residential and industrial building systems.

They are ideal for flat roofs, sloped roofs, cavity walls, and floor insulation.

They also perform well in cold storage facilities and industrial sheds.

Their lightweight nature makes installation easy and cost-effective.

Transportation and handling costs are also reduced at project sites.

H3: Roof Insulation Systems

XPS boards are placed below waterproofing membranes in inverted roofs.

They protect membranes from thermal stress and mechanical damage.

They can also be used above roof slabs in conventional roofing systems.

This reduces thermal load directly on concrete structures.

In industrial buildings, they help maintain stable internal temperatures.

This improves productivity and equipment performance.

H3: Wall and Façade Insulation

XPS boards are used in cavity wall insulation and external wall systems.

They prevent heat penetration and reduce indoor temperature fluctuations.

External insulation improves building energy ratings and comfort.

It also protects structural walls from environmental exposure.

Façade insulation using XPS boards enhances modern building aesthetics.

It allows flexible design options for architects and engineers.

H3: Floor and Basement Insulation

Basement insulation prevents ground moisture and cold transfer.

XPS boards perform well under floor slabs due to high compressive strength.

They support heavy loads without deformation.

This ensures long-term structural stability and insulation efficiency.

Floor insulation improves indoor thermal comfort in winter seasons.

It also reduces condensation and dampness problems.

H2: Advantages of High-Density Jambolone XPS Insulation Boards

High-density XPS boards provide multiple construction benefits.

They improve energy efficiency, durability, and building performance.

They reduce thermal expansion stresses in roof structures.

This helps prevent cracks and waterproofing failure.

Their resistance to chemicals and biological growth improves hygiene.

They are safe for use in hospitals and food processing facilities.

H3: Long-Term Durability

XPS insulation does not settle or shrink over time.

It maintains thickness and performance throughout building life.

High-density boards resist crushing under load.

This makes them suitable for heavy-duty applications.

They do not degrade when exposed to moisture or temperature cycles.

This ensures reliable insulation for decades.

H3: Energy Cost Savings

Energy-efficient insulation reduces HVAC operational load.

This leads to significant electricity bill savings.

Buildings with proper insulation require less mechanical cooling.

This also reduces carbon footprint and environmental impact.

Energy savings improve return on investment for construction projects.

This makes XPS insulation a cost-effective long-term solution.

H2: Installation Guidelines for XPS Roofing Insulation

Proper installation ensures maximum insulation performance.

Surface preparation is essential before placing insulation boards.

Roof slabs should be clean, dry, and free from sharp objects.

Boards should be laid tightly with minimal gaps.

Joints can be sealed using compatible adhesive or tape.

This prevents air leakage and thermal bridging.

H3: Waterproofing Compatibility

XPS boards are compatible with bitumen membranes and liquid waterproof coatings.

They work well with PU liquid rubber and cementitious waterproofing systems.

In inverted roofs, waterproofing is applied before insulation boards.

This protects membranes from thermal shock and UV exposure.

Protective layers should be installed above insulation boards.

This prevents mechanical damage from foot traffic.

H3: Safety and Handling

XPS boards are lightweight and easy to cut.

Standard cutting tools can be used for sizing.

Workers should avoid exposing boards to open flames.

Although fire-retardant grades are available, safety precautions are necessary.

Storage should be in shaded and dry areas.

This prevents UV degradation before installation.

H2: Difference Between XPS and EPS Insulation Sheets

Many builders confuse XPS with EPS thermopore sheets.

However, performance differences are significant.

EPS has open-cell structure and higher water absorption.

XPS has closed-cell structure and very low water absorption.

XPS provides higher compressive strength than EPS.

This makes XPS suitable for roofing and load-bearing floors.

H3: Thermal Efficiency Comparison

XPS offers higher thermal resistance per thickness than EPS.

This allows thinner insulation layers for the same performance.

EPS may lose insulation efficiency when wet.

XPS maintains thermal stability even after water exposure.

For long-term roofing insulation, XPS is more reliable.

It ensures consistent energy savings over time.

H3: Structural Strength Comparison

EPS is softer and compresses under load.

XPS resists deformation under heavy construction loads.

Roof systems require materials that can bear membrane and screed loads.

XPS meets these requirements effectively.

This strength also prevents cracking of surface finishes.

It contributes to longer roof system life.

H2: Why Choose Energy-Saving Jambolone XPS Sheets in Pakistan

Pakistan experiences extreme summer temperatures and energy shortages.

Thermal insulation is essential for sustainable construction.

XPS sheets reduce indoor temperature and cooling demand.

This helps reduce electricity consumption during peak seasons.

They also protect buildings from monsoon moisture damage.

This improves building durability and occupant comfort.

H3: Suitable for Residential Projects

Homes benefit from reduced heat gain through roofs and walls.

This creates comfortable living spaces without excessive air conditioning.

Proper insulation improves property value and living standards.

It also supports eco-friendly housing development.

Homeowners experience reduced maintenance and repair costs.

This makes XPS insulation a smart investment.

H3: Suitable for Commercial and Industrial Buildings

Factories and warehouses require temperature stability.

XPS insulation supports product quality and equipment efficiency.

Shopping malls and offices benefit from controlled indoor climate.

This improves customer comfort and employee productivity.

Cold storage facilities require high-performance insulation.

XPS boards provide reliable thermal barriers for refrigeration systems.

H2: Role of Insulation in Sustainable Construction

Sustainable buildings focus on reducing energy consumption.

Insulation is one of the most effective sustainability strategies.

By reducing HVAC usage, buildings lower carbon emissions.

This supports environmental protection and climate goals.

XPS boards are recyclable and environmentally friendly.

They support green building certification programs.

H3: Environmental Impact Reduction

Lower energy usage reduces fossil fuel consumption.

This contributes to cleaner air and reduced pollution.

Buildings with insulation require fewer mechanical upgrades.

This reduces construction waste and material usage.

Sustainable insulation supports long-term urban development.

It helps cities manage energy demand effectively.

H3: Compliance with Modern Building Codes

Modern construction standards require energy-efficient materials.

XPS insulation helps meet these regulatory requirements.

Government projects increasingly demand thermal insulation.

This increases demand for high-quality insulation products.

Builders using XPS comply with international construction practices.

This improves project quality and market competitiveness.

H2: Choosing the Right Thickness of XPS Boards

Insulation thickness depends on climate and building design.

Higher thickness provides greater thermal resistance.

Roof insulation typically uses thicker boards than wall insulation.

This provides maximum heat protection from direct sunlight.

Multiple layers can be installed for higher insulation values.

This also helps reduce thermal bridging.

H3: Standard Thickness Options

XPS boards are available in multiple thicknesses.

Common sizes include 25mm, 40mm, 50mm, and above.

Selection depends on insulation performance requirements.

Consulting insulation experts ensures correct specification.

Proper thickness improves energy efficiency and comfort.

It also improves return on insulation investment.

H3: Load-Bearing Requirements

Roofs with heavy foot traffic require higher density boards.

This prevents compression and surface damage.

Industrial floors require high compressive strength insulation.

XPS boards meet these structural requirements.

Proper material selection prevents future repair costs.

It ensures long-term building safety and performance.

H2: Conclusion – Best Choice for Modern Roofing Insulation

High-Density Insulation Boards provide reliable thermal protection.

They improve comfort, durability, and energy efficiency.

Energy-Saving Jambolone XPS Sheets for Roofing are ideal for Pakistan’s climate.

They protect buildings from heat and moisture challenges.

Their strength, stability, and performance make them suitable for all building types.

From homes to factories, they deliver long-term insulation solutions.

For construction companies and waterproofing material suppliers like your business,

XPS insulation boards are a premium product that enhances project quality and client satisfaction.