✅ Permanent Leak Control Strip | Professional PVC Water Stopper for Infrastructure

Permanent leak control strip solutions play a vital role in modern infrastructure projects where long term water resistance determines structural durability and safety, and professional PVC water stopper systems are widely trusted because they create a continuous physical barrier inside concrete joints that blocks groundwater pressure, surface runoff, chemical seepage, and moisture migration before it can damage foundations, basements, tunnels, retaining walls, bridges, reservoirs, water treatment plants, underground parking structures, and heavy civil construction environments that demand zero leakage tolerance while maintaining flexibility under thermal movement, settlement, vibration, and load transfer forces that naturally occur in reinforced concrete structures over time.

Unlike surface coatings that rely on adhesion alone, PVC water stoppers are embedded directly into the concrete joint during pouring, allowing the strip to become an integral part of the structure itself, which ensures permanent leak control throughout the service life of the building or infrastructure facility while resisting hydrostatic pressure, soil moisture, aggressive salts, mild chemicals, and continuous wet conditions commonly found in underground and marine environments where traditional sealing materials may fail prematurely.

Professional grade PVC water stopper profiles are manufactured using high quality flexible polyvinyl chloride compounds that balance elasticity, tensile strength, tear resistance, and dimensional stability, enabling the strip to deform with joint movement without cracking, shrinking, or losing watertight integrity, which is essential for expansion joints, construction joints, contraction joints, and cold joints that experience repeated cycles of opening and closing due to temperature changes, concrete creep, seismic activity, and structural loading conditions that cannot be avoided in real world engineering scenarios.

Infrastructure engineers prefer permanent leak control strips because they eliminate costly maintenance, reduce long term repair expenses, and protect reinforcement steel from corrosion that often occurs when moisture penetrates concrete and initiates rust expansion, cracking, spalling, and progressive structural degradation that compromises load bearing capacity and safety margins if left untreated, especially in foundations and below ground elements exposed to constant water pressure.

PVC water stopper systems are available in multiple profiles including center bulb, dumbbell, ribbed, flat, and labyrinth designs, each engineered to accommodate specific joint movement ranges, concrete thickness requirements, and water pressure conditions, allowing project designers and contractors to select the most appropriate configuration based on structural detailing, joint width, expected movement, and environmental exposure levels while maintaining consistent sealing reliability across large scale infrastructure projects.

Installation of professional PVC water stoppers requires proper alignment, secure fixing during concrete placement, and accurate welding of joints using heat fusion methods to create continuous leak proof connections between strip segments, ensuring that there are no weak points that could allow water passage after curing, and skilled workmanship combined with quality materials significantly enhances the long term performance of the waterproofing system in demanding construction environments.

Permanent leak control strips also support sustainability objectives by extending the service life of concrete structures, minimizing material waste from repeated repairs, reducing water damage related energy losses in underground facilities, and lowering the overall carbon footprint associated with reconstruction activities, which aligns with modern infrastructure development strategies focused on durability, resilience, and life cycle cost efficiency rather than short term solutions.

PVC water stoppers demonstrate excellent resistance to aging, ultraviolet exposure when partially exposed, microbial growth, and chemical attack from soil contaminants, sewage environments, industrial effluents, and chlorinated water systems, making them suitable for water retaining structures such as tanks, swimming pools, canals, dams, and wastewater treatment plants where hygiene, safety, and long term sealing reliability are critical performance requirements.

The flexibility of PVC material allows the water stopper to maintain intimate contact with surrounding concrete even when minor cracks develop near the joint, preventing capillary water migration that could otherwise spread moisture across structural elements and interior finishes, thereby protecting finishes, coatings, electrical systems, insulation layers, and architectural components from hidden water damage that often goes unnoticed until major repairs become unavoidable.

Professional infrastructure contractors rely on PVC water stoppers because they offer predictable performance, standardized manufacturing tolerances, compatibility with reinforced concrete design practices, and proven field history across highways, metro systems, power plants, ports, industrial facilities, and municipal infrastructure projects where safety regulations, quality assurance protocols, and long design life expectations demand materials that deliver consistent waterproof integrity under varying site conditions.

Proper storage and handling of PVC water stoppers preserve material flexibility and prevent deformation prior to installation, ensuring that strips maintain correct profile geometry and welding performance on site, while controlled temperature storage avoids excessive stiffness in cold environments or premature softening under extreme heat exposure during transportation and staging operations.

Permanent leak control strips also integrate effectively with complementary waterproofing systems such as crystalline admixtures, surface membranes, joint sealants, and protective coatings, providing layered protection strategies that enhance overall waterproof reliability in critical structures where redundancy improves risk management and long term operational continuity.

In seismic regions and high movement structures, the elastic behavior of PVC water stoppers absorbs joint displacement without transferring excessive stress to concrete edges, reducing crack propagation and maintaining water tightness even during dynamic loading events that would otherwise compromise rigid sealing materials and brittle joint fillers.

Infrastructure asset owners benefit from reduced downtime, improved asset value, lower insurance risk, and enhanced safety compliance when reliable water stopping systems prevent leaks that could disrupt operations, damage equipment, create safety hazards, or weaken structural elements in essential facilities such as hospitals, transport terminals, manufacturing plants, and data centers.

Professional PVC water stoppers are manufactured under controlled quality standards that ensure uniform thickness, consistent flexibility, accurate rib geometry, and reliable welding performance, supporting predictable site installation outcomes and long term durability even in harsh climatic conditions including extreme heat, heavy rainfall, freeze thaw cycles, and coastal humidity exposure common in many regions.

The long service life of PVC water stopper systems reduces life cycle costs by minimizing inspection frequency, repair interventions, and emergency maintenance associated with water infiltration failures, making them a cost effective investment for developers, government agencies, contractors, and infrastructure operators seeking dependable waterproofing performance across decades of operation.

Permanent leak control strips also improve construction scheduling by enabling simultaneous concrete pouring and joint sealing without requiring separate curing stages or additional surface preparation steps, accelerating project timelines while maintaining high waterproof integrity and workmanship consistency across large scale pours and segmented construction phases.

As urban development expands underground and infrastructure density increases, the demand for reliable joint waterproofing continues to grow, positioning professional PVC water stopper technology as a foundational component of resilient construction strategies that protect public safety, structural stability, and long term investment value in modern built environments.

By selecting a permanent leak control strip system backed by proven material performance, correct profile selection, skilled installation, and integrated waterproofing design, project stakeholders achieve confidence that their infrastructure assets will remain dry, durable, and structurally secure even under continuous water exposure, heavy loading conditions, and evolving environmental stresses throughout the operational lifespan of the structure.

✅ Permanent Leak Control Strip | Professional PVC Water Stopper for Infrastructure

Permanent leak control strip solutions play a vital role in modern infrastructure projects where long term water resistance determines structural durability and safety, and professional PVC water stopper systems are widely trusted because they create a continuous physical barrier inside concrete joints that blocks groundwater pressure, surface runoff, chemical seepage, and moisture migration before it can damage foundations, basements, tunnels, retaining walls, bridges, reservoirs, water treatment plants, underground parking structures, and heavy civil construction environments that demand zero leakage tolerance while maintaining flexibility under thermal movement, settlement, vibration, and load transfer forces that naturally occur in reinforced concrete structures over time.

Unlike surface coatings that rely on adhesion alone, PVC water stoppers are embedded directly into the concrete joint during pouring, allowing the strip to become an integral part of the structure itself, which ensures permanent leak control throughout the service life of the building or infrastructure facility while resisting hydrostatic pressure, soil moisture, aggressive salts, mild chemicals, and continuous wet conditions commonly found in underground and marine environments where traditional sealing materials may fail prematurely.

Professional grade PVC water stopper profiles are manufactured using high quality flexible polyvinyl chloride compounds that balance elasticity, tensile strength, tear resistance, and dimensional stability, enabling the strip to deform with joint movement without cracking, shrinking, or losing watertight integrity, which is essential for expansion joints, construction joints, contraction joints, and cold joints that experience repeated cycles of opening and closing due to temperature changes, concrete creep, seismic activity, and structural loading conditions that cannot be avoided in real world engineering scenarios.

Infrastructure engineers prefer permanent leak control strips because they eliminate costly maintenance, reduce long term repair expenses, and protect reinforcement steel from corrosion that often occurs when moisture penetrates concrete and initiates rust expansion, cracking, spalling, and progressive structural degradation that compromises load bearing capacity and safety margins if left untreated, especially in foundations and below ground elements exposed to constant water pressure.

PVC water stopper systems are available in multiple profiles including center bulb, dumbbell, ribbed, flat, and labyrinth designs, each engineered to accommodate specific joint movement ranges, concrete thickness requirements, and water pressure conditions, allowing project designers and contractors to select the most appropriate configuration based on structural detailing, joint width, expected movement, and environmental exposure levels while maintaining consistent sealing reliability across large scale infrastructure projects.

Installation of professional PVC water stoppers requires proper alignment, secure fixing during concrete placement, and accurate welding of joints using heat fusion methods to create continuous leak proof connections between strip segments, ensuring that there are no weak points that could allow water passage after curing, and skilled workmanship combined with quality materials significantly enhances the long term performance of the waterproofing system in demanding construction environments.

Permanent leak control strips also support sustainability objectives by extending the service life of concrete structures, minimizing material waste from repeated repairs, reducing water damage related energy losses in underground facilities, and lowering the overall carbon footprint associated with reconstruction activities, which aligns with modern infrastructure development strategies focused on durability, resilience, and life cycle cost efficiency rather than short term solutions.

PVC water stoppers demonstrate excellent resistance to aging, ultraviolet exposure when partially exposed, microbial growth, and chemical attack from soil contaminants, sewage environments, industrial effluents, and chlorinated water systems, making them suitable for water retaining structures such as tanks, swimming pools, canals, dams, and wastewater treatment plants where hygiene, safety, and long term sealing reliability are critical performance requirements.

The flexibility of PVC material allows the water stopper to maintain intimate contact with surrounding concrete even when minor cracks develop near the joint, preventing capillary water migration that could otherwise spread moisture across structural elements and interior finishes, thereby protecting finishes, coatings, electrical systems, insulation layers, and architectural components from hidden water damage that often goes unnoticed until major repairs become unavoidable.

Professional infrastructure contractors rely on PVC water stoppers because they offer predictable performance, standardized manufacturing tolerances, compatibility with reinforced concrete design practices, and proven field history across highways, metro systems, power plants, ports, industrial facilities, and municipal infrastructure projects where safety regulations, quality assurance protocols, and long design life expectations demand materials that deliver consistent waterproof integrity under varying site conditions.

Proper storage and handling of PVC water stoppers preserve material flexibility and prevent deformation prior to installation, ensuring that strips maintain correct profile geometry and welding performance on site, while controlled temperature storage avoids excessive stiffness in cold environments or premature softening under extreme heat exposure during transportation and staging operations.

Permanent leak control strips also integrate effectively with complementary waterproofing systems such as crystalline admixtures, surface membranes, joint sealants, and protective coatings, providing layered protection strategies that enhance overall waterproof reliability in critical structures where redundancy improves risk management and long term operational continuity.

In seismic regions and high movement structures, the elastic behavior of PVC water stoppers absorbs joint displacement without transferring excessive stress to concrete edges, reducing crack propagation and maintaining water tightness even during dynamic loading events that would otherwise compromise rigid sealing materials and brittle joint fillers.

Infrastructure asset owners benefit from reduced downtime, improved asset value, lower insurance risk, and enhanced safety compliance when reliable water stopping systems prevent leaks that could disrupt operations, damage equipment, create safety hazards, or weaken structural elements in essential facilities such as hospitals, transport terminals, manufacturing plants, and data centers.

Professional PVC water stoppers are manufactured under controlled quality standards that ensure uniform thickness, consistent flexibility, accurate rib geometry, and reliable welding performance, supporting predictable site installation outcomes and long term durability even in harsh climatic conditions including extreme heat, heavy rainfall, freeze thaw cycles, and coastal humidity exposure common in many regions.

The long service life of PVC water stopper systems reduces life cycle costs by minimizing inspection frequency, repair interventions, and emergency maintenance associated with water infiltration failures, making them a cost effective investment for developers, government agencies, contractors, and infrastructure operators seeking dependable waterproofing performance across decades of operation.

Permanent leak control strips also improve construction scheduling by enabling simultaneous concrete pouring and joint sealing without requiring separate curing stages or additional surface preparation steps, accelerating project timelines while maintaining high waterproof integrity and workmanship consistency across large scale pours and segmented construction phases.

As urban development expands underground and infrastructure density increases, the demand for reliable joint waterproofing continues to grow, positioning professional PVC water stopper technology as a foundational component of resilient construction strategies that protect public safety, structural stability, and long term investment value in modern built environments.

By selecting a permanent leak control strip system backed by proven material performance, correct profile selection, skilled installation, and integrated waterproofing design, project stakeholders achieve confidence that their infrastructure assets will remain dry, durable, and structurally secure even under continuous water exposure, heavy loading conditions, and evolving environmental stresses throughout the operational lifespan of the structure.

✅ Permanent Leak Control Strip | Professional PVC Water Stopper for Infrastructure

Permanent leak control strip solutions play a vital role in modern infrastructure projects where long term water resistance determines structural durability and safety, and professional PVC water stopper systems are widely trusted because they create a continuous physical barrier inside concrete joints that blocks groundwater pressure, surface runoff, chemical seepage, and moisture migration before it can damage foundations, basements, tunnels, retaining walls, bridges, reservoirs, water treatment plants, underground parking structures, and heavy civil construction environments that demand zero leakage tolerance while maintaining flexibility under thermal movement, settlement, vibration, and load transfer forces that naturally occur in reinforced concrete structures over time.

Unlike surface coatings that rely on adhesion alone, PVC water stoppers are embedded directly into the concrete joint during pouring, allowing the strip to become an integral part of the structure itself, which ensures permanent leak control throughout the service life of the building or infrastructure facility while resisting hydrostatic pressure, soil moisture, aggressive salts, mild chemicals, and continuous wet conditions commonly found in underground and marine environments where traditional sealing materials may fail prematurely.

Professional grade PVC water stopper profiles are manufactured using high quality flexible polyvinyl chloride compounds that balance elasticity, tensile strength, tear resistance, and dimensional stability, enabling the strip to deform with joint movement without cracking, shrinking, or losing watertight integrity, which is essential for expansion joints, construction joints, contraction joints, and cold joints that experience repeated cycles of opening and closing due to temperature changes, concrete creep, seismic activity, and structural loading conditions that cannot be avoided in real world engineering scenarios.

Infrastructure engineers prefer permanent leak control strips because they eliminate costly maintenance, reduce long term repair expenses, and protect reinforcement steel from corrosion that often occurs when moisture penetrates concrete and initiates rust expansion, cracking, spalling, and progressive structural degradation that compromises load bearing capacity and safety margins if left untreated, especially in foundations and below ground elements exposed to constant water pressure.

PVC water stopper systems are available in multiple profiles including center bulb, dumbbell, ribbed, flat, and labyrinth designs, each engineered to accommodate specific joint movement ranges, concrete thickness requirements, and water pressure conditions, allowing project designers and contractors to select the most appropriate configuration based on structural detailing, joint width, expected movement, and environmental exposure levels while maintaining consistent sealing reliability across large scale infrastructure projects.

Installation of professional PVC water stoppers requires proper alignment, secure fixing during concrete placement, and accurate welding of joints using heat fusion methods to create continuous leak proof connections between strip segments, ensuring that there are no weak points that could allow water passage after curing, and skilled workmanship combined with quality materials significantly enhances the long term performance of the waterproofing system in demanding construction environments.

Permanent leak control strips also support sustainability objectives by extending the service life of concrete structures, minimizing material waste from repeated repairs, reducing water damage related energy losses in underground facilities, and lowering the overall carbon footprint associated with reconstruction activities, which aligns with modern infrastructure development strategies focused on durability, resilience, and life cycle cost efficiency rather than short term solutions.

PVC water stoppers demonstrate excellent resistance to aging, ultraviolet exposure when partially exposed, microbial growth, and chemical attack from soil contaminants, sewage environments, industrial effluents, and chlorinated water systems, making them suitable for water retaining structures such as tanks, swimming pools, canals, dams, and wastewater treatment plants where hygiene, safety, and long term sealing reliability are critical performance requirements.

The flexibility of PVC material allows the water stopper to maintain intimate contact with surrounding concrete even when minor cracks develop near the joint, preventing capillary water migration that could otherwise spread moisture across structural elements and interior finishes, thereby protecting finishes, coatings, electrical systems, insulation layers, and architectural components from hidden water damage that often goes unnoticed until major repairs become unavoidable.

Professional infrastructure contractors rely on PVC water stoppers because they offer predictable performance, standardized manufacturing tolerances, compatibility with reinforced concrete design practices, and proven field history across highways, metro systems, power plants, ports, industrial facilities, and municipal infrastructure projects where safety regulations, quality assurance protocols, and long design life expectations demand materials that deliver consistent waterproof integrity under varying site conditions.

Proper storage and handling of PVC water stoppers preserve material flexibility and prevent deformation prior to installation, ensuring that strips maintain correct profile geometry and welding performance on site, while controlled temperature storage avoids excessive stiffness in cold environments or premature softening under extreme heat exposure during transportation and staging operations.

Permanent leak control strips also integrate effectively with complementary waterproofing systems such as crystalline admixtures, surface membranes, joint sealants, and protective coatings, providing layered protection strategies that enhance overall waterproof reliability in critical structures where redundancy improves risk management and long term operational continuity.

In seismic regions and high movement structures, the elastic behavior of PVC water stoppers absorbs joint displacement without transferring excessive stress to concrete edges, reducing crack propagation and maintaining water tightness even during dynamic loading events that would otherwise compromise rigid sealing materials and brittle joint fillers.

Infrastructure asset owners benefit from reduced downtime, improved asset value, lower insurance risk, and enhanced safety compliance when reliable water stopping systems prevent leaks that could disrupt operations, damage equipment, create safety hazards, or weaken structural elements in essential facilities such as hospitals, transport terminals, manufacturing plants, and data centers.

Professional PVC water stoppers are manufactured under controlled quality standards that ensure uniform thickness, consistent flexibility, accurate rib geometry, and reliable welding performance, supporting predictable site installation outcomes and long term durability even in harsh climatic conditions including extreme heat, heavy rainfall, freeze thaw cycles, and coastal humidity exposure common in many regions.

The long service life of PVC water stopper systems reduces life cycle costs by minimizing inspection frequency, repair interventions, and emergency maintenance associated with water infiltration failures, making them a cost effective investment for developers, government agencies, contractors, and infrastructure operators seeking dependable waterproofing performance across decades of operation.

Permanent leak control strips also improve construction scheduling by enabling simultaneous concrete pouring and joint sealing without requiring separate curing stages or additional surface preparation steps, accelerating project timelines while maintaining high waterproof integrity and workmanship consistency across large scale pours and segmented construction phases.

As urban development expands underground and infrastructure density increases, the demand for reliable joint waterproofing continues to grow, positioning professional PVC water stopper technology as a foundational component of resilient construction strategies that protect public safety, structural stability, and long term investment value in modern built environments.

By selecting a permanent leak control strip system backed by proven material performance, correct profile selection, skilled installation, and integrated waterproofing design, project stakeholders achieve confidence that their infrastructure assets will remain dry, durable, and structurally secure even under continuous water exposure, heavy loading conditions, and evolving environmental stresses throughout the operational lifespan of the structure.

🔷 Importance of Permanent Leak Control in Infrastructure

Water leakage is one of the biggest threats to concrete structures.

Uncontrolled seepage weakens foundations and shortens service life.

🔹 Why Infrastructure Requires Strong Water Stopping Systems

Large structures face constant hydrostatic pressure and environmental exposure.

Reliable joint sealing prevents structural deterioration and safety risks.

🔸 Long-Term Durability and Asset Protection

Proper water stopping protects reinforcement steel from corrosion.

It maintains concrete strength and load capacity.

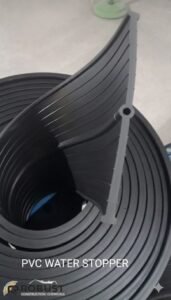

🔷 What is a Professional PVC Water Stopper

PVC water stopper is an embedded waterproof strip placed inside concrete joints.

It creates a physical barrier against water penetration.

🔹 Embedded Joint Sealing Technology

Installed during concrete pouring for permanent integration.

Eliminates surface level leakage paths.

🔸 Flexible and High-Strength PVC Material

Maintains elasticity under joint movement.

Resists tearing and deformation.

🔷 Key Features of Permanent Leak Control Strips

PVC water stoppers deliver consistent waterproof performance.

They withstand pressure and environmental stress.

🔹 Excellent Water Pressure Resistance

Prevents groundwater seepage under heavy load.

Ensures dry interiors.

🔸 Chemical and Aging Resistance

Resists salts oils and mild chemicals.

Maintains long service life.

🔷 Types of PVC Water Stopper Profiles

Different profiles serve different joint conditions.

Proper selection ensures optimal sealing.

🔹 Center Bulb and Dumbbell Profiles

Accommodate large joint movement.

Ideal for expansion joints.

🔸 Ribbed and Flat Profiles

Improve bonding with concrete.

Suitable for construction joints.

🔷 Applications in Infrastructure Projects

PVC water stoppers protect critical structures.

Used in underground and water retaining environments.

🔹 Foundations and Basements

Prevents groundwater intrusion.

Maintains structural stability.

🔸 Tunnels Bridges and Subways

Withstands vibration and pressure.

Ensures operational safety.

🔷 Use in Water Retaining Structures

Water tightness is essential for containment structures.

PVC water stoppers ensure leak prevention.

🔹 Water Tanks and Reservoirs

Prevents water loss and contamination.

Ensures hygiene.

🔸 Sewage and Treatment Plants

Resists chemical exposure.

Maintains system reliability.

🔷 Installation Process and Best Practices

Correct installation ensures maximum performance.

Attention to detail is critical.

🔹 Alignment and Fixing During Concrete Pouring

Secure positioning avoids displacement.

Ensures uniform embedment.

🔸 Heat Welding and Joint Continuity

Creates seamless connections.

Prevents weak points.

🔷 Performance Under Structural Movement

Concrete structures expand and contract naturally.

PVC water stoppers accommodate movement.

🔹 Expansion and Contraction Absorption

Maintains seal during temperature changes.

Prevents cracking.

🔸 Seismic and Vibration Resistance

Absorbs dynamic movement.

Reduces joint stress.

🔷 Compatibility with Waterproofing Systems

PVC water stoppers integrate with other systems.

Enhances overall protection.

🔹 Crystalline and Membrane Systems

Provides layered waterproofing.

Improves redundancy.

🔸 Joint Sealants and Protective Coatings

Enhances surface sealing.

Improves durability.

🔷 Advantages Over Traditional Waterproof Methods

PVC water stoppers offer permanent protection.

Reduce maintenance needs.

🔹 Long Service Life and Cost Efficiency

Minimizes repairs.

Improves return on investment.

🔸 Consistent Quality and Reliability

Standardized manufacturing ensures performance.

Reduces failure risk.

🔷 Environmental and Safety Benefits

Modern materials support sustainable construction.

Safe handling improves site conditions.

🔹 Reduced Material Waste and Repairs

Extends structure lifespan.

Minimizes resource consumption.

🔸 Safe Storage and Installation

Low risk handling.

Improves productivity.

🔷 Why Choose ROBUST PVC Water Stopper

ROBUST delivers proven construction chemical solutions.

Trusted across Pakistan infrastructure projects.

🔹 Quality Manufacturing Standards

Consistent profile accuracy.

Reliable welding performance.

🔸 Long-Term Project Value

Protects investments.

Ensures peace of mind.

🔷 Conclusion: Reliable Infrastructure Waterproof Protection

Permanent leak control ensures structural durability.

PVC water stopper delivers dependable performance.

🔹 Smart Choice for Engineers and Contractors

Supports modern construction demands.

Enhances safety.

🔸 Sustainable and Cost-Effective Solution

Reduces lifecycle costs.

Improves infrastructure resilience.

permanentpermanentpermanentpermanentpermanentpermanentpermanentpermanentpermanentpermanentpermanentpermanentpermanentpermanentpermanentpermanentpermanentpermanentpermanent