PVC – Full Technical & Commercial Details

Product Overview

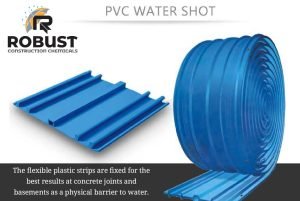

PVC

is a flexible, high-grade Polyvinyl Chloride strip designed to seal and protect concrete joints against leakage. It is installed in construction joints, expansion joints, and cold joints to prevent seepage, moisture movement, and chemical ingress. Its durable, elastic properties make it essential for basements, water tanks, retaining walls, tunnels, dams, canals, swimming pools, and all RCC structures exposed to water pressure.

Key Features

-

High-quality PVC compound

-

Excellent elongation and flexibility

-

Strong resistance to water pressure

-

UV, ozone, and chemical resistant

-

Long life and high durability

-

Easy to weld onsite

-

Suitable for both vertical and horizontal joints

-

Provides watertight sealing even under heavy load and movement

Types of PVC Waterstopper

-

Center Bulb Type

-

Ideal for expansion joints

-

Allows movement while maintaining watertightness

-

-

Flat Ribbed Type

-

Best for construction joints

-

Ensures strong bonding with concrete

-

-

Dumbbell Type

-

Used in areas with minor movement

-

Provides stable sealing

-

-

External Type (Surface Waterstop)

-

Installed on exposed surfaces

-

Suitable for rehabilitation and repair works

-

-

Base Seal Type

-

Installed directly at the base slab joint

-

Ideal for retaining walls and tanks

-

Sizes (Common Widths)

-

4 inch

-

6 inch

-

8 inch

-

9 inch

-

12 inch

(Custom sizes also available)

Applications

-

Water tanks

-

Basements

-

Lift pits

-

Dams & canals

-

Roof slabs

-

Tunnel construction

-

Retaining walls

-

Swimming pools

-

Sewage treatment plants

-

Expansion & construction joints in all RCC structures

Material Properties

-

Material: Virgin PVC

-

Hardness: 60–65 Shore A

-

Tensile Strength: High

-

Elongation: 250–300% (approx.)

-

Temperature Resistance: -20°C to 60°C

-

Chemical Resistance: Excellent against salts, mild acids, and alkalis

-

Color: Yellow / Blue / Black (as required)

Installation Method

-

Fix in formwork using clips or binding wire.

-

Ensure proper alignment at the joint.

-

Pour concrete on one side and allow initial set.

-

Pour remaining concrete ensuring full embedment of the waterstopper.

-

For long lengths, weld ends using a heating blade or welding machine.

-

Avoid folding or bending sharp corners.

Advantages

-

Prevents long-term leakage and seepage

-

Saves costly repair work

-

Improves durability of concrete structures

-

Maintains joint strength and flexibility

-

Ideal for both new construction and repairs

-

PVC – Extended Professional Details

1. Product Definition (Advanced Explanation)

PVC is a thermoplastic joint sealing profile manufactured from specially compounded Polyvinyl Chloride designed to create a continuous barrier within concrete joints. It is embedded across the joint area during concreting so that any attempting to pass through the joint is obstructed by the physical barrier of the and redirected back into the concrete mass.

Its multi-rib, bulb, and fin-shaped geometry increases the path length for water (tortuous path), ensuring maximum efficiency even under hydrostatic pressure.

2. Structural Functioning

PVC works through the following engineering mechanisms:

Hydrostatic Resistance:

The thick, ribbed structure resist infiltration even at high lateral and vertical pressure, making it suitable for underground and water-retaining structures.

Movement Absorption:

In expansion joints, the center bulb section stretches and compresses to absorb thermal, shrinkage, and structural movement while maintaining watertightness.

Crack Bridging Ability:

Due to high elongation, the bridges microcracks and prevents pathways for seepage.

Bonding Control:

Rib design increases mechanical anchorage inside concrete to avoid joint pull-out failures.

3. Detailed Types With Engineering Use

A) Center Bulb Expansion Joint Waterstopper

-

Designed for joints expected to move.

-

Center bulb prevents tearing during elongation.

-

Suitable for dams, reservoirs, long basements, bridges, and structures exposed to temperature fluctuations.

B) Dumbbell Type Construction Join

-

Reinforced outer bulbs.

-

Used in joints with minimal movement.

-

Best for water tanks, retaining walls, underground foundations.

C) Ribbed-Type

-

Increased grip for high bonding.

-

Recommended for high-rise buildings, industrial slabs, parking basements, RCC tanks.

D) External Surface

-

Installed externally using epoxy/fasteners.

-

Used for repair works or where embedding inside concrete is not possible.

-

Ideal for old leaking tanks, treatment plants, and rehabilitation jobs.

E) Kicker / Base Seal Type

-

Installed at slab-wall interface.

-

Ensures watertightness at the most critical leakage point.

-

Common in retaining walls, water tanks, and basement walls.

4. Standard Widths, Thickness & Profile Specs

Widths Available

-

100mm (4”)

-

150mm (6”)

-

200mm (8”)

-

225mm (9”)

-

300mm (12”)

Thickness

-

4mm

-

5mm

-

6mm

-

Heavy-duty 8–10mm (for dams & reservoirs)

Length

-

Standard roll: 15 meters or 20 meters

-

Custom lengths available

5. Technical Properties (Deep Detail)

Property Typical Value Purpose Hardness 60–65 Shore A Optimal flexibility + toughness Tensile Strength 12–15 MPa Withstands joint stress Elongation at Break 250–350% Prevents tearing at joints Water Absorption <0.15% Ensures no swelling/softening Service Temperature -20°C to +60°C Suitable for Pakistan climate Chemical Resistance Excellent Resists salts, chlorine, mild acids UV Stability High Suitable for exposed areas Weathering Resistance Strong Long service life

6. Installation — Deep Practical Guidance

Before Concreting

-

Store flat, not folded.

-

Fix with brass eyelets, steel clamps, or tying wires.

-

Ensure perfect centering inside joint.

-

Avoid nail penetration through the sealing section.

During Concreting

-

Place concrete carefully to avoid honeycombing around ribs.

-

Use poker vibrators near waterstop (but do not touch it).

-

Do not allow displacement of the waterstop.

Welding Joints

PVC joints must be heat welded, not glued.

Types of welds:

-

Straight Butt Joint

-

T-Joint

-

L-Joint

-

Cross Joint

Use a thermostatically controlled welding blade.

Ensure molten ends fuse completely to maintain watertight continuity.

7. Common Failures (And How to Avoid Them)

Failure 1: Incorrect placement

→ Use proper fixing clamps to hold waterstop in position.Failure 2: Poor welding

→ Only heat welding should be used; improper fusion causes leaks.Failure 3: Honeycombing

→ Ensure proper compaction around the ribs.Failure 4: Using cheap recycled PVC

→ Causes brittleness and cracking.Failure 5: Folding / kinking during installation

→ Always store waterstop in straight or coiled form without sharp bends.

8. Advantages (Commercial + Technical)

-

100% watertight joint protection

-

Long service life (20+ years)

-

Flexible & elastic under stress

-

High chemical and weather resistance

-

Suitable for all RCC structures

-

Cost-effective long-term waterproofing solution

-

Eliminates leakage repairs

-

Enhances structure durability

9. Where to Use (Advanced List)

-

Basements (retaining walls, foundation slabs)

-

Underground parking

-

Water tanks (drinking water & industrial)

-

Sewerage & STP plants

-

Dams, barrages & canals

-

Tunnels & culverts

-

Lift pits

-

Pile caps & raft foundations

-

Swimming pools

-

Expansion & construction joints

-

Hydro & irrigation projects

-

Industrial chemical tanks

10. Buyer Questions & Answers (Professional Sales Support)

Q1: Which type should be used for expansion joints?

✔ Center Bulb Type

Q2: Which type is best for construction joints?

✔ Dumbbell or Ribbed Type

Q3: How to ensure proper installation?

✔ Use correct fixing method + correct welding + proper concrete compaction.

Q4: Can PVC waterstop be installed in existing structures?

✔ Yes, with External Surface Type waterstop.

Q5: Does color affect quality?

✔ No — only material composition matters. Yellow, blue, or black all perform same when made from virgin PVC.

-

-

Ultra-Detailed PVC Description (Advanced Professional Version)

PVC is a premium-grade joint sealing barrier manufactured from specially formulated Polyvinyl Chloride designed to provide unmatched performance in concrete structures exposed to continuous or intermittent water pressure.

-

Engineered with flexible, high-elasticity compounds, it forms a permanent, integral seal within concrete joints, preventing , moisture, and chemical ingress that can compromise structural durability.

-

Its unique ribbed, bulb, and fin geometries create a multi-level defense system that blocks pathways, absorbs structural movement, and ensures uniform bonding with concrete across both vertical and horizontal joints.

PVC functions as a critical protective element in all retaining and -excluding structures such as basements, water tanks, tunnels, dams, retaining walls, culverts, foundations, and sewerage treatment facilities.

-

Embedded during the initial stages of concreting, it acts as a flexible gasket, ensuring that natural movements—caused by temperature variation, shrinkage, settlement, and load transfer—do not lead to leakage.

-

Its design creates a tortuous path that forces to travel through multiple obstacles, dramatically increasing resistance to seepage and maintaining watertight integrity even under high hydrostatic pressure.

The product’s high tensile strength, superior elongation capacity, and excellent chemical resistance make it the preferred choice for engineers, contractors, and professionals.

-

Unlike inferior recycled PVC s, high-quality virgin PVC maintains elasticity over time without cracking, hardening, shrinking, or deforming.

-

It also resists attack from salts, mild acids, alkalis, wastewater chemicals, and chlorinated—making it ideal for both potable and industrial applications.

-

The material’s UV and ozone stability allow installation in exposed areas without degradation.

PVC is available in multiple profiles—center bulb, dumbbell, ribbed, base-seal, and external surface types—each designed to meet specific structural requirements.

-

Center bulb profiles are ideal for expansion joints requiring movement absorption, while dumbbell and ribbed profiles are optimized for construction joints with minimal movement.

-

Base-seal types are designed for slab-to-wall joints, and external types are perfect for repair works where internal embedding is not possible.

-

Every profile is engineered to provide maximum anchorage, mechanical grip, and seamless integration with concrete.

During installation, PVC is carefully positioned at the center of the joint using metal eyelets, clamps, or wires to ensure proper alignment.

-

The ends are joined using heat welding, ensuring complete fusion for a leak-proof, continuous length.

-

Proper concrete compaction around the ribs is essential to eliminate voids that could compromise performance.

-

When installed correctly, PVC can protect structures for decades, eliminating maintenance costs and preventing serious structural deterioration caused by seepage.

In modern construction, where long-term durability and watertight performance are essential, PVC stands as a fundamental component that ensures safety, quality, and structural service life.

-

It provides long-lasting, reliable joint sealing that enhances overall concrete performance, prevents leakage-related failures, and meets the stringent requirements of large-scale commercial, industrial, and civil engineering projects.

-

1. Introduction to PVC Waterstopper

PVC is an advanced joint sealing component designed to protect reinforced concrete structures from water passage, fluid migration, and moisture penetration.

-

Manufactured from specially engineered Polyvinyl Chloride, it offers exceptional flexibility, high tensile strength, and long-term durability, making it one of the most reliable elements used in modern construction.

-

PVC acts as a physical barrier that blocks the entry of water at concrete joints, which are the most vulnerable points in any RCC structure.

-

Whether the structure needs to retain water, exclude water, or resist intense hydrostatic pressure, PVC Waterstopper is an essential safety component.

2. The Critical Role of in Concrete Engineering

Concrete, despite being extremely strong, contains joints and cracks due to shrinkage, thermal expansion, structural settlement, and design-based segmentation.

-

These joints become potential leakage paths. In -retaining or -excluding structures, joints must be protected, otherwise will penetrate, leading to structural damage, reinforcement corrosion, mold formation, and a reduction in structural life.

-

PVC eliminates this risk by creating a continuous, flexible,seal that works through a combination of mechanical anchorage, hydrostatic resistance, and crack bridging ability.3. Material Composition and Scientific Formulation

PVC is made using a high-grade thermoplastic polymer blended with plasticizers, stabilizers, and additives that enhance its performance.

-

The formulation is carefully designed to achieve the ideal balance between hardness, elongation, flexibility, and durability.

-

Virgin PVC granules are used to ensure long-term structural stability.

Key additives include:-

Plasticizers for high elasticity

-

UV stabilizers to prevent degradation in sunlight

-

Heat stabilizers to maintain dimensional stability

-

Impact modifiers for bending and torsion resistance

-

Color pigments for identification and quality control

This engineered formulation ensures that PVC does not crack, tear, shrink, harden, or deform over time even in harsh environmental conditions.

4. Engineering Principle Behind PVC Function

PVC functions using three fundamental engineering mechanisms:

A. Hydrostatic Pressure Resistance

under pressure attempts to move through paths of least resistance. The multiple ribs, bulbs, and fins of the create a complicated “tortuous path,” slowing down and blocking flow. This dramatically increases resistance to seepage.

B. Movement Absorption

Concrete expands and contracts. Expansion joints experience cyclic movement that can cause leakage. PVC , especially those with center bulbs, absorbs these movements while maintaining watertight performance.

C. Mechanical Interlocking with Concrete

Ribs along the profile anchor the securely inside the concrete. This prevents displacement, pull-out, or failure.

5. Manufacturing Process – Advanced Production Details

PVC is produced through a high-precision extrusion process.

Key steps include:-

Material blending – Formulated compounds are mixed to exact ratios.

-

Extrusion – Melted PVC passes through specialized steel dies that shape it into specific profiles.

-

Cooling – The extruded profile is cooled to maintain dimensional accuracy.

-

Quality trimming – Edges and surfaces are aligned for consistency.

-

Coiling & curing – Rolls are coiled and kept for stress relaxation.

-

Welding tests – Samples undergo heat-weld testing to ensure fusion capability.

High extrusion accuracy ensures that every rib, bulb, and fin is perfectly formed to function under real structural loads.

6. Types of PVC and Their Detailed Applications

A. Center Bulb Expansion Joint Waterstopper

-

Contains a large central bulb

-

Designed for joints with significant movement

-

Used in dams, reservoirs, long basement corridors, bridges

-

Allows movement while maintaining a watertight seal

B. Dumbbell Construction Joint

-

Used in non-moving joints

-

Provides excellent anchorage

-

Ideal fortanks, foundations, retaining walls

C. Ribbed Type Waterstopper

-

Heavy ribs for strong bonding

-

Increased hydrostatic resistance

-

Suitable for structural slabs, tunnels, industrial floors

D. Base Seal / Kicker Type

-

Installed at slab-wall joints

-

Protects the most vulnerable leakage point

-

Used in basements, retaining walls

E. External Surface Fixed outside the structure

-

Ideal for old structures and repair work

-

Applied using adhesive or fastening tools

Each type is manufactured to serve a specific engineering function and is selected based on joint type, movement nature, hydrostatic pressure level, and structural design.

7. Dimensions and Mechanical Properties

PVC comes in multiple sizes to meet diverse project requirements.

Width

-

4 inch (100mm)

-

6 inch (150mm)

-

8 inch (200mm)

-

9 inch (225mm)

-

12 inch (300mm)

Thickness

-

Standard 4–6mm

-

Heavy-duty 8–10mm for high-pressure zones

Mechanical Characteristics

-

Elongation: 250–350%

-

Hardness: 60–65 Shore A

-

Tensile Strength: 12–15 MPa

-

Water Absorption: < 0.15%

-

Temperature Resistance: -20°C to +60°C

-

Chemical Resistance: Excellent against salts, mild acids, alkalines

-

Weathering Resistance: High UV stability

These properties ensure that PVC remains effective even in extreme working environments.

8. Installation Science – Complete Advanced Practical Guide

A. Before Installation

-

Ensure quality of the waterstopper

-

Store coils flat or hanging to avoid bends

-

Cut to required lengths using a heated knife

-

Check all formwork alignments

B. Fixing the Waterstop

-

Use steel clamps, eyelets, nails on flanges (not sealing zones)

-

Ensure perfect centering inside the joint

-

Leave enough room for movement in expansion joints

C. Welding

Welding is the most critical step for long lengths. Ends are joined by:

-

Butt weld

-

T-weld

-

L-weld

-

Cross weld

The welding blade temperature must be controlled to avoid burning or under-heating the PVC.

D. During Concreting

-

Pour concrete slowly

-

Use vibrators carefully without touching the

-

Avoid voids around ribs

-

Check for displacement

E. Common Mistakes to Avoid

-

Using adhesive instead of welding

-

Nailing through sealing zones

-

Insufficient compaction

-

Poor welding quality

Proper installation ensures decades of performance.

9. Where PVC Is Used – Extensive Project Applications

PVC is used in:

Water-retaining Structures

-

Water tanks

-

Reservoirs

-

Swimming pools

-

Water treatment plants

-

Irrigation channels

Underground Structures

-

Basements

-

Parking structures

-

Underground tunnels

-

Subways

-

Lift pits

Civil Engineering Projects

-

Dams

-

Barrages

-

Canals

-

Culverts

-

Bridge decks

Industrial Projects

-

Chemical tanks

-

STP units

-

Industrial pipelines

-

Retaining walls for factories

Commercial & Residential Structures

-

High-rise towers

-

Foundations

-

Pile caps

-

Raft slabs

Its versatility makes it indispensable in almost every RCC structure.

10. Long-Term Performance and Durability Characteristics

PVC is designed for long life with:

-

Resistance to weather

-

High elasticity

-

No cracking or hardening

-

Excellent performance under pressure

-

Resistance to chemical contamination

Concrete structures protected with PVC remain more durable and require fewer maintenance operations over their lifespan.

11. Comparison with Other Materials

PVC vs Rubber

-

PVC more economical

-

Rubber more elastic but expensive

-

PVC preferred for general infrastructure

PVC vs HDPE Waterstop

-

PVC more flexible

-

HDPE stiffer but durable

-

PVC easier to install and weld

PVC vs Bentonite Waterstop

-

Bentonite swells; PVC provides physical barrier

-

PVC works in both positive & negative pressure

-

PVC more reliable for long run

PVC offers the perfect balance between price, performance, and installation convenience.

12. Expected Service Life

When installed correctly, PVC can last over 25–30 years or even longer depending on environmental and structural conditions. Its chemical and weather resistance ensure long-term protection with minimal maintenance.

13. Advantages in Modern Construction

-

Strong waterproofing performance

-

Flexibility under load

-

Resistance to chemicals, UV, and weather

-

Easy welding and installation

-

Long-term cost savings

-

Suitable for all types of RCC structures

-

Reliable under hydrostatic pressure

PVC Waterstopper helps improve structural lifespan and integrity, making it essential for large civil engineering and commercial projects.

14. Why Engineers Prefer PVC Waterstopper

Engineers choose because:

-

It provides guaranteed joint waterproofing

-

Compatible with most concrete mix designs

-

Complies with international construction standards

-

Requires minimal maintenance

-

Performs uniformly in all climates

PVC ensures that structures remain dry, safe, and protected.

15. Quality Testing and Compliance Standards

Standard tests include:

-

Tensile strength

-

Shore hardness

-

Elongation

-

Water absorption

-

Dimensional stability

-

Welding strength

Compliance with ASTM, BS, and EN standards ensures product quality.

16. Economic Benefits

-

Reduces future leakage repair costs

-

Protects reinforcement from corrosion

-

Extends structural lifespan

-

Minimizes downtime in industrial facilities

Investing in quality PVC is far cheaper than repairing water-damaged concrete.

17. Conclusion

PVC Waterstopper is more than a simple waterproofing accessory—it is a critical structural component engineered to deliver maximum protection at the most vulnerable points of any concrete structure.

-

-

With its high flexibility, durability, chemical resistance, and excellent performance under pressure, ensures long-lasting watertight integrity, making it a preferred choice for engineers, contractors, and construction professionals worldwide.

-

High-Quality PVC Water Stopper | Long-Lasting Waterproofing for Expansion & Construction Joints in karachi

PVC Waterstopper is a durable, high-quality PVC joint sealing strip designed to prevent leakage in concrete structures.