✅ Seamless Protective Membrane | High-Strength Sheet for Roofs & Walls

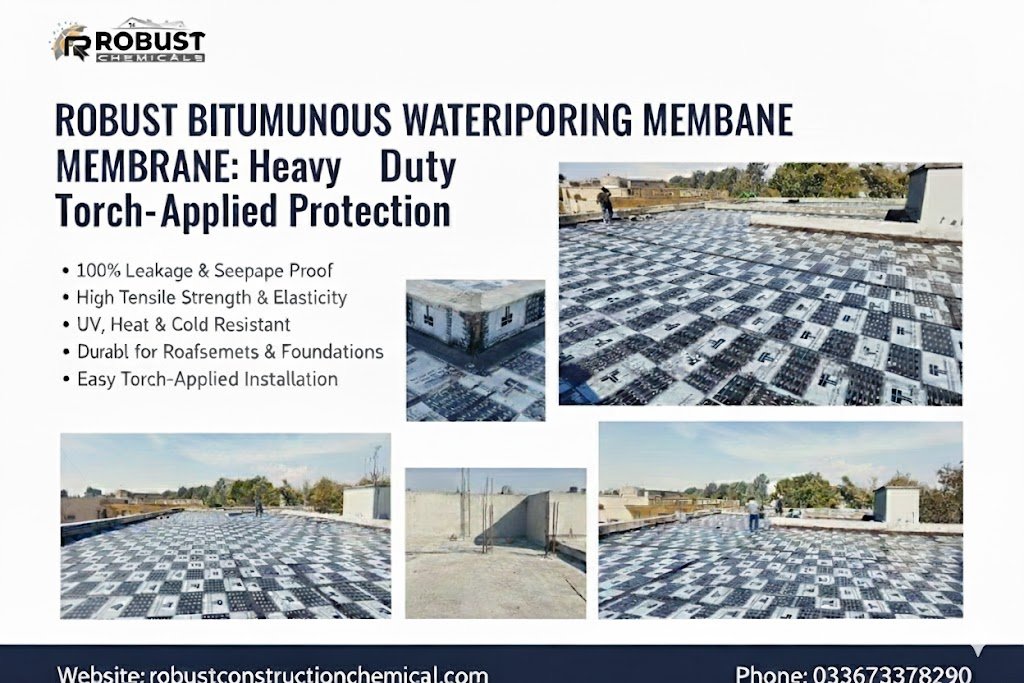

Seamless protective membranes are an essential component for modern construction, ensuring that roofs, walls, and concrete surfaces remain safe from water infiltration and environmental damage. . High-strength membrane sheets provide a continuous barrier that prevents leaks, reduces moisture penetration, and enhances the longevity of structural elements in both residential and commercial projects. .

These membranes are designed to be flexible and durable, accommodating natural movement in buildings caused by temperature fluctuations, vibrations, or settling. . Unlike rigid waterproof layers, seamless sheets stretch and conform to surface irregularities, maintaining protection without cracking or peeling over time. .

The material is engineered for strong adhesion to a variety of surfaces, including concrete, masonry, metal, and pre-coated areas. . This ensures that critical points, such as joints, corners, and penetrations, remain sealed and secure, eliminating weak points where water could infiltrate. .

Seamless protective membranes also resist environmental and chemical exposure. . They perform exceptionally well under rain, UV radiation, temperature extremes, and mild chemical contact, making them suitable for urban and industrial environments. .

Application is straightforward and efficient. . Membrane sheets can be rolled or laid over prepared surfaces, forming a continuous barrier that requires minimal seams and reduces installation errors, saving time and labor costs. .

These membranes improve the durability and performance of roofs and walls. . By preventing water penetration and limiting surface degradation, they reduce maintenance requirements and protect finishes from early deterioration, which is especially important for high-value properties and infrastructure projects. .

High-strength sheets are suitable for multiple areas, including residential rooftops, commercial buildings, industrial warehouses, terraces, balconies, basements, water tanks, and retaining walls. . Their versatility ensures comprehensive protection against leaks, dampness, and environmental wear across all critical surfaces. .

The membranes enhance thermal efficiency by preventing moisture accumulation that can compromise insulation and indoor comfort. . Buildings with properly installed membranes experience reduced energy consumption and improved indoor environmental quality. .

Durability under harsh weather is a key advantage. . Seamless sheets resist heavy rainfall, wind, temperature changes, and prolonged sun exposure, providing reliable long-term performance even in challenging climates. .

Proper surface preparation is crucial. . Surfaces must be clean, dry, and free from dust, oils, and loose particles, and any cracks or voids should be repaired to ensure maximum adhesion and continuous protection. .

The seamless design ensures complete coverage around complex areas such as drains, pipe penetrations, and structural corners. . These zones are often prone to leakage, and the flexible sheet creates a continuous, watertight seal. .

Membrane sheets are environmentally friendly, with low VOC emissions and safe handling during application. . This makes them suitable for both indoor and outdoor use without compromising safety or environmental compliance. .

Contractors benefit from the efficiency of membrane sheet installation. . The sheets are easy to handle, require minimal labor, and can be applied quickly over large areas, providing immediate waterproof protection that lasts for years. .

Industrial facilities see the advantage in abrasion and mechanical resistance. . Even under foot traffic, equipment movement, and maintenance activity, the membrane maintains integrity and continues to provide superior protection. .

The membrane is compatible with other construction materials such as cementitious coatings, insulation layers, drainage systems, and reflective surfaces. . This allows layered protection strategies to enhance safety and performance in critical structures. .

Routine inspection and minor touch-ups extend the lifespan of the membrane. . Damaged areas can be easily repaired or recoated without removing the entire sheet, maintaining continuous waterproofing and structural integrity. .

Seamless protective membranes play a vital role in protecting buildings from long-term water damage, structural deterioration, and costly repairs. . Their advanced formulation, ease of application, and high performance make them a preferred solution for modern construction projects seeking reliable waterproofing. .

Choosing high-strength membrane sheets ensures property owners and contractors gain a durable, cost-effective solution that safeguards structural integrity, reduces maintenance costs, and enhances the lifespan of roofs, walls, and concrete surfaces.

✅ Seamless Protective Membrane | High-Strength Sheet for Roofs & Walls

Seamless protective membranes are an essential component for modern construction, ensuring that roofs, walls, and concrete surfaces remain safe from water infiltration and environmental damage. . High-strength membrane sheets provide a continuous barrier that prevents leaks, reduces moisture penetration, and enhances the longevity of structural elements in both residential and commercial projects. .

These membranes are designed to be flexible and durable, accommodating natural movement in buildings caused by temperature fluctuations, vibrations, or settling. . Unlike rigid waterproof layers, seamless sheets stretch and conform to surface irregularities, maintaining protection without cracking or peeling over time. .

The material is engineered for strong adhesion to a variety of surfaces, including concrete, masonry, metal, and pre-coated areas. . This ensures that critical points, such as joints, corners, and penetrations, remain sealed and secure, eliminating weak points where water could infiltrate. .

Seamless protective membranes also resist environmental and chemical exposure. . They perform exceptionally well under rain, UV radiation, temperature extremes, and mild chemical contact, making them suitable for urban and industrial environments. .

Application is straightforward and efficient. . Membrane sheets can be rolled or laid over prepared surfaces, forming a continuous barrier that requires minimal seams and reduces installation errors, saving time and labor costs. .

These membranes improve the durability and performance of roofs and walls. . By preventing water penetration and limiting surface degradation, they reduce maintenance requirements and protect finishes from early deterioration, which is especially important for high-value properties and infrastructure projects. .

High-strength sheets are suitable for multiple areas, including residential rooftops, commercial buildings, industrial warehouses, terraces, balconies, basements, water tanks, and retaining walls. . Their versatility ensures comprehensive protection against leaks, dampness, and environmental wear across all critical surfaces. .

The membranes enhance thermal efficiency by preventing moisture accumulation that can compromise insulation and indoor comfort. . Buildings with properly installed membranes experience reduced energy consumption and improved indoor environmental quality. .

Durability under harsh weather is a key advantage. . Seamless sheets resist heavy rainfall, wind, temperature changes, and prolonged sun exposure, providing reliable long-term performance even in challenging climates. .

Proper surface preparation is crucial. . Surfaces must be clean, dry, and free from dust, oils, and loose particles, and any cracks or voids should be repaired to ensure maximum adhesion and continuous protection. .

The seamless design ensures complete coverage around complex areas such as drains, pipe penetrations, and structural corners. . These zones are often prone to leakage, and the flexible sheet creates a continuous, watertight seal. .

Membrane sheets are environmentally friendly, with low VOC emissions and safe handling during application. . This makes them suitable for both indoor and outdoor use without compromising safety or environmental compliance. .

Contractors benefit from the efficiency of membrane sheet installation. . The sheets are easy to handle, require minimal labor, and can be applied quickly over large areas, providing immediate waterproof protection that lasts for years. .

Industrial facilities see the advantage in abrasion and mechanical resistance. . Even under foot traffic, equipment movement, and maintenance activity, the membrane maintains integrity and continues to provide superior protection. .

The membrane is compatible with other construction materials such as cementitious coatings, insulation layers, drainage systems, and reflective surfaces. . This allows layered protection strategies to enhance safety and performance in critical structures. .

Routine inspection and minor touch-ups extend the lifespan of the membrane. . Damaged areas can be easily repaired or recoated without removing the entire sheet, maintaining continuous waterproofing and structural integrity. .

Seamless protective membranes play a vital role in protecting buildings from long-term water damage, structural deterioration, and costly repairs. . Their advanced formulation, ease of application, and high performance make them a preferred solution for modern construction projects seeking reliable waterproofing. .

Choosing high-strength membrane sheets ensures property owners and contractors gain a durable, cost-effective solution that safeguards structural integrity, reduces maintenance costs, and enhances the lifespan of roofs, walls, and concrete surfaces.

✅ Seamless Protective Membrane | High-Strength Sheet for Roofs & Walls

Seamless protective membranes are an essential component for modern construction, ensuring that roofs, walls, and concrete surfaces remain safe from water infiltration and environmental damage. . High-strength membrane sheets provide a continuous barrier that prevents leaks, reduces moisture penetration, and enhances the longevity of structural elements in both residential and commercial projects. .

These membranes are designed to be flexible and durable, accommodating natural movement in buildings caused by temperature fluctuations, vibrations, or settling. . Unlike rigid waterproof layers, seamless sheets stretch and conform to surface irregularities, maintaining protection without cracking or peeling over time. .

The material is engineered for strong adhesion to a variety of surfaces, including concrete, masonry, metal, and pre-coated areas. . This ensures that critical points, such as joints, corners, and penetrations, remain sealed and secure, eliminating weak points where water could infiltrate. .

Seamless protective membranes also resist environmental and chemical exposure. . They perform exceptionally well under rain, UV radiation, temperature extremes, and mild chemical contact, making them suitable for urban and industrial environments. .

Application is straightforward and efficient. . Membrane sheets can be rolled or laid over prepared surfaces, forming a continuous barrier that requires minimal seams and reduces installation errors, saving time and labor costs. .

These membranes improve the durability and performance of roofs and walls. . By preventing water penetration and limiting surface degradation, they reduce maintenance requirements and protect finishes from early deterioration, which is especially important for high-value properties and infrastructure projects. .

High-strength sheets are suitable for multiple areas, including residential rooftops, commercial buildings, industrial warehouses, terraces, balconies, basements, water tanks, and retaining walls. . Their versatility ensures comprehensive protection against leaks, dampness, and environmental wear across all critical surfaces. .

The membranes enhance thermal efficiency by preventing moisture accumulation that can compromise insulation and indoor comfort. . Buildings with properly installed membranes experience reduced energy consumption and improved indoor environmental quality. .

Durability under harsh weather is a key advantage. . Seamless sheets resist heavy rainfall, wind, temperature changes, and prolonged sun exposure, providing reliable long-term performance even in challenging climates. .

Proper surface preparation is crucial. . Surfaces must be clean, dry, and free from dust, oils, and loose particles, and any cracks or voids should be repaired to ensure maximum adhesion and continuous protection. .

The seamless design ensures complete coverage around complex areas such as drains, pipe penetrations, and structural corners. . These zones are often prone to leakage, and the flexible sheet creates a continuous, watertight seal. .

Membrane sheets are environmentally friendly, with low VOC emissions and safe handling during application. . This makes them suitable for both indoor and outdoor use without compromising safety or environmental compliance. .

Contractors benefit from the efficiency of membrane sheet installation. . The sheets are easy to handle, require minimal labor, and can be applied quickly over large areas, providing immediate waterproof protection that lasts for years. .

Industrial facilities see the advantage in abrasion and mechanical resistance. . Even under foot traffic, equipment movement, and maintenance activity, the membrane maintains integrity and continues to provide superior protection. .

The membrane is compatible with other construction materials such as cementitious coatings, insulation layers, drainage systems, and reflective surfaces. . This allows layered protection strategies to enhance safety and performance in critical structures. .

Routine inspection and minor touch-ups extend the lifespan of the membrane. . Damaged areas can be easily repaired or recoated without removing the entire sheet, maintaining continuous waterproofing and structural integrity. .

Seamless protective membranes play a vital role in protecting buildings from long-term water damage, structural deterioration, and costly repairs. . Their advanced formulation, ease of application, and high performance make them a preferred solution for modern construction projects seeking reliable waterproofing. .

Choosing high-strength membrane sheets ensures property owners and contractors gain a durable, cost-effective solution that safeguards structural integrity, reduces maintenance costs, and enhances the lifespan of roofs, walls, and concrete surfaces.

✅ Seamless Protective Membrane | High-Strength Sheet for Roofs & Walls

Seamless protective membranes are an essential component for modern construction, ensuring that roofs, walls, and concrete surfaces remain safe from water infiltration and environmental damage. . High-strength membrane sheets provide a continuous barrier that prevents leaks, reduces moisture penetration, and enhances the longevity of structural elements in both residential and commercial projects. .

These membranes are designed to be flexible and durable, accommodating natural movement in buildings caused by temperature fluctuations, vibrations, or settling. . Unlike rigid waterproof layers, seamless sheets stretch and conform to surface irregularities, maintaining protection without cracking or peeling over time. .

The material is engineered for strong adhesion to a variety of surfaces, including concrete, masonry, metal, and pre-coated areas. . This ensures that critical points, such as joints, corners, and penetrations, remain sealed and secure, eliminating weak points where water could infiltrate. .

Seamless protective membranes also resist environmental and chemical exposure. . They perform exceptionally well under rain, UV radiation, temperature extremes, and mild chemical contact, making them suitable for urban and industrial environments. .

Application is straightforward and efficient. . Membrane sheets can be rolled or laid over prepared surfaces, forming a continuous barrier that requires minimal seams and reduces installation errors, saving time and labor costs. .

These membranes improve the durability and performance of roofs and walls. . By preventing water penetration and limiting surface degradation, they reduce maintenance requirements and protect finishes from early deterioration, which is especially important for high-value properties and infrastructure projects. .

High-strength sheets are suitable for multiple areas, including residential rooftops, commercial buildings, industrial warehouses, terraces, balconies, basements, water tanks, and retaining walls. . Their versatility ensures comprehensive protection against leaks, dampness, and environmental wear across all critical surfaces. .

The membranes enhance thermal efficiency by preventing moisture accumulation that can compromise insulation and indoor comfort. . Buildings with properly installed membranes experience reduced energy consumption and improved indoor environmental quality. .

Durability under harsh weather is a key advantage. . Seamless sheets resist heavy rainfall, wind, temperature changes, and prolonged sun exposure, providing reliable long-term performance even in challenging climates. .

Proper surface preparation is crucial. . Surfaces must be clean, dry, and free from dust, oils, and loose particles, and any cracks or voids should be repaired to ensure maximum adhesion and continuous protection. .

The seamless design ensures complete coverage around complex areas such as drains, pipe penetrations, and structural corners. . These zones are often prone to leakage, and the flexible sheet creates a continuous, watertight seal. .

Membrane sheets are environmentally friendly, with low VOC emissions and safe handling during application. . This makes them suitable for both indoor and outdoor use without compromising safety or environmental compliance. .

Contractors benefit from the efficiency of membrane sheet installation. . The sheets are easy to handle, require minimal labor, and can be applied quickly over large areas, providing immediate waterproof protection that lasts for years. .

Industrial facilities see the advantage in abrasion and mechanical resistance. . Even under foot traffic, equipment movement, and maintenance activity, the membrane maintains integrity and continues to provide superior protection. .

The membrane is compatible with other construction materials such as cementitious coatings, insulation layers, drainage systems, and reflective surfaces. . This allows layered protection strategies to enhance safety and performance in critical structures. .

Routine inspection and minor touch-ups extend the lifespan of the membrane. . Damaged areas can be easily repaired or recoated without removing the entire sheet, maintaining continuous waterproofing and structural integrity. .

Seamless protective membranes play a vital role in protecting buildings from long-term water damage, structural deterioration, and costly repairs. . Their advanced formulation, ease of application, and high performance make them a preferred solution for modern construction projects seeking reliable waterproofing. .

Choosing high-strength membrane sheets ensures property owners and contractors gain a durable, cost-effective solution that safeguards structural integrity, reduces maintenance costs, and enhances the lifespan of roofs, walls, and concrete surfaces.

🔶 H2: What Is Seamless Protective Membrane

🔹 H3: Overview of High-Strength Waterproof Sheets

🔸 H4: Composition and Material Properties

🔸 H4: How It Works on Roofs and Walls

🔹 H3: Key Advantages of Membrane Sheets

🔸 H4: Flexibility and Crack Resistance

🔸 H4: Long-Term Durability and Protection

🔶 H2: Benefits of Using Membrane Sheets

🔹 H3: Water and Moisture Resistance

🔸 H4: Roof Applications

🔸 H4: Wall and Basement Protection

🔹 H3: Durability Under Harsh Conditions

🔸 H4: UV and Sunlight Resistance

🔸 H4: Chemical and Pollution Protection

🔶 H2: Application Areas

🔹 H3: Residential Buildings

🔸 H4: Roofs, Balconies, and Terraces

🔸 H4: Basements and Retaining Walls

🔹 H3: Commercial and Industrial Sites

🔸 H4: Warehouses and Factories

🔸 H4: Bridges, Roads, and Infrastructure Projects

🔶 H2: Installation Process

🔹 H3: Surface Preparation

🔸 H4: Cleaning and Crack Repair

🔸 H4: Ensuring Dry and Stable Substrate

🔹 H3: Membrane Sheet Application

🔸 H4: Rolling, Laying, and Seam Management

🔸 H4: Layer Thickness and Coverage Tips

🔶 H2: Maintenance and Longevity

🔹 H3: Routine Inspection

🔸 H4: Detecting Minor Damages

🔸 H4: Recoating and Repair Guidelines

🔹 H3: Extending Membrane Life

🔸 H4: Proper Care of Roofs and Walls

🔸 H4: Protecting from Environmental Stress

protectiveprotectiveprotectiveprotectiveprotectiveprotectiveprotectiveprotectiveprotectiveprotectiveprotectiveprotectiveprotectiveprotectiveprotectiveprotectiveprotectiveprotectiveprotectiveprotectiveprotectiveprotective