Swell Bar is an advanced hydrophilic waterstop designed to provide leak-free protection for concrete structures, ensuring complete waterproofing and long-term structural stability.

Its high-performance formulation expands on contact with water, filling construction joints, expansion joints, contraction joints, and cold joints, creating a continuous, reliable barrier against water infiltration.

This innovative solution is widely used in dams, tunnels, basements, water tanks, retaining walls, canals, and other critical concrete structures where waterproofing is essential for durability and safety.

The advanced hydrophilic properties of Swell Bar allow it to absorb moisture and swell up to several times.

its original volume, forming a tight seal in concrete joints that prevents seepage, leakage, and dampness. Its flexibility accommodates minor movements, cracks, and structural shifts while maintaining a watertight barrier.

making it ideal for high-value construction projects where permanent protection is required. Contractors, engineers, and builders rely on Swell Bar for its exceptional performance, ease of installation, and long-term reliability.

Swell Bar is made from high-quality elastomeric hydrophilic material, ensuring chemical resistance, durability, and long-lasting performance even under extreme environmental conditions.

It can resist groundwater pressure, hydrostatic stress, and aggressive chemicals, making it suitable for industrial, commercial, and residential applications. Its unique design and high swelling capacity guarantee effective sealing of joints in concrete, preventing water-related damage such as reinforcement corrosion, concrete spalling, mold growth, and structural weakening.

The waterstop is easy to install, making it convenient for contractors and construction teams. It can be embedded in fresh concrete during pouring or retrofitted in existing joints with proper surface preparation, offering versatile solutions for both new constructions and renovation projects.

Its adhesive backing or mechanical fixing ensures firm placement, and once concrete is poured, Swell Bar integrates seamlessly into the structure, creating a permanent watertight joint.

Swell Bar provides exceptional performance in dams and water-retaining structures where water pressure is high.

Its ability to expand in contact with water prevents seepage through construction and expansion joints, maintaining water levels, structural stability, and operational efficiency. Similarly, in tunnels, basements, canals, and retaining walls, it ensures dry, safe, and durable structures, protecting interiors, reinforcement, and finishes from water damage.

The hydrophilic waterstop also improves the longevity of concrete structures by reducing water penetration, which can cause corrosion, cracking, and weakening of the material.

By preventing water ingress, Swell Bar protects plaster, tiles, flooring, and other finishes, ensuring interiors remain dry, safe, and hygienic. It is ideal for high-rise buildings, industrial facilities, residential complexes, hospitals, schools, and commercial projects that require permanent waterproofing solutions.

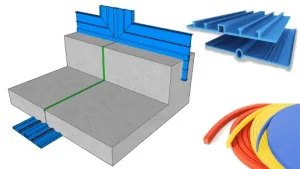

Swell Bar is available in various profiles, widths, and thicknesses to suit different joint sizes and types. Central bulb, dumbbell.

trapezoidal, and other specialized profiles allow precise installation in expansion joints, construction joints, and contraction joints, maximizing the sealing efficiency and performance. Its flexibility ensures that it can adapt to uneven surfaces, minor concrete imperfections, and structural movements, forming a reliable watertight seal.

The waterstop is compatible with concrete, grout, PU coatings, bitumen membranes, and other waterproofing materials, allowing integration into broader waterproofing systems.

Its chemical resistance ensures it can withstand contact with chlorides, sulfates, and other aggressive agents found in groundwater, sewage, or industrial environments. Swell Bar maintains its performance in extreme temperature variations, ensuring that the structure remains protected year-round.

Professional contractors and engineers prefer Swell Bar for critical structures such as dams, tunnels, water tanks, basements, bridges, retaining walls, and industrial facilities.

because it ensures permanent waterproofing and structural integrity. Its hydrophilic expansion provides superior sealing capacity compared to traditional rubber or PVC waterstops, offering reliable protection against hydrostatic pressure, leakage, and moisture intrusion.

The installation process of Swell Bar is straightforward, but attention to joint preparation is essential for optimal performance. Joints must be clean, dry, and free from debris or loose material.

The waterstop is positioned in the joint, fixed mechanically or with adhesive, and concrete is poured carefully to embed it properly. Once in place, the Swell Bar expands upon contact with water, creating a monolithic barrier that prevents water from entering the structure.

Swell Bar also reduces maintenance costs by eliminating recurring water leakage issues that are common with poorly sealed joints. Its long-term reliability ensures that structures remain leak-free, safe, and durable for decades.

By preventing seepage and water damage, it contributes to the structural longevity of concrete elements, reduces repair costs, and enhances the value of the building or infrastructure project.

The waterstop is highly effective in basements, where groundwater pressure and hydrostatic forces can compromise structural integrity.

By sealing construction and expansion joints, Swell Bar keeps basements dry, protects reinforcement from corrosion, and prevents dampness from affecting interior finishes. Its hydrophilic properties allow it to respond to water exposure dynamically, ensuring a watertight seal even under varying moisture conditions.

Swell Bar is widely used in civil engineering projects, including dams, canals, tunnels, retaining walls, water treatment plants, and sewage systems, where water control and joint sealing are critical. Its superior expansion capacity, flexibility, and chemical resistance.

make it a preferred choice for high-performance waterproofing solutions. The product is essential for modern construction practices in Pakistan, where heavy rainfall, groundwater, and high water tables can pose significant challenges.

The durability of Swell Bar ensures that even after years of exposure to moisture, temperature fluctuations, and hydrostatic pressure,

it maintains its swelling capacity and sealing performance. This makes it a cost-effective solution for long-term waterproofing, minimizing the need for repeated maintenance, structural repairs, and costly interventions. Contractors and engineers rely on its predictable and consistent performance to ensure structural safety and water-tightness across all applications.

Its hydrophilic expansion mechanism ensures that even minor cracks or gaps in joints are sealed automatically when water is present, preventing seepage and infiltration.

This dynamic response makes Swell Bar superior to conventional waterstops, as it adapts to changing moisture conditions and structural movements without losing effectiveness. Its flexibility and resilience make it suitable for high-stress areas such as tunnels, dams, canals, and heavily reinforced concrete structures.

Swell Bar contributes to energy efficiency and sustainability by preventing water ingress that can compromise insulation, flooring, and interior finishes.

By maintaining dry conditions within basements, tunnels, and water-retaining structures, it supports thermal insulation, reduces mold growth, and improves indoor environmental quality. Its long-term performance ensures that buildings and infrastructure projects remain safe, efficient, and operational without frequent repairs or maintenance.

The waterstop is available in standard and custom lengths, widths, and profiles to meet project-specific requirements. It can be combined with additional waterproofing systems, such as PU coatings, bitumen membranes, crystalline additives, or polymer-modified cementitious layers.

for enhanced protection in critical areas. Its versatility allows engineers to design comprehensive waterproofing solutions that address site-specific challenges, ensuring total protection from water infiltration.

Swell Bar is manufactured to meet international quality standards, ensuring consistent performance, durability, and reliability. Its hydrophilic properties, flexibility, chemical resistance, and long-term stability make it an essential product for dams, tunnels, basements.

water tanks, and other high-risk water-retaining structures. Its installation ensures that water infiltration is effectively prevented, protecting the structure from deterioration, reinforcement corrosion, and surface damage.

Professional contractors and construction companies prefer Swell Bar for its ease of handling, adaptability, and long-lasting waterproofing performance. It reduces labor time.

simplifies installation, and integrates seamlessly with concrete and other waterproofing systems. Its hydrophilic expansion ensures that once installed, the joint is automatically sealed when exposed to water, providing continuous protection without manual intervention or maintenance.

In critical infrastructure projects, Swell Bar provides a reliable solution for waterproofing construction joints, expansion joints, and cold joints. Its use in dams, tunnels, retaining walls, basements, and water tanks ensures structural safety, operational efficiency.

and long-term durability. Its superior performance in preventing seepage, leaks, and water damage makes it the preferred choice for high-value construction projects that require guaranteed waterproofing protection.

The product’s resilience to hydrostatic pressure, temperature variations, and chemical exposure ensures that it remains effective in a wide range of environmental conditions.

Its hydrophilic mechanism allows it to respond dynamically to moisture, expanding to fill voids and cracks in joints, preventing water ingress, and maintaining the integrity of concrete structures. This makes it particularly suitable for basements, tunnels, water-retaining structures, and underground facilities.

Swell Bar enhances the lifespan of concrete structures by preventing water-related damage such as corrosion of reinforcement, cracking, spalling, and interior dampness. Its installation in construction, expansion, and contraction joints creates a permanent barrier.

that protects structures for decades, reducing the need for costly repairs, maintenance, and structural intervention. Its long-term performance makes it an essential component of modern waterproofing systems in Pakistan.

The hydrophilic waterstop is widely used in tunnels, dams, canals, basements, bridges, retaining walls, and water tanks due to its superior sealing capacity, flexibility, and chemical resistance. It ensures continuous waterproofing protection.

prevents structural deterioration, and maintains operational efficiency in high-risk water-retaining applications. Its high reliability and performance make it the preferred choice for contractors, engineers, and construction consultants.

Swell Bar is an advanced hydrophilic waterstop designed to provide leak-free protection for concrete structures, ensuring complete waterproofing and long-term structural stability.

Its high-performance formulation expands on contact with water, filling construction joints, expansion joints, contraction joints, and cold joints, creating a continuous, reliable barrier against water infiltration.

This innovative solution is widely used in dams, tunnels, basements, water tanks, retaining walls, canals, and other critical concrete structures where waterproofing is essential for durability and safety.

The advanced hydrophilic properties of Swell Bar allow it to absorb moisture and swell up to several times.

its original volume, forming a tight seal in concrete joints that prevents seepage, leakage, and dampness. Its flexibility accommodates minor movements, cracks, and structural shifts while maintaining a watertight barrier.

making it ideal for high-value construction projects where permanent protection is required. Contractors, engineers, and builders rely on Swell Bar for its exceptional performance, ease of installation, and long-term reliability.

Swell Bar is made from high-quality elastomeric hydrophilic material, ensuring chemical resistance, durability, and long-lasting performance even under extreme environmental conditions.

It can resist groundwater pressure, hydrostatic stress, and aggressive chemicals, making it suitable for industrial, commercial, and residential applications. Its unique design and high swelling capacity guarantee effective sealing of joints in concrete, preventing water-related damage such as reinforcement corrosion, concrete spalling, mold growth, and structural weakening.

The waterstop is easy to install, making it convenient for contractors and construction teams. It can be embedded in fresh concrete during pouring or retrofitted in existing joints with proper surface preparation, offering versatile solutions for both new constructions and renovation projects.

Its adhesive backing or mechanical fixing ensures firm placement, and once concrete is poured, Swell Bar integrates seamlessly into the structure, creating a permanent watertight joint.

Swell Bar provides exceptional performance in dams and water-retaining structures where water pressure is high.

Its ability to expand in contact with water prevents seepage through construction and expansion joints, maintaining water levels, structural stability, and operational efficiency. Similarly, in tunnels, basements, canals, and retaining walls, it ensures dry, safe, and durable structures, protecting interiors, reinforcement, and finishes from water damage.

The hydrophilic waterstop also improves the longevity of concrete structures by reducing water penetration, which can cause corrosion, cracking, and weakening of the material.

By preventing water ingress, Swell Bar protects plaster, tiles, flooring, and other finishes, ensuring interiors remain dry, safe, and hygienic. It is ideal for high-rise buildings, industrial facilities, residential complexes, hospitals, schools, and commercial projects that require permanent waterproofing solutions.

Swell Bar is available in various profiles, widths, and thicknesses to suit different joint sizes and types. Central bulb, dumbbell.

trapezoidal, and other specialized profiles allow precise installation in expansion joints, construction joints, and contraction joints, maximizing the sealing efficiency and performance. Its flexibility ensures that it can adapt to uneven surfaces, minor concrete imperfections, and structural movements, forming a reliable watertight seal.

The waterstop is compatible with concrete, grout, PU coatings, bitumen membranes, and other waterproofing materials, allowing integration into broader waterproofing systems.

Its chemical resistance ensures it can withstand contact with chlorides, sulfates, and other aggressive agents found in groundwater, sewage, or industrial environments. Swell Bar maintains its performance in extreme temperature variations, ensuring that the structure remains protected year-round.

Professional contractors and engineers prefer Swell Bar for critical structures such as dams, tunnels, water tanks, basements, bridges, retaining walls, and industrial facilities.

because it ensures permanent waterproofing and structural integrity. Its hydrophilic expansion provides superior sealing capacity compared to traditional rubber or PVC waterstops, offering reliable protection against hydrostatic pressure, leakage, and moisture intrusion.

The installation process of Swell Bar is straightforward, but attention to joint preparation is essential for optimal performance. Joints must be clean, dry, and free from debris or loose material.

The waterstop is positioned in the joint, fixed mechanically or with adhesive, and concrete is poured carefully to embed it properly. Once in place, the Swell Bar expands upon contact with water, creating a monolithic barrier that prevents water from entering the structure.

Swell Bar also reduces maintenance costs by eliminating recurring water leakage issues that are common with poorly sealed joints. Its long-term reliability ensures that structures remain leak-free, safe, and durable for decades.

By preventing seepage and water damage, it contributes to the structural longevity of concrete elements, reduces repair costs, and enhances the value of the building or infrastructure project.

The waterstop is highly effective in basements, where groundwater pressure and hydrostatic forces can compromise structural integrity.

By sealing construction and expansion joints, Swell Bar keeps basements dry, protects reinforcement from corrosion, and prevents dampness from affecting interior finishes. Its hydrophilic properties allow it to respond to water exposure dynamically, ensuring a watertight seal even under varying moisture conditions.

Swell Bar is widely used in civil engineering projects, including dams, canals, tunnels, retaining walls, water treatment plants, and sewage systems, where water control and joint sealing are critical. Its superior expansion capacity, flexibility, and chemical resistance.

make it a preferred choice for high-performance waterproofing solutions. The product is essential for modern construction practices in Pakistan, where heavy rainfall, groundwater, and high water tables can pose significant challenges.

The durability of Swell Bar ensures that even after years of exposure to moisture, temperature fluctuations, and hydrostatic pressure,

it maintains its swelling capacity and sealing performance. This makes it a cost-effective solution for long-term waterproofing, minimizing the need for repeated maintenance, structural repairs, and costly interventions. Contractors and engineers rely on its predictable and consistent performance to ensure structural safety and water-tightness across all applications.

Its hydrophilic expansion mechanism ensures that even minor cracks or gaps in joints are sealed automatically when water is present, preventing seepage and infiltration.

This dynamic response makes Swell Bar superior to conventional waterstops, as it adapts to changing moisture conditions and structural movements without losing effectiveness. Its flexibility and resilience make it suitable for high-stress areas such as tunnels, dams, canals, and heavily reinforced concrete structures.

Swell Bar contributes to energy efficiency and sustainability by preventing water ingress that can compromise insulation, flooring, and interior finishes.

By maintaining dry conditions within basements, tunnels, and water-retaining structures, it supports thermal insulation, reduces mold growth, and improves indoor environmental quality. Its long-term performance ensures that buildings and infrastructure projects remain safe, efficient, and operational without frequent repairs or maintenance.

The waterstop is available in standard and custom lengths, widths, and profiles to meet project-specific requirements. It can be combined with additional waterproofing systems, such as PU coatings, bitumen membranes, crystalline additives, or polymer-modified cementitious layers.

for enhanced protection in critical areas. Its versatility allows engineers to design comprehensive waterproofing solutions that address site-specific challenges, ensuring total protection from water infiltration.

Swell Bar is manufactured to meet international quality standards, ensuring consistent performance, durability, and reliability. Its hydrophilic properties, flexibility, chemical resistance, and long-term stability make it an essential product for dams, tunnels, basements.

water tanks, and other high-risk water-retaining structures. Its installation ensures that water infiltration is effectively prevented, protecting the structure from deterioration, reinforcement corrosion, and surface damage.

Professional contractors and construction companies prefer Swell Bar for its ease of handling, adaptability, and long-lasting waterproofing performance. It reduces labor time.

simplifies installation, and integrates seamlessly with concrete and other waterproofing systems. Its hydrophilic expansion ensures that once installed, the joint is automatically sealed when exposed to water, providing continuous protection without manual intervention or maintenance.

In critical infrastructure projects, Swell Bar provides a reliable solution for waterproofing construction joints, expansion joints, and cold joints. Its use in dams, tunnels, retaining walls, basements, and water tanks ensures structural safety, operational efficiency.

and long-term durability. Its superior performance in preventing seepage, leaks, and water damage makes it the preferred choice for high-value construction projects that require guaranteed waterproofing protection.

The product’s resilience to hydrostatic pressure, temperature variations, and chemical exposure ensures that it remains effective in a wide range of environmental conditions.

Its hydrophilic mechanism allows it to respond dynamically to moisture, expanding to fill voids and cracks in joints, preventing water ingress, and maintaining the integrity of concrete structures. This makes it particularly suitable for basements, tunnels, water-retaining structures, and underground facilities.

Swell Bar enhances the lifespan of concrete structures by preventing water-related damage such as corrosion of reinforcement, cracking, spalling, and interior dampness. Its installation in construction, expansion, and contraction joints creates a permanent barrier.

that protects structures for decades, reducing the need for costly repairs, maintenance, and structural intervention. Its long-term performance makes it an essential component of modern waterproofing systems in Pakistan.

The hydrophilic waterstop is widely used in tunnels, dams, canals, basements, bridges, retaining walls, and water tanks due to its superior sealing capacity, flexibility, and chemical resistance. It ensures continuous waterproofing protection.

prevents structural deterioration, and maintains operational efficiency in high-risk water-retaining applications. Its high reliability and performance make it the preferred choice for contractors, engineers, and construction consultants.

✅ H2, H3, H4 Headings for SEO

H2 Headings (Broad & Keyword-Rich)

H2: Swell Bar | Premium Hydrophilic Waterstop for Leak-Free Concrete Structures

H2: Protect Your Dams, Tunnels, Basements, and Water Tanks from Seepage

H2: Long-Term Waterproofing Solution for Residential, Commercial, and Industrial Projects

H2: Advanced Expansion Joint Sealing Technology for Structural Durability

H2: Benefits of Using Swell Bar for Concrete Joint Waterproofing

H2: Why Engineers and Contractors Trust Swell Bar for High-Value Projects

H2: Complete Protection Against Water Ingress, Leakage, and Moisture Damage

H3 Headings (Detailed, Product-Focused)

H3: Effective Joint Sealing for Construction, Expansion, and Contraction Joints

H3: Hydrophilic Expansion Mechanism for Automatic Leak Prevention

H3: Long-Term Performance in Dams, Tunnels, Water Tanks, and Basements

H3: Chemical and Environmental Resistance for Industrial Applications

H3: Easy Installation with Reliable Adhesion in Fresh and Existing Concrete

H3: Preventing Structural Damage, Corrosion, and Mold Growth

H3: High-Performance Waterproofing for Residential and Commercial Structures

H3: Seamless Integration with Other Waterproofing Systems

H4 Headings (Specific, Deep-Level Keywords)

H4: Heavy-Duty Waterstop for High Hydrostatic Pressure Applications

H4: Flexible Profile for Uneven Surfaces and Minor Structural Movements

H4: Central Bulb, Dumbbell, and Trapezoidal Profiles for Maximum Efficiency

H4: Long-Term Sealing for Basements, Tunnels, Retaining Walls, and Canals

H4: Protecting Concrete from Cracks, Seepage, and Reinforcement Corrosion

H4: Hydrophilic Material Resistant to Chemical Attack and UV Exposure

H4: Reduces Maintenance Costs and Extends Structural Lifespan

H4: Professional-Grade Waterproofing for Mega Projects in Pakistan

H4: Dynamic Waterstop that Swells on Contact with Water for Complete Barrier