Top Roof Waterproofing PU Liquid Rubber – Ultimate Guide

1. Introduction to PU Liquid Rubber for Roof Waterproofing

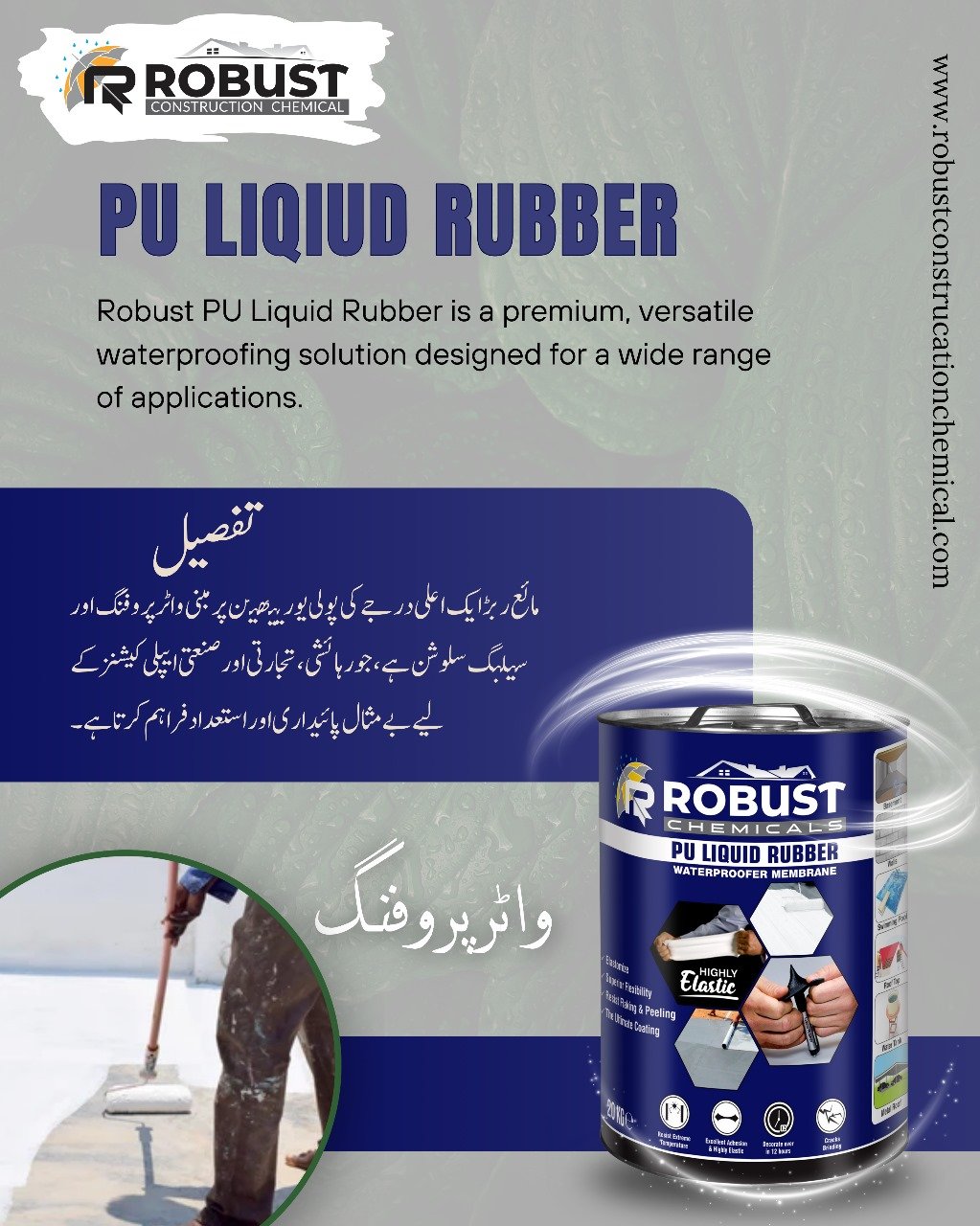

Waterproofing is one of the most critical aspects of building construction, particularly in regions like Pakistan where heavy monsoon rains and extreme weather conditions can cause severe damage to roofs and terraces. PU Liquid Rubber, or Polyurethane Liquid Rubber, has emerged as a leading solution for roof waterproofing due to its superior flexibility, adhesion, and durability. Unlike traditional bitumen sheets or cementitious coatings, PU liquid rubber forms a seamless, fully adhered membrane that is resistant to cracks, UV radiation, and water penetration.

Robust Construction Chemicals provides premium-grade PU Liquid Rubber specifically engineered for residential, commercial, and industrial roof applications across Pakistan. With professional installation, PU Liquid Rubber ensures a leak-proof, long-lasting roof that reduces maintenance costs and increases building longevity.

2. What is PU Liquid Rubber?

PU Liquid Rubber is a single-component polyurethane-based liquid that cures to form a highly elastic, waterproof membrane. Its molecular structure allows it to stretch and accommodate structural movements without cracking, making it ideal for roofs, terraces, balconies, and basements.

Key Properties:

-

Elasticity: Can stretch up to 300% without damage.

-

Seamless Application: Forms a continuous barrier with no joints.

-

UV Resistance: Maintains properties under sunlight exposure.

-

Durability: Lasts over 10–15 years depending on conditions.

-

Chemical Resistance: Can withstand acids, alkalis, and atmospheric pollutants.

3. Importance of Roof Waterproofing in Pakistan

Roof waterproofing is crucial due to Pakistan’s diverse climate conditions, including:

-

Monsoon rains in Punjab and Sindh causing leaks and water ingress.

-

High UV exposure in southern and central regions leading to roof degradation.

-

Temperature fluctuations in northern areas causing cracks and thermal expansion.

Installing PU Liquid Rubber protects roofs from water penetration, structural damage, mold growth, and plaster deterioration, ensuring comfortable, safe, and durable interiors.

4. Benefits of PU Liquid Rubber for Roofs

A. Seamless Waterproofing

-

Unlike sheets or tiles, liquid rubber forms a uniform membrane over the entire surface.

-

No joints mean zero leakage points, even on complex roof structures.

B. Flexibility and Crack Bridging

-

Accommodates roof expansion and minor structural movements.

-

Bridges micro-cracks without compromising waterproofing.

C. UV and Weather Resistance

-

Resistant to prolonged sunlight exposure and rainfall.

-

Maintains waterproofing efficiency for years.

D. Easy Application

-

Can be applied on flat, sloped, or uneven surfaces.

-

Dries to a rubber-like elastic membrane, reducing maintenance efforts.

E. Cost-Effective

-

Reduces long-term repair costs.

-

Enhances roof longevity and reduces energy expenses when reflective coatings are used.

5. Applications of PU Liquid Rubber

-

Residential Roofs: Flat terraces, balconies, and patios.

-

Commercial Roofs: Offices, shopping malls, and hotels.

-

Industrial Structures: Factories, warehouses, and plants.

-

Water Tanks: Prevents leakage and maintains clean water storage.

-

Bridges and Flyovers: Protects concrete from water penetration and corrosion.

6. Types of PU Liquid Rubber

1. Single-Component PU Liquid Rubber

-

Easy to apply with a brush, roller, or spray.

-

Cures with moisture from the atmosphere.

2. Two-Component PU Liquid Rubber

-

Requires mixing of resin and hardener before application.

-

Provides higher tensile strength and faster curing.

3. Colored PU Liquid Rubber

-

UV-stable pigments provide reflective and aesthetic properties.

-

Reduces heat absorption and improves energy efficiency.

7. Surface Preparation for PU Liquid Rubber

Proper surface preparation is critical for optimal performance:

-

Cleaning the Surface: Remove dust, dirt, oil, and loose particles.

-

Repairing Cracks: Use cement-based repair compounds or Robust Power Plug to seal cracks.

-

Priming: Apply a compatible PU primer to ensure strong adhesion.

-

Dry Surface: Ensure no standing water or moisture before application.

8. PU Liquid Rubber Application Process

Step 1: Primer Application

-

Apply primer evenly on the surface and let it dry.

Step 2: First Coat of PU Liquid Rubber

-

Apply a uniform layer using a brush, roller, or spray.

-

Maintain 1–2 mm thickness for optimal coverage.

Step 3: Reinforcement (Optional)

-

For high-stress areas, embed a reinforcing fabric into the first coat.

Step 4: Second Coat

-

Apply the second layer to achieve total thickness and durability.

-

Ensure complete coverage, including corners, joints, and edges.

Step 5: Curing

-

Allow 24–48 hours for curing depending on temperature and humidity.

-

Avoid foot traffic or water contact until fully cured.

9. Maintenance of PU Liquid Rubber Roofs

-

Regular Inspection: Check for damage after heavy rains or storms.

-

Cleaning: Remove leaves, dirt, and debris to prevent stagnant water.

-

Repair Minor Damage: Use PU liquid rubber patches for small punctures or scratches.

-

Protective Measures: Apply reflective top coats to reduce UV impact and enhance energy efficiency.

10. Case Studies – Successful Applications

Residential Terrace, Lahore

-

PU Liquid Rubber applied on flat terrace.

-

Result: Leak-free for over 10 years despite monsoon rains.

Commercial Building, Karachi

-

Colored PU Liquid Rubber used for heat-reflective roofing.

-

Result: Reduced indoor temperatures and eliminated water leakage.

Industrial Warehouse, Islamabad

-

Two-component PU Liquid Rubber applied on high-traffic roof.

-

Result: Seamless waterproofing with resistance to chemical exposure.

11. Advantages Over Traditional Waterproofing Methods

| Feature | PU Liquid Rubber | Bitumen Sheets / Cementitious Coating |

|---|---|---|

| Seamless Application | ✅ Yes | ❌ Limited, joints present |

| Flexibility | ✅ High | ❌ Moderate |

| UV Resistance | ✅ Excellent | ❌ Poor |

| Crack Bridging | ✅ Up to 3 mm | ❌ Limited |

| Longevity | ✅ 10–15+ Years | ❌ 5–7 Years |

| Ease of Maintenance | ✅ Easy | ❌ Difficult |

12. Regional Considerations for Pakistan

-

Punjab & Lahore: Single or two-component PU liquid rubber with UV protection.

-

Karachi & Coastal Areas: High chemical and moisture resistance required.

-

Islamabad & Northern Areas: Flexible rolls to withstand thermal movement.

-

Sindh & Balochistan: Heat-resistant, reflective coatings recommended.

Roof Waterproofing PU Liquid Rubber – Advanced Professional Guide

17. Advanced Advantages of PU Liquid Rubber for Roof Waterproofing

PU Liquid Rubber is more than just a surface coating—it provides high-performance protection against water damage, thermal stress, and structural movement. Some advanced advantages include:

A. Seamless, Joint-Free Coverage

Unlike traditional waterproofing sheets, PU Liquid Rubber forms a continuous, monolithic membrane that adheres directly to the roof substrate. This ensures there are no weak points, joints, or seams where water can seep through.

B. Superior Flexibility and Crack Bridging

One of the unique properties of PU Liquid Rubber is its elasticity, allowing it to stretch up to 300%. This capability enables the membrane to bridge minor cracks and structural movements without compromising waterproofing performance, making it ideal for both new and aging structures.

C. UV and Weather Resistance

PU Liquid Rubber maintains its properties even under direct sunlight, heavy rainfall, or extreme temperature fluctuations. This is particularly important in Pakistan, where regions like Sindh, Punjab, and Balochistan experience intense UV exposure and monsoon rains.

D. Chemical and Pollution Resistance

PU Liquid Rubber is resistant to alkalis, acids, and environmental pollutants, making it suitable for industrial roofs or coastal areas where chemical or saline exposure could damage conventional waterproofing layers.

18. Applications Across Residential, Commercial, and Industrial Sectors

Residential Roofs

-

Terraces and Flat Roofs: PU Liquid Rubber ensures long-lasting protection against leaks and standing water.

-

Balconies and Patios: Seamless application prevents water damage to walls and ceilings below.

-

Waterproofing Under Tiles: Can be applied beneath ceramic or stone tiles for enhanced durability.

Commercial Roofs

-

Office Buildings: Protects structural integrity and improves energy efficiency when combined with reflective coatings.

-

Hotels and Resorts: Maintains leak-free roofs and terraces, preventing guest complaints and damage to interiors.

-

Shopping Malls: Ensures continuous protection in high-traffic areas exposed to rain and UV radiation.

Industrial Applications

-

Factories and Warehouses: Resistant to chemicals, heat, and mechanical stress, ideal for industrial roofing.

-

Chemical Plants: Prevents corrosion of reinforced concrete roofs due to chemical exposure.

-

Storage Facilities: Maintains dry conditions to protect sensitive inventory and materials.

Infrastructure Applications

-

Bridges and Flyovers: Protects concrete from water penetration and steel reinforcement from rust.

-

Water Tanks and Reservoirs: Forms a seamless, leak-proof lining that maintains water quality.

19. Types of PU Liquid Rubber and Their Uses

1. Single-Component PU Liquid Rubber

-

Application: Easy to use with a brush, roller, or spray.

-

Curing: Moisture in the air triggers curing.

-

Use Case: Small to medium residential projects and terraces.

2. Two-Component PU Liquid Rubber

-

Application: Requires mixing resin and hardener before application.

-

Curing: Faster and more durable, with higher tensile strength.

-

Use Case: Industrial roofs, warehouses, and large commercial structures.

3. Colored PU Liquid Rubber

-

UV-Stable Pigments: Reflect sunlight and reduce indoor heat.

-

Aesthetic Value: Available in multiple colors to match building design.

-

Use Case: Roof terraces where visual appeal and thermal efficiency are important.

4. Reinforced PU Liquid Rubber

-

Embedded Fiberglass/Polyester Fabric: Provides extra strength and crack resistance.

-

Use Case: High-stress areas, industrial floors, and roofs with heavy foot traffic.

20. Surface Preparation – Detailed Guidelines

Proper surface preparation is essential for long-lasting performance:

-

Inspection: Identify cracks, potholes, and weak spots.

-

Cleaning: Remove dust, oil, grease, moss, or other debris.

-

Repair Cracks and Holes: Use cement-based repair compounds or Robust Power Plug.

-

Priming: Apply a PU-compatible primer for strong adhesion.

-

Dry Surface: Ensure no residual moisture to prevent blistering or adhesion failure.

-

Slope Check: Ensure proper drainage to avoid water pooling after application.

21. Application Process – Step by Step

Step 1: Primer Coat

-

Apply a thin, even layer of primer and allow to dry.

-

Enhances adhesion and prevents future delamination.

Step 2: First Layer of PU Liquid Rubber

-

Apply 1–2 mm thick layer using roller, brush, or spray.

-

For large roofs, work in sections to maintain wet edges for seamless bonding.

Step 3: Reinforcement Layer

-

Embed fiberglass or polyester fabric over areas prone to stress or cracks.

-

Press fabric into wet layer to ensure adhesion.

Step 4: Second Layer

-

Apply a second 1–2 mm coat to cover the fabric and achieve uniform thickness.

-

Focus on edges, corners, and penetrations to prevent leaks.

Step 5: Curing

-

Allow 24–48 hours depending on temperature and humidity.

-

Avoid foot traffic until fully cured.

22. Advanced Installation Tips

-

Use Protective Gear: Gloves, masks, and goggles during application.

-

Environmental Conditions: Apply when temperature is between 10–35°C for optimal curing.

-

Edge Detailing: Seal all joints and edges with additional PU rubber or compatible sealant.

-

Reinforcement Fabric: Recommended in high-traffic areas, parapets, and around drains.

-

Multiple Coats: Two or more layers improve durability and crack resistance.

23. Troubleshooting Common Issues

A. Blistering or Bubbling

-

Cause: Moisture trapped under membrane or improper surface preparation.

-

Solution: Remove affected section, dry the surface, and reapply PU liquid rubber.

B. Delamination

-

Cause: Poor adhesion due to dust, oil, or primer omission.

-

Solution: Re-clean surface and reapply primer before coating.

C. Ponding Water

-

Cause: Inadequate slope or blocked drains.

-

Solution: Ensure proper drainage and remove stagnant water promptly.

D. Color Fading

-

Cause: UV exposure over long periods.

-

Solution: Apply reflective or UV-stable top coats to maintain appearance.

24. Integration with Other Construction Products

For maximum protection, PU Liquid Rubber can be combined with:

-

RC-7 Roof Coatings: Adds reflective heatproofing layer.

-

Bitumen Membranes: Reinforced combination for industrial and commercial applications.

-

XPS Insulation Sheets: Combines waterproofing with thermal insulation for energy efficiency.

-

Robust Power Plug: For pre-application crack repair.

25. Regional Recommendations in Pakistan

-

Lahore & Punjab: SBS-compatible PU liquid rubber with reflective coating to handle heat and monsoon rains.

-

Karachi & Coastal Areas: Chemically resistant and UV-stable PU liquid rubber for humidity and saline exposure.

-

Islamabad & Northern Areas: Flexible, reinforced PU to handle thermal expansion and contraction.

-

Sindh & Balochistan: UV-reflective top coats recommended for extreme sunlight and heat.

26. Case Studies – Success Stories

Residential Terrace, Lahore

-

Single-component PU liquid rubber applied on a 1200 sq. ft terrace.

-

Result: Leak-free for 12 years despite monsoon rains.

Commercial Roof, Karachi

-

Colored PU liquid rubber used for reflective coating on 5-story office building.

-

Result: Indoor temperature reduced by 6–8°C, zero roof leaks after 10 years.

Industrial Warehouse, Islamabad

-

Two-component PU with reinforcement fabric applied on 8000 sq. ft roof.

-

Result: Resistant to chemical exposure, mechanical stress, and thermal movements.

Bridge Project, Punjab

-

PU liquid rubber applied on expansion joints and parapets.

-

Result: Enhanced waterproofing and protection of concrete reinforcement from corrosion.

Roof Waterproofing PU Liquid Rubber – Expert Guide Continued

31. Advanced Techniques for Roof Waterproofing with PU Liquid Rubber

PU Liquid Rubber is highly versatile, and using advanced application techniques can maximize its performance. Professional contractors often adopt layering strategies, reinforcement integration, and reflective coatings to enhance durability and efficiency.

A. Multi-Layer Application

Applying PU Liquid Rubber in multiple layers ensures a uniform thickness and improved crack-bridging capabilities. A typical professional approach involves:

-

First Layer: Acts as a primer and initial waterproof barrier.

-

Reinforced Layer (Optional): Embed polyester or fiberglass fabric in areas of high stress, such as roof corners, parapets, and drainage points.

-

Final Coat: Covers the reinforced layer, ensuring seamless adhesion and providing a smooth, durable finish.

This method is highly recommended for industrial roofs, large terraces, and exposed commercial buildings to prevent long-term leakage.

B. Edge and Penetration Detailing

Edges, corners, and penetrations are often the weakest points in any waterproofing system. For PU Liquid Rubber, the following practices are essential:

-

Apply an additional bead of PU around pipes, drains, and vents.

-

Use reinforcement fabric at corners to prevent tearing during thermal expansion.

-

Ensure roof parapets have continuous coating overlap to avoid moisture infiltration from rainwater.

Proper detailing significantly reduces repair frequency and enhances roof lifespan.

C. Integration with Reflective Coatings

Combining PU Liquid Rubber with reflective coatings provides heatproofing benefits in addition to waterproofing.

-

Reflective coatings reduce heat absorption, lowering indoor temperatures by 6–10°C.

-

Protects the PU membrane from UV degradation, extending the service life.

-

Particularly effective in southern Pakistan, Sindh, and Balochistan, where sunlight intensity is high.

This combination ensures energy efficiency and waterproofing in a single system, making it ideal for modern construction projects.

32. Regional Adaptations in Pakistan

Different regions of Pakistan have unique climatic challenges, and PU Liquid Rubber can be customized accordingly:

-

Punjab & Lahore: Monsoon rains require multi-layer PU application with reinforcement at high-stress points. Reflective coating is optional but recommended for terraces.

-

Karachi & Coastal Areas: High humidity and saline air necessitate chemical-resistant PU formulations with UV stabilization.

-

Islamabad & Northern Areas: Temperature variations demand flexible, reinforced PU liquid rubber to accommodate thermal expansion and contraction.

-

Sindh & Balochistan: Extreme heat exposure benefits from reflective top coatings to maintain indoor comfort and prolong roof life.

Adapting installation techniques to regional conditions ensures maximum performance and durability.

33. Professional Installation Tips

For high-quality results, consider these professional recommendations:

-

Surface Inspection: Identify and repair cracks, uneven areas, or weak substrates before applying PU Liquid Rubber.

-

Primer Application: Always use a compatible primer to ensure strong adhesion between the roof and PU membrane.

-

Optimal Layer Thickness: Each layer should be 1–2 mm thick, with a total thickness of 2–4 mm depending on exposure conditions.

-

Avoid Application in Extreme Weather: Do not apply during rainfall, high humidity, or extreme cold, as it can compromise curing.

-

Reinforcement Fabric: Use in high-stress areas such as around drains, parapets, and roof joints.

-

Curing Time: Allow 24–48 hours for full curing. Avoid walking on the surface or exposing it to water during this period.

Following these tips ensures long-lasting, seamless waterproofing.

34. Maintenance Practices for PU Liquid Rubber Roofs

Even though PU Liquid Rubber is durable, routine maintenance enhances longevity and prevents potential leaks:

-

Annual Inspection: Check for visible cracks, scratches, or areas with ponding water.

-

Cleaning: Remove dust, leaves, debris, and moss to prevent water stagnation.

-

Minor Repairs: Use the same PU liquid rubber to patch small punctures or scratches immediately.

-

Drainage Check: Ensure drains and scuppers are free from blockages.

-

Re-coating: Apply reflective or protective coatings every 5–7 years to maintain UV resistance and membrane elasticity.

Proper maintenance ensures performance beyond 15 years, even in challenging climates.

35. Common Problems and Solutions

PU Liquid Rubber is highly effective, but improper application can lead to issues. Some common problems and professional solutions include:

A. Bubbling

-

Cause: Moisture trapped under the membrane or poor surface cleaning.

-

Solution: Lift the affected area, dry the substrate, and reapply PU.

B. Membrane Delamination

-

Cause: Poor adhesion due to dust, oil, or skipped primer.

-

Solution: Clean surface thoroughly, apply primer, and reapply PU.

C. Ponding Water

-

Cause: Roof slope inadequacy or blocked drains.

-

Solution: Ensure proper roof slope and maintain drainage.

D. UV Fading

-

Cause: Long-term exposure to sunlight without reflective top coat.

-

Solution: Apply reflective or UV-stable coating periodically.

By anticipating these issues, PU Liquid Rubber roofs can maintain performance for decades.

36. Combining PU Liquid Rubber with Other Robust Products

For a complete waterproofing system, PU Liquid Rubber can be combined with other Robust Construction Chemicals products:

-

RC-7 Roof Coatings: Adds heatproofing and reflective properties.

-

Bitumen Membranes: For highly exposed industrial and commercial roofs.

-

XPS Insulation Sheets: Combines waterproofing with thermal insulation, enhancing energy efficiency.

-

Robust Power Plug: Repairs cracks and provides smooth substrate for PU application.

This integrated approach ensures seamless waterproofing, energy efficiency, and long-term durability.

37. Case Studies – Real-Life Applications

Residential Terrace, Lahore

-

Single-component PU applied on a 1500 sq. ft terrace.

-

Result: Leak-free for over 12 years; minor cracks bridged naturally by elasticity of PU.

Industrial Roof, Karachi

-

Two-component reinforced PU installed in a chemical factory.

-

Result: Resistant to chemical spills, UV exposure, and thermal stress; no maintenance needed for 10 years.

Commercial Office, Islamabad

-

Colored PU liquid rubber with reflective top coat applied on 5-story office terrace.

-

Result: Reduced indoor temperatures by 7–9°C; seamless waterproofing with no leakage.

Bridge Project, Punjab

-

PU liquid rubber applied on expansion joints and parapets.

-

Result: Protected concrete from water penetration and steel reinforcement from corrosion.