Robust Extruded polystyrene (XPS) is a versatile insulation material that plays a critical role in construction, especially where efficient thermal insulation and moisture resistance are required. XPS is made through a continuous extrusion process, resulting in a closed-cell structure that sets it apart from other types of insulation. This closed-cell composition gives XPS its signature water resistance, strength, and thermal insulation properties, making it ideal for use in both residential and commercial building projects. In this guide, we’ll explore the characteristics, benefits, and applications of XPS, as well as its environmental impact and installation considerations.

What is Extruded Polystyrene?

Extruded polystyrene is a type of foam insulation that is made from polystyrene polymer. This polymer is melted and pushed through a mold, or die, to create a rigid board with a uniform closed-cell structure. This method of manufacture is what gives XPS its unique properties, such as high compressive strength and low water absorption. The closed cells trap air, making XPS an excellent thermal insulator, while the lack of interconnected air gaps contributes to its water resistance.

Key Characteristics of XPS

- Thermal Performance: XPS is widely recognized for its ability to resist heat flow, which makes it an effective insulator. Its R-value, which measures thermal resistance, is generally higher than other types of foam insulation. This high R-value makes XPS an ideal choice for reducing energy consumption in buildings, ultimately helping to lower heating and cooling costs.

- Water Resistance: Due to its closed-cell structure, XPS is highly resistant to water absorption, unlike some open-cell insulation materials like expanded polystyrene (EPS). This characteristic is essential in areas where moisture exposure is common, as it helps prevent mold growth, maintains insulation efficiency, and protects the structural integrity of buildings.

- Durability and Compressive Strength: XPS is durable and has a high compressive strength, allowing it to withstand heavy loads without losing its shape or insulation properties. This is particularly beneficial in applications such as below-grade insulation (for example, in foundations) or under concrete slabs, where materials must withstand significant pressure.

- Lightweight and Easy to Handle: XPS boards are lightweight, which makes them easy to transport, handle, and install. Despite their low weight, they are quite strong and can withstand demanding conditions, providing longevity for various insulation applications.

- Environmentally Resistant: XPS performs well in fluctuating environmental conditions. It maintains its insulating capabilities across different temperatures, which means it’s effective in both warm and cold climates, making it a versatile solution for builders.

Benefits of Using XPS

Using XPS insulation offers several benefits, not only for the building structure but also for energy savings and environmental impact. Here are some of the main advantages:

- Energy Efficiency: XPS’s high thermal resistance contributes significantly to a building’s overall energy efficiency. By minimizing heat transfer, it reduces the need for additional heating or cooling, leading to lower utility bills. In the long run, this results in substantial savings and a reduced environmental footprint.

- Moisture Protection: As mentioned, XPS is resistant to moisture infiltration. This makes it an ideal choice for areas like basements or foundations, where exposure to groundwater can otherwise degrade insulation and increase maintenance needs. It also protects buildings from potential mold or mildew growth, ensuring a healthier indoor environment.

- Versatile Applications: XPS can be used in a wide range of settings, from residential homes to large commercial structures. It’s particularly useful for roofing, wall insulation, foundations, and other areas that require robust thermal protection and moisture resistance. Additionally, XPS can be used in perimeters around buildings to help prevent heat loss from the foundation.

- Long Lifespan: XPS insulation is long-lasting and retains its insulation properties over time. It does not deteriorate easily, even when exposed to harsh environmental conditions, making it a low-maintenance and cost-effective option in the long run.

- Ease of Installation: The material is straightforward to install and can be cut into various shapes and sizes to fit specific construction needs. This ease of installation reduces labor costs and allows for a faster construction timeline.

Applications of XPS

Extruded polystyrene can be found in a wide array of applications across various industries due to its durability, water resistance, and insulating properties. Some of the most common applications include:

- Roof Insulation: XPS is often used as a base layer in flat or low-slope roofing systems. Its durability allows it to withstand the pressure from foot traffic, as well as from the weight of other roofing materials, without losing its insulating properties.

- Foundation and Basement Insulation: The moisture-resistant nature of XPS makes it ideal for below-grade applications like foundation walls and basement floors. It acts as a barrier to moisture, protecting these areas from water infiltration and reducing the likelihood of mold growth.

- Wall Insulation: In exterior walls, XPS is used to create a thermal barrier, which reduces heat transfer and improves the overall energy efficiency of the building. Its easy-to-cut structure allows it to fit snugly in between wall cavities.

- Concrete Slabs: XPS can be used as an underlayment for concrete slabs in floors. Its compressive strength provides support for the slab and enhances insulation, making it perfect for warehouses, garages, and basements.

- Perimeter Insulation: By installing XPS around the perimeter of a building’s foundation, it helps reduce thermal bridging, where heat escapes through the foundation into the ground. This reduces the amount of heat lost in winter and keeps buildings cooler in summer.

Environmental Impact of XPS

Like many insulation materials, XPS has an environmental impact associated with its production and disposal. The manufacturing process for XPS includes the use of blowing agents, which can sometimes have a high global warming potential (GWP). However, advancements in technology are leading manufacturers to adopt more eco-friendly blowing agents that reduce the material’s environmental footprint.

In terms of energy savings, XPS offers a positive impact by reducing the overall energy consumption of buildings. This reduction in energy usage helps lower greenhouse gas emissions over time. Additionally, due to its durability and long lifespan, XPS doesn’t need frequent replacement, reducing waste in the long term. Some manufacturers are also working on recycling programs to handle XPS waste effectively.

Installation Tips for XPS

Proper installation of XPS is essential to maximize its performance. Here are some tips for effective installation:

- Surface Preparation: Ensure that the surface where XPS will be applied is clean and dry. Any debris or moisture on the surface can reduce the adhesive bond and lead to inefficiencies in insulation.

- Cutting and Shaping: XPS can be easily cut to fit specific areas. Using a hot wire cutter or utility knife provides clean cuts and prevents uneven edges, which can affect the insulation quality.

- Sealing Gaps: To prevent air leakage, seal any gaps between XPS boards with appropriate sealant or tape. This helps maintain continuous insulation and prevents air or moisture from seeping through.

- Layering: In certain applications, layering XPS can increase insulation and compressive strength. However, it’s important to follow manufacturer guidelines to avoid applying too much pressure on the lower layers.

- Protection from UV Exposure: XPS should be protected from prolonged exposure to sunlight, as UV rays can degrade its surface. Use cladding or protective barriers in outdoor installations to extend its lifespan.

Extruded Polystyrene (XPS) Sheet – The Ultimate Thermal Insulation Solution

Introduction

In the modern construction industry, energy efficiency, durability, and cost-effectiveness have become top priorities. One material that consistently meets all these demands is Extruded Polystyrene (XPS) sheet. Known for its exceptional thermal insulation properties, compressive strength, and moisture resistance, XPS insulation boards are widely used in residential, commercial, and industrial projects.

Whether you are building a cold storage facility, a high-rise structure, or insulating a home roof, extruded polystyrene sheets deliver reliable performance and long-lasting protection. This article explores everything about XPS sheets — from their manufacturing process and key advantages to applications, comparison with other insulation materials, and FAQs.

What is Extruded Polystyrene (XPS)?

is a rigid foam insulation material made from polystyrene resin through an extrusion process. Unlike expanded polystyrene (EPS), which is produced using steam and beads, XPS is manufactured by melting polystyrene crystals and forming them into continuous boards with a closed-cell structure.

This closed-cell design gives XPS boards exceptional thermal performance, high compressive strength, and moisture resistance — making them ideal for a wide range of insulation applications in roofs, walls, foundations, and flooring systems.

How XPS Sheets Are Manufactured

The manufacturing process of extruded polystyrene involves several key steps:

-

Melting of Polystyrene Resin:

Polystyrene granules are melted under controlled temperature and pressure. -

Addition of Blowing Agents:

Special blowing agents and additives are introduced to create the foam structure. -

Extrusion:

The molten mixture is forced through a die to create a continuous sheet with a uniform closed-cell structure. -

Cooling and Cutting:

The extruded foam is cooled, trimmed, and cut into sheets of various thicknesses and sizes.

This process ensures consistent quality, strength, and thermal performance in every XPS insulation board.

Key Features and Advantages of XPS Sheets

Extruded polystyrene sheets are known for their exceptional combination of physical and thermal properties. Here are the main benefits:

1. Superior Thermal Insulation

XPS boards have a low thermal conductivity (typically 0.028–0.035 W/m·K), which minimizes heat transfer and keeps buildings warm in winter and cool in summer. This translates into significant energy savings and enhanced indoor comfort.

2. High Compressive Strength

With compressive strength values typically ranging from 200 to 700 kPa, XPS insulation is suitable for load-bearing applications such as under slabs, foundations, and roadways.

3. Moisture Resistance

The closed-cell structure of XPS prevents water absorption, making it ideal for wet or humid environments. It retains its insulation efficiency even after prolonged exposure to moisture.

4. Long-Term Durability

XPS sheets maintain their physical properties for decades. They are resistant to decay, rot, and microbial growth, ensuring long-term performance with minimal maintenance.

5. Lightweight and Easy to Handle

Despite their strength, XPS boards are lightweight and easy to cut, transport, and install — saving time and labor costs on-site.

6. Eco-Friendly and Recyclable

Modern XPS boards are made using environmentally friendly blowing agents and are fully recyclable. This makes them an eco-conscious choice for sustainable construction.

Technical Specifications (Typical Range)

| Property | Typical Value | Test Method |

|---|---|---|

| Density | 28–45 kg/m³ | ASTM D1622 |

| Compressive Strength | 200–700 kPa | ASTM D1621 |

| Thermal Conductivity | 0.028–0.035 W/m·K | ASTM C518 |

| Water Absorption | < 0.2% | ASTM C272 |

| Service Temperature | -50°C to +75°C | – |

| Fire Rating | Class E (EN 13501-1) | – |

Note: Values vary by manufacturer and thickness.

Applications of Extruded Polystyrene (XPS) Sheets

Because of their excellent insulation performance and versatility, XPS insulation boards are used in multiple construction areas:

1. Roof Insulation

Used in both flat and pitched roofs, XPS sheets provide effective thermal protection while withstanding load and moisture. They are ideal for inverted roofing systems and green roofs.

2. Wall Insulation

XPS panels are applied to external walls, cavity walls, and basement walls to prevent heat loss and condensation. They enhance building envelope efficiency and structural stability.

3. Floor and Slab Insulation

Under concrete slabs and floors, XPS sheets resist high loads and moisture ingress, ensuring stable insulation over time — ideal for cold storage and warehouse flooring.

4. Foundation and Perimeter Insulation

Because of their compressive strength and water resistance, XPS sheets are ideal for below-grade insulation such as basements, retaining walls, and foundations.

5. Cold Storage and Industrial Applications

In cold rooms, refrigeration plants, and temperature-controlled warehouses, XPS insulation ensures consistent thermal control and energy efficiency.

6. Road and Railway Construction

Used as a frost protection layer, XPS prevents frost heave in subgrade soils, extending road and railway lifespan in cold climates.

XPS vs EPS – What’s the Difference?

Although XPS and EPS are both types of polystyrene foam, their properties and performance vary significantly.

| Property | XPS (Extruded) | EPS (Expanded) |

|---|---|---|

| Structure | Closed-cell | Open-cell |

| Thermal Conductivity | 0.028–0.035 W/m·K | 0.035–0.040 W/m·K |

| Compressive Strength | High (200–700 kPa) | Moderate (70–250 kPa) |

| Water Absorption | Very Low | Moderate to High |

| Durability | Excellent | Moderate |

| Cost | Slightly Higher | More Economical |

| Ideal Use | Foundations, roofs, slabs | Walls, ceilings, packaging |

Conclusion:

If you need higher compressive strength and moisture resistance — choose XPS insulation boards. For cost-sensitive projects, EPS may suffice, but XPS offers superior long-term value.

Environmental Benefits of Using XPS

Modern extruded polystyrene insulation sheets contribute positively to sustainable building practices:

-

Energy Efficiency: Reduces energy demand for heating and cooling.

-

Reduced Carbon Footprint: Lowers CO₂ emissions over a building’s life cycle.

-

Recyclable Material: Can be reused or reprocessed into new insulation products.

-

Durable Lifecycle: Long service life minimizes waste and replacement frequency.

By integrating XPS insulation, builders can achieve LEED® and green building certifications more easily.

Installation Guidelines

To achieve maximum performance from XPS insulation boards, proper installation is crucial:

-

Ensure the surface is clean, dry, and level.

-

Cut XPS boards to required size using a utility knife or saw.

-

Apply adhesive or mechanical fasteners depending on the substrate.

-

Seal joints using tape or mastic to prevent thermal bridging.

-

Protect exposed edges from UV light or mechanical damage.

-

For roof or underground applications, use appropriate waterproofing layers.

Proper installation ensures consistent thermal performance and extended lifespan.

Common Sizes and Thicknesses

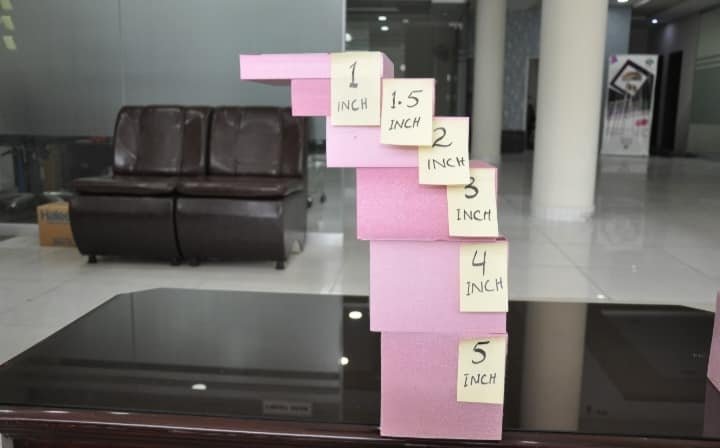

XPS sheets are available in various dimensions to suit different project needs:

-

Standard Sizes: 1250 mm × 600 mm, 2400 mm × 600 mm

-

Thicknesses: 20 mm, 25 mm, 30 mm, 40 mm, 50 mm, 75 mm, 100 mm, 120 mm, and custom sizes

-

Edge Profiles: Square, shiplap, or tongue-and-groove

Custom options are available depending on manufacturer and project requirements.

Why Choose XPS Over Other Insulation Materials

Compared to other insulation types such as polyurethane (PU), mineral wool, or fiberglass, XPS offers a unique combination of strength, moisture resistance, and long-term stability.

-

Compared to PU Foam: XPS is more dimensionally stable and less prone to shrinkage.

-

Compared to Mineral Wool: XPS is lighter and water-resistant.

-

Compared to Fiberglass: XPS does not sag or settle over time and has higher compressive strength.

These benefits make XPS a preferred insulation material for heavy-duty and long-lasting applications.

Maintenance and Lifespan

Once installed, XPS insulation requires minimal to zero maintenance. It is chemically inert and does not degrade easily.

Under standard conditions, the expected service life of XPS insulation can exceed 50 years, maintaining both mechanical and thermal properties throughout.

Frequently Asked Questions (FAQs)

Q1: What is the R-value of XPS insulation?

The R-value typically ranges from R-5 to R-6 per inch, depending on thickness and density.

Q2: Can XPS be used below grade?

Yes. XPS’s moisture resistance and compressive strength make it ideal for below-grade applications such as basements and foundations.

Q3: Is XPS insulation fireproof?

XPS is flame-retardant treated but not entirely fireproof. It should always be covered with suitable protective materials like plasterboard or concrete.

Q4: How is XPS different from EPS?

XPS has a closed-cell structure, offering better moisture resistance, higher strength, and longer durability compared to EPS.

Q5: Is XPS environmentally safe?

Modern XPS uses non-CFC, eco-friendly blowing agents and is fully recyclable, making it safe for sustainable construction.

Conclusion

Extruded Polystyrene (XPS) sheets have proven to be a high-performance insulation solution for modern construction projects. With their superior thermal efficiency, strength, and moisture resistance, they ensure long-term energy savings and structural protection.

Whether for roofing, flooring, or foundation insulation, XPS insulation boards deliver consistent performance in all environments. Their combination of durability, energy efficiency, and sustainability makes them an ideal choice for architects, builders, and homeowners seeking reliable insulation.

If you are looking for premium-quality extruded polystyrene sheets for your next project, choose a trusted manufacturer offering tested and certified products that meet international standards.