Waterproofing Membrane Installation Overview | Complete Guide for Long-Lasting Protection

Introduction to Waterproofing Membranes

Waterproofing membrane installation is a critical process in modern construction that ensures long-term protection of buildings against water ingress, leakage, and moisture-related damage.

As structures are continuously exposed to rain, groundwater, humidity, and temperature variations, effective waterproofing is essential to maintain structural integrity and indoor comfort.

Waterproofing membranes act as protective barriers that prevent water penetration into concrete, masonry, and structural components.

When installed correctly, these membranes significantly increase the lifespan of buildings and reduce costly repairs caused by dampness, corrosion, and structural weakening.

This overview explains waterproofing membrane systems, types, installation methods, applications, benefits, and best practices in detail.

What Is a Waterproofing Membrane?

A waterproofing membrane is a thin layer of water-resistant or waterproof material applied to surfaces to prevent water penetration.

It can be applied in liquid or sheet form and becomes an integral part of the building envelope.

Purpose of Waterproofing Membranes

-

Prevent water leakage and seepage

-

Protect structural elements from moisture damage

-

Enhance durability of concrete and masonry

-

Improve building performance and safety

-

Reduce maintenance and repair costs

Waterproofing membranes are widely used in residential, commercial, and industrial construction projects.

Importance of Waterproofing Membrane Installation

Improper or missing waterproofing is one of the main causes of building deterioration.

Water infiltration can lead to corrosion of reinforcement steel, concrete spalling, mold growth, and unhealthy indoor conditions.

Key Benefits of Proper Installation

-

Long-term water protection

-

Improved structural durability

-

Enhanced resistance to cracks and movement

-

Increased property value

-

Lower life-cycle costs

Correct installation is as important as selecting the right membrane material.

Types of Waterproofing Membranes

Waterproofing membranes are categorized based on material type, application method, and performance characteristics.

Sheet Waterproofing Membranes

Sheet membranes are factory-manufactured rolls that are applied to surfaces using adhesives, heat welding, or mechanical fixing.

Common Sheet Membrane Types

-

Bituminous membranes

-

PVC membranes

-

EPDM rubber membranes

-

TPO membranes

Advantages

-

Uniform thickness

-

High durability

-

Factory-controlled quality

Limitations

-

Requires skilled installation

-

Joints and overlaps must be sealed properly

Sheet membranes are commonly used for basements, foundations, roofs, and tunnels.

Liquid-Applied Waterproofing Membranes

Liquid membranes are applied in fluid form and cure into seamless, flexible coatings.

Characteristics

-

Seamless and joint-free

-

Excellent crack-bridging ability

-

Easy application on complex surfaces

Common Types

-

Polyurethane membranes

-

Acrylic membranes

-

Bituminous liquid membranes

-

Cementitious coatings

Liquid membranes are ideal for roofs, balconies, wet areas, and irregular surfaces.

Cementitious Waterproofing Membranes

Cementitious membranes are cement-based coatings mixed with polymers or additives.

Features

-

Easy application

-

Good adhesion to concrete

-

Suitable for internal wet areas

Typical Applications

-

Water tanks

-

Bathrooms

-

Basements

They offer limited flexibility and are best suited for areas with minimal structural movement.

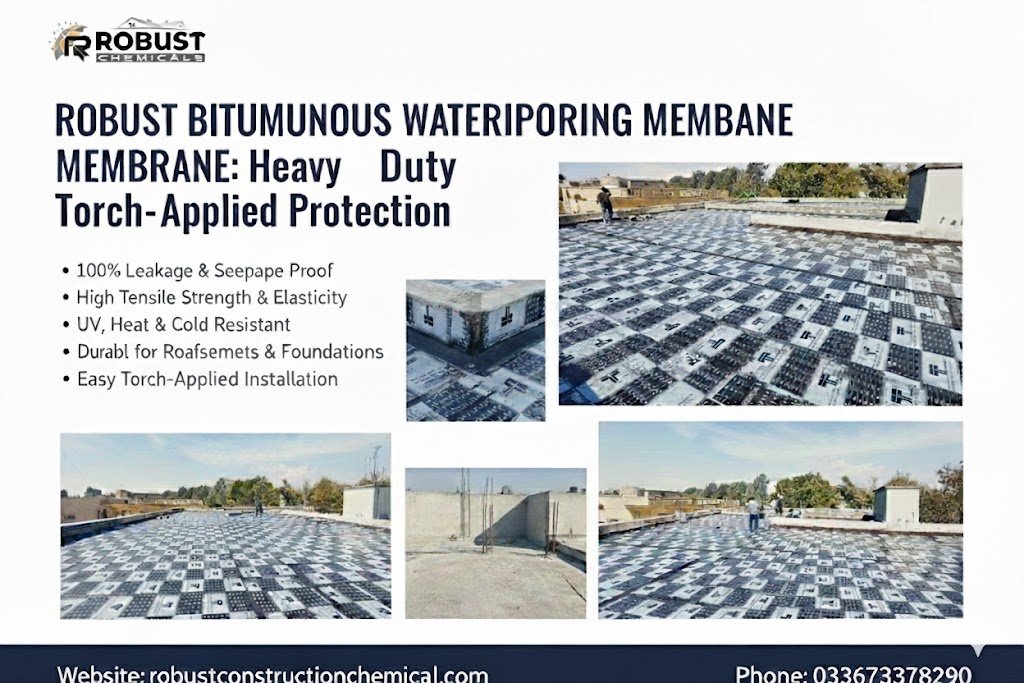

Bituminous Waterproofing Membranes

Bituminous membranes are widely used due to their water resistance and affordability.

Forms

-

Torch-applied membranes

-

Cold-applied membranes

-

Self-adhesive membranes

Benefits

-

High water resistance

-

Suitable for underground structures

Proper protection layers are required to prevent UV damage.

Areas Requiring Waterproofing Membranes

Waterproofing membranes are used across various parts of a structure.

Roofs and Terraces

Prevent rainwater penetration and protect roof slabs.

Basements and Foundations

Protect against groundwater pressure and soil moisture.

Bathrooms and Wet Areas

Prevent seepage into walls and slabs.

Water Tanks and Pools

Ensure water retention and prevent leakage.

Balconies and Podiums

Protect exposed surfaces from weather damage.

Surface Preparation for Waterproofing Membrane Installation

Surface preparation is a critical step that directly impacts membrane performance.

Cleaning the Surface

-

Remove dust, oil, grease, and loose materials

-

Ensure a clean and dry substrate

Repairing Defects

-

Fill cracks and honeycombs

-

Repair damaged concrete

Surface Leveling

-

Smooth uneven surfaces

-

Ensure proper slopes for drainage

Poor surface preparation can lead to membrane failure.

Priming Before Membrane Application

Primers improve adhesion between the substrate and membrane.

Purpose of Primers

-

Enhance bonding

-

Seal porous surfaces

-

Improve membrane durability

Priming requirements depend on membrane type and substrate condition.

Waterproofing Membrane Installation Methods

Different membranes require different installation techniques.

Sheet Membrane Installation Process

Step 1: Surface Inspection

Ensure the surface is clean, dry, and structurally sound.

Step 2: Membrane Placement

Lay the membrane sheets according to layout planning.

Step 3: Joint Sealing

Seal overlaps using heat welding, adhesives, or tapes.

Step 4: Protection Layer

Apply protective screed or boards where required.

Liquid Membrane Installation Process

Step 1: Surface Preparation

Clean and repair the substrate thoroughly.

Step 2: Primer Application

Apply primer if recommended and allow it to dry.

Step 3: First Coat Application

Apply liquid membrane using brush, roller, or spray.

Step 4: Reinforcement

Embed fabric or mesh at joints and corners if required.

Step 5: Second Coat

Apply additional coats to achieve required thickness.

Step 6: Curing

Allow sufficient curing time before exposure.

Thickness and Coverage Control

Maintaining proper membrane thickness is essential.

-

Insufficient thickness reduces performance

-

Excessive thickness may cause cracking

-

Uniform application ensures durability

Manufacturers specify recommended coverage rates.

Detailing in Waterproofing Membrane Installation

Detailing is the most critical part of waterproofing.

Corners and Junctions

Extra reinforcement is required at corners and joints.

Pipe Penetrations

Sealing around pipes prevents leakage points.

Expansion Joints

Flexible detailing allows movement without failure.

Proper detailing ensures long-term waterproofing success.

Quality Control During Installation

Quality control measures help ensure system performance.

Visual Inspection

Check for pinholes, gaps, and uneven coating.

Thickness Measurement

Ensure membrane meets specified thickness.

Water Testing

Ponding tests verify waterproofing integrity.

Common Waterproofing Membrane Installation Mistakes

-

Applying on wet surfaces

-

Poor joint sealing

-

Inadequate curing time

-

Ignoring movement joints

Avoiding these mistakes improves reliability and lifespan.

Waterproofing Membrane Protection Systems

Membranes often require protection from mechanical damage.

Protection Methods

-

Screeds

-

Protection boards

-

Tiles or finishes

Protection layers extend membrane service life.

Maintenance of Waterproofing Membranes

Regular maintenance ensures continued performance.

Inspection

Periodic checks identify early issues.

Cleaning

Remove debris and standing water.

Repairs

Minor damages should be repaired promptly.

Well-maintained membranes can last for decades.

Cost Considerations in Waterproofing Membrane Installation

Costs depend on:

-

Membrane type

-

Area size

-

Surface condition

-

Labor and detailing complexity

While high-quality membranes may cost more initially, they reduce long-term repair expenses.

Environmental and Safety Considerations

Modern waterproofing membranes are designed to be safer and more sustainable.

-

Low VOC formulations

-

Reduced material waste

-

Improved durability

Safe handling and application practices are essential.

Choosing the Right Waterproofing Membrane System

Selection should be based on:

-

Exposure conditions

-

Structural movement

-

Water pressure

-

Project requirements

Consulting waterproofing professionals ensures correct system selection.

Role of Waterproofing Membranes in Modern Construction

Waterproofing membranes are essential for sustainable and durable buildings.

They protect structures, enhance comfort, and reduce long-term costs.

With increasing focus on building performance and durability, membrane waterproofing has become a standard construction requirement.

Future Trends in Waterproofing Membrane Installation

-

Advanced polymer membranes

-

Faster curing technologies

-

Improved flexibility and durability

-

Sustainable waterproofing solutions

These innovations continue to improve waterproofing performance.

Waterproofing Membrane Installation Overview | Complete Guide for Long-Lasting Protection

Introduction to Waterproofing Membranes

Waterproofing membrane installation is a critical process in modern construction that ensures long-term protection of buildings against water ingress, leakage, and moisture-related damage.

As structures are continuously exposed to rain, groundwater, humidity, and temperature variations, effective waterproofing is essential to maintain structural integrity and indoor comfort.

Waterproofing membranes act as protective barriers that prevent water penetration into concrete, masonry, and structural components.

When installed correctly, these membranes significantly increase the lifespan of buildings and reduce costly repairs caused by dampness, corrosion, and structural weakening.

This overview explains waterproofing membrane systems, types, installation methods, applications, benefits, and best practices in detail.

What Is a Waterproofing Membrane?

A waterproofing membrane is a thin layer of water-resistant or waterproof material applied to surfaces to prevent water penetration.

It can be applied in liquid or sheet form and becomes an integral part of the building envelope.

Purpose of Waterproofing Membranes

-

Prevent water leakage and seepage

-

Protect structural elements from moisture damage

-

Enhance durability of concrete and masonry

-

Improve building performance and safety

-

Reduce maintenance and repair costs

Waterproofing membranes are widely used in residential, commercial, and industrial construction projects.

Importance of Waterproofing Membrane Installation

Improper or missing waterproofing is one of the main causes of building deterioration.

Water infiltration can lead to corrosion of reinforcement steel, concrete spalling, mold growth, and unhealthy indoor conditions.

Key Benefits of Proper Installation

-

Long-term water protection

-

Improved structural durability

-

Enhanced resistance to cracks and movement

-

Increased property value

-

Lower life-cycle costs

Correct installation is as important as selecting the right membrane material.

Types of Waterproofing Membranes

Waterproofing membranes are categorized based on material type, application method, and performance characteristics.

Sheet Waterproofing Membranes

Sheet membranes are factory-manufactured rolls that are applied to surfaces using adhesives, heat welding, or mechanical fixing.

Common Sheet Membrane Types

-

Bituminous membranes

-

PVC membranes

-

EPDM rubber membranes

-

TPO membranes

Advantages

-

Uniform thickness

-

High durability

-

Factory-controlled quality

Limitations

-

Requires skilled installation

-

Joints and overlaps must be sealed properly

Sheet membranes are commonly used for basements, foundations, roofs, and tunnels.

Liquid-Applied Waterproofing Membranes

Liquid membranes are applied in fluid form and cure into seamless, flexible coatings.

Characteristics

-

Seamless and joint-free

-

Excellent crack-bridging ability

-

Easy application on complex surfaces

Common Types

-

Polyurethane membranes

-

Acrylic membranes

-

Bituminous liquid membranes

-

Cementitious coatings

Liquid membranes are ideal for roofs, balconies, wet areas, and irregular surfaces.

Cementitious Waterproofing Membranes

Cementitious membranes are cement-based coatings mixed with polymers or additives.

Features

-

Easy application

-

Good adhesion to concrete

-

Suitable for internal wet areas

Typical Applications

-

Water tanks

-

Bathrooms

-

Basements

They offer limited flexibility and are best suited for areas with minimal structural movement.

Bituminous Waterproofing Membranes

Bituminous membranes are widely used due to their water resistance and affordability.

Forms

-

Torch-applied membranes

-

Cold-applied membranes

-

Self-adhesive membranes

Benefits

-

High water resistance

-

Suitable for underground structures

Proper protection layers are required to prevent UV damage.

Areas Requiring Waterproofing Membranes

Waterproofing membranes are used across various parts of a structure.

Roofs and Terraces

Prevent rainwater penetration and protect roof slabs.

Basements and Foundations

Protect against groundwater pressure and soil moisture.

Bathrooms and Wet Areas

Prevent seepage into walls and slabs.

Water Tanks and Pools

Ensure water retention and prevent leakage.

Balconies and Podiums

Protect exposed surfaces from weather damage.

Surface Preparation for Waterproofing Membrane Installation

Surface preparation is a critical step that directly impacts membrane performance.

Cleaning the Surface

-

Remove dust, oil, grease, and loose materials

-

Ensure a clean and dry substrate

Repairing Defects

-

Fill cracks and honeycombs

-

Repair damaged concrete

Surface Leveling

-

Smooth uneven surfaces

-

Ensure proper slopes for drainage

Poor surface preparation can lead to membrane failure.

Priming Before Membrane Application

Primers improve adhesion between the substrate and membrane.

Purpose of Primers

-

Enhance bonding

-

Seal porous surfaces

-

Improve membrane durability

Priming requirements depend on membrane type and substrate condition.

Waterproofing Membrane Installation Methods

Different membranes require different installation techniques.

Sheet Membrane Installation Process

Step 1: Surface Inspection

Ensure the surface is clean, dry, and structurally sound.

Step 2: Membrane Placement

Lay the membrane sheets according to layout planning.

Step 3: Joint Sealing

Seal overlaps using heat welding, adhesives, or tapes.

Step 4: Protection Layer

Apply protective screed or boards where required.

Liquid Membrane Installation Process

Step 1: Surface Preparation

Clean and repair the substrate thoroughly.

Step 2: Primer Application

Apply primer if recommended and allow it to dry.

Step 3: First Coat Application

Apply liquid membrane using brush, roller, or spray.

Step 4: Reinforcement

Embed fabric or mesh at joints and corners if required.

Step 5: Second Coat

Apply additional coats to achieve required thickness.

Step 6: Curing

Allow sufficient curing time before exposure.

Thickness and Coverage Control

Maintaining proper membrane thickness is essential.

-

Insufficient thickness reduces performance

-

Excessive thickness may cause cracking

-

Uniform application ensures durability

Manufacturers specify recommended coverage rates.

Detailing in Waterproofing Membrane Installation

Detailing is the most critical part of waterproofing.

Corners and Junctions

Extra reinforcement is required at corners and joints.

Pipe Penetrations

Sealing around pipes prevents leakage points.

Expansion Joints

Flexible detailing allows movement without failure.

Proper detailing ensures long-term waterproofing success.

Quality Control During Installation

Quality control measures help ensure system performance.

Visual Inspection

Check for pinholes, gaps, and uneven coating.

Thickness Measurement

Ensure membrane meets specified thickness.

Water Testing

Ponding tests verify waterproofing integrity.

Common Waterproofing Membrane Installation Mistakes

-

Applying on wet surfaces

-

Poor joint sealing

-

Inadequate curing time

-

Ignoring movement joints

Avoiding these mistakes improves reliability and lifespan.

Waterproofing Membrane Protection Systems

Membranes often require protection from mechanical damage.

Protection Methods

-

Screeds

-

Protection boards

-

Tiles or finishes

Protection layers extend membrane service life.

Maintenance of Waterproofing Membranes

Regular maintenance ensures continued performance.

Inspection

Periodic checks identify early issues.

Cleaning

Remove debris and standing water.

Repairs

Minor damages should be repaired promptly.

Well-maintained membranes can last for decades.

Cost Considerations in Waterproofing Membrane Installation

Costs depend on:

-

Membrane type

-

Area size

-

Surface condition

-

Labor and detailing complexity

While high-quality membranes may cost more initially, they reduce long-term repair expenses.

Environmental and Safety Considerations

Modern waterproofing membranes are designed to be safer and more sustainable.

-

Low VOC formulations

-

Reduced material waste

-

Improved durability

Safe handling and application practices are essential.

Choosing the Right Waterproofing Membrane System

Selection should be based on:

-

Exposure conditions

-

Structural movement

-

Water pressure

-

Project requirements

Consulting waterproofing professionals ensures correct system selection.

Role of Waterproofing Membranes in Modern Construction

Waterproofing membranes are essential for sustainable and durable buildings.

They protect structures, enhance comfort, and reduce long-term costs.

With increasing focus on building performance and durability, membrane waterproofing has become a standard construction requirement.

Future Trends in Waterproofing Membrane Installation

-

Advanced polymer membranes

-

Faster curing technologies

-

Improved flexibility and durability

-

Sustainable waterproofing solutions

These innovations continue to improve waterproofing performance.

Waterproofing Membrane Installation Overview | Complete Guide for Long-Lasting Protection

Introduction to Waterproofing Membranes

Waterproofing membrane installation is a critical process in modern construction that ensures long-term protection of buildings against water ingress, leakage, and moisture-related damage.

As structures are continuously exposed to rain, groundwater, humidity, and temperature variations, effective waterproofing is essential to maintain structural integrity and indoor comfort.

Waterproofing membranes act as protective barriers that prevent water penetration into concrete, masonry, and structural components.

When installed correctly, these membranes significantly increase the lifespan of buildings and reduce costly repairs caused by dampness, corrosion, and structural weakening.

This overview explains waterproofing membrane systems, types, installation methods, applications, benefits, and best practices in detail.

What Is a Waterproofing Membrane?

A waterproofing membrane is a thin layer of water-resistant or waterproof material applied to surfaces to prevent water penetration.

It can be applied in liquid or sheet form and becomes an integral part of the building envelope.

Purpose of Waterproofing Membranes

-

Prevent water leakage and seepage

-

Protect structural elements from moisture damage

-

Enhance durability of concrete and masonry

-

Improve building performance and safety

-

Reduce maintenance and repair costs

Waterproofing membranes are widely used in residential, commercial, and industrial construction projects.

Importance of Waterproofing Membrane Installation

Improper or missing waterproofing is one of the main causes of building deterioration.

Water infiltration can lead to corrosion of reinforcement steel, concrete spalling, mold growth, and unhealthy indoor conditions.

Key Benefits of Proper Installation

-

Long-term water protection

-

Improved structural durability

-

Enhanced resistance to cracks and movement

-

Increased property value

-

Lower life-cycle costs

Correct installation is as important as selecting the right membrane material.

Types of Waterproofing Membranes

Waterproofing membranes are categorized based on material type, application method, and performance characteristics.

Sheet Waterproofing Membranes

Sheet membranes are factory-manufactured rolls that are applied to surfaces using adhesives, heat welding, or mechanical fixing.

Common Sheet Membrane Types

-

Bituminous membranes

-

PVC membranes

-

EPDM rubber membranes

-

TPO membranes

Advantages

-

Uniform thickness

-

High durability

-

Factory-controlled quality

Limitations

-

Requires skilled installation

-

Joints and overlaps must be sealed properly

Sheet membranes are commonly used for basements, foundations, roofs, and tunnels.

Liquid-Applied Waterproofing Membranes

Liquid membranes are applied in fluid form and cure into seamless, flexible coatings.

Characteristics

-

Seamless and joint-free

-

Excellent crack-bridging ability

-

Easy application on complex surfaces

Common Types

-

Polyurethane membranes

-

Acrylic membranes

-

Bituminous liquid membranes

-

Cementitious coatings

Liquid membranes are ideal for roofs, balconies, wet areas, and irregular surfaces.

Cementitious Waterproofing Membranes

Cementitious membranes are cement-based coatings mixed with polymers or additives.

Features

-

Easy application

-

Good adhesion to concrete

-

Suitable for internal wet areas

Typical Applications

-

Water tanks

-

Bathrooms

-

Basements

They offer limited flexibility and are best suited for areas with minimal structural movement.

Bituminous Waterproofing Membranes

Bituminous membranes are widely used due to their water resistance and affordability.

Forms

-

Torch-applied membranes

-

Cold-applied membranes

-

Self-adhesive membranes

Benefits

-

High water resistance

-

Suitable for underground structures

Proper protection layers are required to prevent UV damage.

Areas Requiring Waterproofing Membranes

Waterproofing membranes are used across various parts of a structure.

Roofs and Terraces

Prevent rainwater penetration and protect roof slabs.

Basements and Foundations

Protect against groundwater pressure and soil moisture.

Bathrooms and Wet Areas

Prevent seepage into walls and slabs.

Water Tanks and Pools

Ensure water retention and prevent leakage.

Balconies and Podiums

Protect exposed surfaces from weather damage.

Surface Preparation for Waterproofing Membrane Installation

Surface preparation is a critical step that directly impacts membrane performance.

Cleaning the Surface

-

Remove dust, oil, grease, and loose materials

-

Ensure a clean and dry substrate

Repairing Defects

-

Fill cracks and honeycombs

-

Repair damaged concrete

Surface Leveling

-

Smooth uneven surfaces

-

Ensure proper slopes for drainage

Poor surface preparation can lead to membrane failure.

Priming Before Membrane Application

Primers improve adhesion between the substrate and membrane.

Purpose of Primers

-

Enhance bonding

-

Seal porous surfaces

-

Improve membrane durability

Priming requirements depend on membrane type and substrate condition.

Waterproofing Membrane Installation Methods

Different membranes require different installation techniques.

Sheet Membrane Installation Process

Step 1: Surface Inspection

Ensure the surface is clean, dry, and structurally sound.

Step 2: Membrane Placement

Lay the membrane sheets according to layout planning.

Step 3: Joint Sealing

Seal overlaps using heat welding, adhesives, or tapes.

Step 4: Protection Layer

Apply protective screed or boards where required.

Liquid Membrane Installation Process

Step 1: Surface Preparation

Clean and repair the substrate thoroughly.

Step 2: Primer Application

Apply primer if recommended and allow it to dry.

Step 3: First Coat Application

Apply liquid membrane using brush, roller, or spray.

Step 4: Reinforcement

Embed fabric or mesh at joints and corners if required.

Step 5: Second Coat

Apply additional coats to achieve required thickness.

Step 6: Curing

Allow sufficient curing time before exposure.

Thickness and Coverage Control

Maintaining proper membrane thickness is essential.

-

Insufficient thickness reduces performance

-

Excessive thickness may cause cracking

-

Uniform application ensures durability

Manufacturers specify recommended coverage rates.

Detailing in Waterproofing Membrane Installation

Detailing is the most critical part of waterproofing.

Corners and Junctions

Extra reinforcement is required at corners and joints.

Pipe Penetrations

Sealing around pipes prevents leakage points.

Expansion Joints

Flexible detailing allows movement without failure.

Proper detailing ensures long-term waterproofing success.

Quality Control During Installation

Quality control measures help ensure system performance.

Visual Inspection

Check for pinholes, gaps, and uneven coating.

Thickness Measurement

Ensure membrane meets specified thickness.

Water Testing

Ponding tests verify waterproofing integrity.

Common Waterproofing Membrane Installation Mistakes

-

Applying on wet surfaces

-

Poor joint sealing

-

Inadequate curing time

-

Ignoring movement joints

Avoiding these mistakes improves reliability and lifespan.

Waterproofing Membrane Protection Systems

Membranes often require protection from mechanical damage.

Protection Methods

-

Screeds

-

Protection boards

-

Tiles or finishes

Protection layers extend membrane service life.

Maintenance of Waterproofing Membranes

Regular maintenance ensures continued performance.

Inspection

Periodic checks identify early issues.

Cleaning

Remove debris and standing water.

Repairs

Minor damages should be repaired promptly.

Well-maintained membranes can last for decades.

Cost Considerations in Waterproofing Membrane Installation

Costs depend on:

-

Membrane type

-

Area size

-

Surface condition

-

Labor and detailing complexity

While high-quality membranes may cost more initially, they reduce long-term repair expenses.

Environmental and Safety Considerations

Modern waterproofing membranes are designed to be safer and more sustainable.

-

Low VOC formulations

-

Reduced material waste

-

Improved durability

Safe handling and application practices are essential.

Choosing the Right Waterproofing Membrane System

Selection should be based on:

-

Exposure conditions

-

Structural movement

-

Water pressure

-

Project requirements

Consulting waterproofing professionals ensures correct system selection.

Role of Waterproofing Membranes in Modern Construction

Waterproofing membranes are essential for sustainable and durable buildings.

They protect structures, enhance comfort, and reduce long-term costs.

With increasing focus on building performance and durability, membrane waterproofing has become a standard construction requirement.

Future Trends in Waterproofing Membrane Installation

-

Advanced polymer membranes

-

Faster curing technologies

-

Improved flexibility and durability

-

Sustainable waterproofing solutions

These innovations continue to improve waterproofing performance.