Professional PU Liquid Rubber | Waterproofing & Crack Prevention for Residential & Industrial Projects

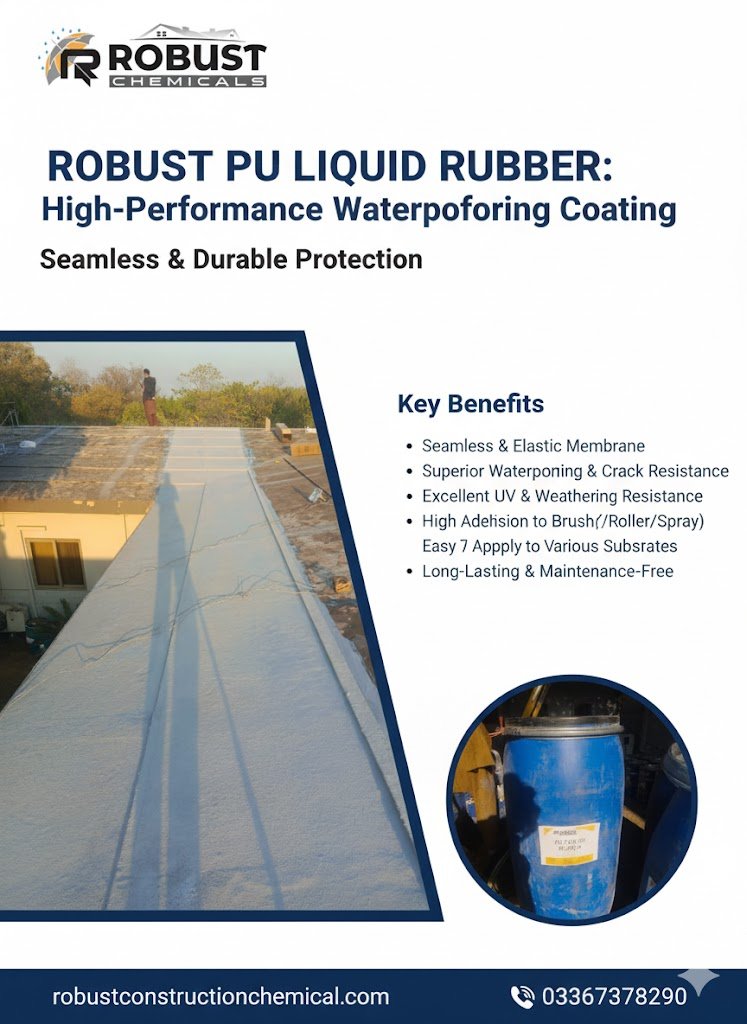

PU Liquid Rubber is a high-performance, polyurethane-based waterproofing and crack-prevention solution designed to deliver long-lasting protection for residential, commercial, and industrial construction projects.

Renowned for its flexibility, durability, and seamless adhesion, PU Liquid Rubber provides a highly effective barrier against water infiltration, chemical damage, and environmental stressors.

Its superior performance makes it ideal for roofs, terraces, basements, water tanks, balconies, and other structural surfaces where long-term waterproofing and crack resistance are critical.

Contractors, builders, and property owners across Pakistan, particularly in cities like Lahore, Karachi, Islamabad, Rawalpindi, and Faisalabad, rely on PU Liquid Rubber to safeguard structural integrity, enhance durability, and reduce maintenance costs over time.

In residential construction, PU Liquid Rubber provides a reliable solution for waterproofing roofs, terraces, bathrooms, kitchens, and basements. Its seamless, elastic membrane prevents water leaks, dampness, and moisture-related damage, ensuring the longevity of building surfaces.

Homeowners benefit from its ability to accommodate structural movements and thermal expansion without cracking, peeling, or delaminating.

The chemical’s flexibility allows it to bridge hairline cracks and minor imperfections, creating a smooth, even surface that maintains its protective properties over years of exposure to sun, rain, and temperature fluctuations.

PU Liquid Rubber also enhances the aesthetic appeal of residential surfaces by providing a uniform, durable finish suitable for painting or further coatings.

In industrial and commercial applications, PU Liquid Rubber offers exceptional durability and chemical resistance.

Its robust performance makes it suitable for warehouses, factories, storage facilities, laboratories, and industrial floors that are exposed to heavy traffic, mechanical stress, and chemical spills.

The polyurethane formulation creates a dense, resilient membrane that resists abrasion, impact, and chemical degradation, ensuring continuous protection for critical infrastructure.

Its seamless application reduces maintenance requirements, prevents structural deterioration, and provides a cost-effective solution for large-scale projects. Facility managers and industrial contractors value PU Liquid Rubber for its long-term reliability and adaptability to demanding environments.

The crack-prevention properties of PU Liquid Rubber are a key advantage in both new construction and repair projects.

By forming a flexible membrane over cementitious, concrete, or masonry substrates, it bridges minor cracks and prevents the development of new fissures caused by shrinkage, settlement, or structural movement.

In repair applications, PU Liquid Rubber can be applied to damaged roofs, basements, or walls to restore waterproofing integrity, strengthen weak areas, and prevent recurring leaks. Its ability to adhere strongly to various substrates ensures effective reinforcement and long-lasting protection, minimizing future maintenance and repair costs.

PU Liquid Rubber is highly versatile and compatible with a wide range of construction materials, including concrete, cement, masonry, metals, and polymer-modified surfaces.

Its two-component or single-component formulations (depending on the product specification) allow for precise application tailored to project requirements.

The liquid consistency enables it to penetrate pores, irregularities, and minor imperfections in the substrate, ensuring full coverage and seamless waterproofing. After curing, PU Liquid Rubber forms a durable, elastic membrane that withstands mechanical stress, thermal cycles, UV exposure, and environmental degradation.

From a technical perspective, PU Liquid Rubber offers excellent adhesion, elongation, and flexibility.

These properties allow the membrane to expand and contract with structural movements without compromising the waterproofing layer. Its chemical resistance protects surfaces from acidic or alkaline conditions, oils, solvents, and other corrosive substances commonly encountered in industrial and commercial environments.

PU Liquid Rubber also provides thermal and UV stability, ensuring long-lasting performance under varying climatic conditions prevalent in Pakistan.

For contractors and applicators, PU Liquid Rubber offers ease of application and professional-grade results.

Surface preparation is key: the substrate must be clean, dry, and free from dust, oils, or loose particles. Cracks and voids are repaired prior to application to ensure optimal adhesion. The product is then applied using brushes, rollers, squeegees, or spray equipment, depending on the project size and accessibility.

The liquid flows and self-levels into a smooth, uniform coating, creating a continuous, seamless membrane that requires minimal maintenance after curing. Proper mixing and application according to manufacturer guidelines are essential for achieving maximum performance and durability.

Economically, PU Liquid Rubber is a cost-effective solution when considering its long-term benefits. By providing reliable waterproofing and crack prevention, it minimizes the need for frequent repairs and replacements, saving both labor and material costs over the life of the structure.

Its durability, chemical resistance, and flexibility ensure that surfaces remain protected for extended periods, providing an excellent return on investment for residential, commercial, and industrial projects.

Environmentally, PU Liquid Rubber contributes to sustainable construction practices.

Its long-lasting nature reduces material waste, and many modern formulations are low in volatile organic compounds (VOCs), promoting healthier indoor air quality.

The seamless, non-porous surface prevents water and chemical ingress, reducing the environmental impact of repair cycles and material degradation. Additionally, its reflective and smooth finish can improve energy efficiency in building surfaces by minimizing heat absorption and reducing the load on cooling systems.

PU Liquid Rubber is suitable for a wide range of construction projects. In residential buildings, it provides reliable waterproofing for terraces, roofs, basements, and bathrooms.

in commercial and industrial facilities, it strengthens concrete floors, storage tanks, water reservoirs, and structural elements while preventing leaks and chemical damage. Its versatility, durability, and professional-grade performance make it an essential product for contractors, builders, and engineers seeking effective, long-lasting solutions for waterproofing and crack prevention.

In Pakistan, the growing demand for PU Liquid Rubber reflects the increasing awareness of high-quality, durable, and reliable construction materials.

Builders and contractors in urban and industrial centers such as Lahore, Karachi, Islamabad, Rawalpindi, and Faisalabad rely on PU Liquid Rubber to deliver professional results, protect structures from water damage, and ensure long-term durability.

Its adaptability, ease of application, and proven performance make it a preferred choice for modern construction projects across residential, commercial, and industrial sectors.

In conclusion, PU Liquid Rubber is a professional-grade, high-performance waterproofing and crack-prevention solution suitable for residential, commercial, and industrial applications.

Its flexibility, durability, seamless adhesion, and chemical resistance provide long-lasting protection for roofs, basements, terraces, water tanks, and structural surfaces.

By using PU Liquid Rubber, property owners, contractors, and construction professionals can achieve reliable, cost-effective, and sustainable solutions that ensure structural integrity, reduce maintenance, and enhance the overall longevity of construction projects.

Professional PU Liquid Rubber | Waterproofing & Crack Prevention for Residential & Industrial Projects

PU Liquid Rubber is a high-performance, polyurethane-based waterproofing and crack-prevention solution designed to deliver long-lasting protection for residential, commercial, and industrial construction projects.

Renowned for its flexibility, durability, and seamless adhesion, PU Liquid Rubber provides a highly effective barrier against water infiltration, chemical damage, and environmental stressors.

Its superior performance makes it ideal for roofs, terraces, basements, water tanks, balconies, and other structural surfaces where long-term waterproofing and crack resistance are critical.

Contractors, builders, and property owners across Pakistan, particularly in cities like Lahore, Karachi, Islamabad, Rawalpindi, and Faisalabad, rely on PU Liquid Rubber to safeguard structural integrity, enhance durability, and reduce maintenance costs over time.

In residential construction, PU Liquid Rubber provides a reliable solution for waterproofing roofs, terraces, bathrooms, kitchens, and basements. Its seamless, elastic membrane prevents water leaks, dampness, and moisture-related damage, ensuring the longevity of building surfaces.

Homeowners benefit from its ability to accommodate structural movements and thermal expansion without cracking, peeling, or delaminating.

The chemical’s flexibility allows it to bridge hairline cracks and minor imperfections, creating a smooth, even surface that maintains its protective properties over years of exposure to sun, rain, and temperature fluctuations.

PU Liquid Rubber also enhances the aesthetic appeal of residential surfaces by providing a uniform, durable finish suitable for painting or further coatings.

In industrial and commercial applications, PU Liquid Rubber offers exceptional durability and chemical resistance.

Its robust performance makes it suitable for warehouses, factories, storage facilities, laboratories, and industrial floors that are exposed to heavy traffic, mechanical stress, and chemical spills.

The polyurethane formulation creates a dense, resilient membrane that resists abrasion, impact, and chemical degradation, ensuring continuous protection for critical infrastructure.

Its seamless application reduces maintenance requirements, prevents structural deterioration, and provides a cost-effective solution for large-scale projects. Facility managers and industrial contractors value PU Liquid Rubber for its long-term reliability and adaptability to demanding environments.

The crack-prevention properties of PU Liquid Rubber are a key advantage in both new construction and repair projects.

By forming a flexible membrane over cementitious, concrete, or masonry substrates, it bridges minor cracks and prevents the development of new fissures caused by shrinkage, settlement, or structural movement.

In repair applications, PU Liquid Rubber can be applied to damaged roofs, basements, or walls to restore waterproofing integrity, strengthen weak areas, and prevent recurring leaks. Its ability to adhere strongly to various substrates ensures effective reinforcement and long-lasting protection, minimizing future maintenance and repair costs.

PU Liquid Rubber is highly versatile and compatible with a wide range of construction materials, including concrete, cement, masonry, metals, and polymer-modified surfaces.

Its two-component or single-component formulations (depending on the product specification) allow for precise application tailored to project requirements.

The liquid consistency enables it to penetrate pores, irregularities, and minor imperfections in the substrate, ensuring full coverage and seamless waterproofing. After curing, PU Liquid Rubber forms a durable, elastic membrane that withstands mechanical stress, thermal cycles, UV exposure, and environmental degradation.

From a technical perspective, PU Liquid Rubber offers excellent adhesion, elongation, and flexibility.

These properties allow the membrane to expand and contract with structural movements without compromising the waterproofing layer. Its chemical resistance protects surfaces from acidic or alkaline conditions, oils, solvents, and other corrosive substances commonly encountered in industrial and commercial environments.

PU Liquid Rubber also provides thermal and UV stability, ensuring long-lasting performance under varying climatic conditions prevalent in Pakistan.

For contractors and applicators, PU Liquid Rubber offers ease of application and professional-grade results.

Surface preparation is key: the substrate must be clean, dry, and free from dust, oils, or loose particles. Cracks and voids are repaired prior to application to ensure optimal adhesion. The product is then applied using brushes, rollers, squeegees, or spray equipment, depending on the project size and accessibility.

The liquid flows and self-levels into a smooth, uniform coating, creating a continuous, seamless membrane that requires minimal maintenance after curing. Proper mixing and application according to manufacturer guidelines are essential for achieving maximum performance and durability.

Economically, PU Liquid Rubber is a cost-effective solution when considering its long-term benefits. By providing reliable waterproofing and crack prevention, it minimizes the need for frequent repairs and replacements, saving both labor and material costs over the life of the structure.

Its durability, chemical resistance, and flexibility ensure that surfaces remain protected for extended periods, providing an excellent return on investment for residential, commercial, and industrial projects.

Environmentally, PU Liquid Rubber contributes to sustainable construction practices.

Its long-lasting nature reduces material waste, and many modern formulations are low in volatile organic compounds (VOCs), promoting healthier indoor air quality.

The seamless, non-porous surface prevents water and chemical ingress, reducing the environmental impact of repair cycles and material degradation. Additionally, its reflective and smooth finish can improve energy efficiency in building surfaces by minimizing heat absorption and reducing the load on cooling systems.

PU Liquid Rubber is suitable for a wide range of construction projects. In residential buildings, it provides reliable waterproofing for terraces, roofs, basements, and bathrooms.

in commercial and industrial facilities, it strengthens concrete floors, storage tanks, water reservoirs, and structural elements while preventing leaks and chemical damage. Its versatility, durability, and professional-grade performance make it an essential product for contractors, builders, and engineers seeking effective, long-lasting solutions for waterproofing and crack prevention.

In Pakistan, the growing demand for PU Liquid Rubber reflects the increasing awareness of high-quality, durable, and reliable construction materials.

Builders and contractors in urban and industrial centers such as Lahore, Karachi, Islamabad, Rawalpindi, and Faisalabad rely on PU Liquid Rubber to deliver professional results, protect structures from water damage, and ensure long-term durability.

Its adaptability, ease of application, and proven performance make it a preferred choice for modern construction projects across residential, commercial, and industrial sectors.

In conclusion, PU Liquid Rubber is a professional-grade, high-performance waterproofing and crack-prevention solution suitable for residential, commercial, and industrial applications.

Its flexibility, durability, seamless adhesion, and chemical resistance provide long-lasting protection for roofs, basements, terraces, water tanks, and structural surfaces.

By using PU Liquid Rubber, property owners, contractors, and construction professionals can achieve reliable, cost-effective, and sustainable solutions that ensure structural integrity, reduce maintenance, and enhance the overall longevity of construction projects.

Professional PU Liquid Rubber | Waterproofing & Crack Prevention for Residential & Industrial Projects

PU Liquid Rubber is a high-performance, polyurethane-based waterproofing and crack-prevention solution designed to deliver long-lasting protection for residential, commercial, and industrial construction projects.

Renowned for its flexibility, durability, and seamless adhesion, PU Liquid Rubber provides a highly effective barrier against water infiltration, chemical damage, and environmental stressors.

Its superior performance makes it ideal for roofs, terraces, basements, water tanks, balconies, and other structural surfaces where long-term waterproofing and crack resistance are critical.

Contractors, builders, and property owners across Pakistan, particularly in cities like Lahore, Karachi, Islamabad, Rawalpindi, and Faisalabad, rely on PU Liquid Rubber to safeguard structural integrity, enhance durability, and reduce maintenance costs over time.

In residential construction, PU Liquid Rubber provides a reliable solution for waterproofing roofs, terraces, bathrooms, kitchens, and basements. Its seamless, elastic membrane prevents water leaks, dampness, and moisture-related damage, ensuring the longevity of building surfaces.

Homeowners benefit from its ability to accommodate structural movements and thermal expansion without cracking, peeling, or delaminating.

The chemical’s flexibility allows it to bridge hairline cracks and minor imperfections, creating a smooth, even surface that maintains its protective properties over years of exposure to sun, rain, and temperature fluctuations.

PU Liquid Rubber also enhances the aesthetic appeal of residential surfaces by providing a uniform, durable finish suitable for painting or further coatings.

In industrial and commercial applications, PU Liquid Rubber offers exceptional durability and chemical resistance.

Its robust performance makes it suitable for warehouses, factories, storage facilities, laboratories, and industrial floors that are exposed to heavy traffic, mechanical stress, and chemical spills.

The polyurethane formulation creates a dense, resilient membrane that resists abrasion, impact, and chemical degradation, ensuring continuous protection for critical infrastructure.

Its seamless application reduces maintenance requirements, prevents structural deterioration, and provides a cost-effective solution for large-scale projects. Facility managers and industrial contractors value PU Liquid Rubber for its long-term reliability and adaptability to demanding environments.

The crack-prevention properties of PU Liquid Rubber are a key advantage in both new construction and repair projects.

By forming a flexible membrane over cementitious, concrete, or masonry substrates, it bridges minor cracks and prevents the development of new fissures caused by shrinkage, settlement, or structural movement.

In repair applications, PU Liquid Rubber can be applied to damaged roofs, basements, or walls to restore waterproofing integrity, strengthen weak areas, and prevent recurring leaks. Its ability to adhere strongly to various substrates ensures effective reinforcement and long-lasting protection, minimizing future maintenance and repair costs.

PU Liquid Rubber is highly versatile and compatible with a wide range of construction materials, including concrete, cement, masonry, metals, and polymer-modified surfaces.

Its two-component or single-component formulations (depending on the product specification) allow for precise application tailored to project requirements.

The liquid consistency enables it to penetrate pores, irregularities, and minor imperfections in the substrate, ensuring full coverage and seamless waterproofing. After curing, PU Liquid Rubber forms a durable, elastic membrane that withstands mechanical stress, thermal cycles, UV exposure, and environmental degradation.

From a technical perspective, PU Liquid Rubber offers excellent adhesion, elongation, and flexibility.

These properties allow the membrane to expand and contract with structural movements without compromising the waterproofing layer. Its chemical resistance protects surfaces from acidic or alkaline conditions, oils, solvents, and other corrosive substances commonly encountered in industrial and commercial environments.

PU Liquid Rubber also provides thermal and UV stability, ensuring long-lasting performance under varying climatic conditions prevalent in Pakistan.

For contractors and applicators, PU Liquid Rubber offers ease of application and professional-grade results.

Surface preparation is key: the substrate must be clean, dry, and free from dust, oils, or loose particles. Cracks and voids are repaired prior to application to ensure optimal adhesion. The product is then applied using brushes, rollers, squeegees, or spray equipment, depending on the project size and accessibility.

The liquid flows and self-levels into a smooth, uniform coating, creating a continuous, seamless membrane that requires minimal maintenance after curing. Proper mixing and application according to manufacturer guidelines are essential for achieving maximum performance and durability.

Economically, PU Liquid Rubber is a cost-effective solution when considering its long-term benefits. By providing reliable waterproofing and crack prevention, it minimizes the need for frequent repairs and replacements, saving both labor and material costs over the life of the structure.

Its durability, chemical resistance, and flexibility ensure that surfaces remain protected for extended periods, providing an excellent return on investment for residential, commercial, and industrial projects.

Environmentally, PU Liquid Rubber contributes to sustainable construction practices.

Its long-lasting nature reduces material waste, and many modern formulations are low in volatile organic compounds (VOCs), promoting healthier indoor air quality.

The seamless, non-porous surface prevents water and chemical ingress, reducing the environmental impact of repair cycles and material degradation. Additionally, its reflective and smooth finish can improve energy efficiency in building surfaces by minimizing heat absorption and reducing the load on cooling systems.

PU Liquid Rubber is suitable for a wide range of construction projects. In residential buildings, it provides reliable waterproofing for terraces, roofs, basements, and bathrooms.

in commercial and industrial facilities, it strengthens concrete floors, storage tanks, water reservoirs, and structural elements while preventing leaks and chemical damage. Its versatility, durability, and professional-grade performance make it an essential product for contractors, builders, and engineers seeking effective, long-lasting solutions for waterproofing and crack prevention.

In Pakistan, the growing demand for PU Liquid Rubber reflects the increasing awareness of high-quality, durable, and reliable construction materials.

Builders and contractors in urban and industrial centers such as Lahore, Karachi, Islamabad, Rawalpindi, and Faisalabad rely on PU Liquid Rubber to deliver professional results, protect structures from water damage, and ensure long-term durability.

Its adaptability, ease of application, and proven performance make it a preferred choice for modern construction projects across residential, commercial, and industrial sectors.

In conclusion, PU Liquid Rubber is a professional-grade, high-performance waterproofing and crack-prevention solution suitable for residential, commercial, and industrial applications.

Its flexibility, durability, seamless adhesion, and chemical resistance provide long-lasting protection for roofs, basements, terraces, water tanks, and structural surfaces.

By using PU Liquid Rubber, property owners, contractors, and construction professionals can achieve reliable, cost-effective, and sustainable solutions that ensure structural integrity, reduce maintenance, and enhance the overall longevity of construction projects.

professionalprofessionalprofessionalprofessionalprofessionalprofessionalprofessionalprofessionalprofessionalprofessionalprofessionalprofessionalprofessionalprofessionalprofessionalprofessionalprofessionalprofessional