Robust Backer Rod | Premium Joint Filling & Sealant Support Solution

Meta Description:

Robust Backer Rod is a high-quality closed-cell polyethylene foam rod designed to control sealant depth, improve joint performance, and provide long-lasting waterproof sealing in construction expansion joints and concrete works.

H2: What is Robust Backer Rod?

Robust Backer Rod is a flexible, compressible foam rod made from closed-cell polyethylene material.

It is installed inside joints before applying sealant to control joint depth, support sealant shape, and prevent three-sided adhesion.

Backer rods are essential in expansion joints, control joints, glazing joints, precast panels, concrete slabs, and façade systems.

They improve sealant performance, extend service life, and reduce material consumption.

H2: Material Composition & Structure

H3: Closed-Cell Polyethylene Foam

Robust Backer Rod is manufactured from high-density polyethylene foam with a closed-cell structure.

This ensures low water absorption, excellent flexibility, and chemical resistance.

H3: Round Uniform Profile

The rod has consistent diameter for uniform joint filling and easy installation.

Maintains compression and shape recovery.

H3: Lightweight and Non-Absorbent

Does not absorb moisture, rot, or degrade.

Safe for indoor and outdoor use.

H2: Key Functions of Robust Backer Rod

H3: Controls Sealant Depth

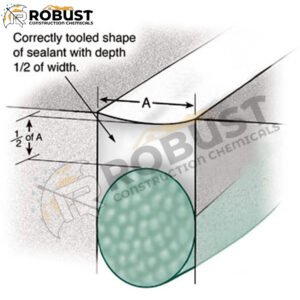

Ensures proper sealant thickness and joint geometry.

Prevents excessive sealant usage and saves cost.

H3: Prevents Three-Sided Adhesion

Allows sealant to bond only on two sides for proper movement.

Prevents premature cracking and failure.

H3: Provides Joint Flexibility

Supports expansion and contraction movement.

Enhances durability of sealant joints.

H3: Acts as Bond Breaker

Prevents sealant from sticking to joint bottom.

H2: Performance Features

H3: Water Resistance

Closed-cell structure prevents water penetration.

H3: Chemical Resistance

Resists oils, acids, alkalis, and construction chemicals.

H3: Temperature Stability

Performs well in hot and cold climates.

H3: Compression Recovery

Maintains shape after compression.

H2: Applications of Robust Backer Rod

H3: Expansion Joints

Concrete slabs, bridges, pavements, basements.

H3: Window & Door Perimeters

Improves sealing performance.

H3: Precast Panels & Facades

Controls joint depth and sealing.

H3: Flooring & Industrial Joints

Supports movement joints.

H3: Roofing & Waterproofing Systems

Enhances joint sealing durability.

H2: Installation Guidelines

H3: Joint Preparation

Clean joint from dust and debris.

H3: Backer Rod Placement

Insert using blunt tool.

H3: Sealant Application

Apply sealant over rod.

H2: Available Sizes

Multiple diameters available.

Custom sizes on request.

H2: Advantages of Robust Backer Rod

-

Improves sealant life

-

Reduces sealant consumption

-

Waterproof and durable

-

Easy installation

-

Cost-effective

-

Chemical resistant

-

Suitable for indoor and outdoor use

H2: Why Choose Robust Backer Rod?

Reliable quality.

Consistent performance.

Trusted by professionals.

H2: Conclusion

Robust Backer Rod ensures professional joint sealing performance, durability, and cost efficiency in all construction applications.

Robust Backer Rod | Advanced Joint Filling & Sealant Support System

Meta Description:

Robust Backer Rod is a premium closed-cell polyethylene foam rod designed to control sealant depth, prevent three-sided adhesion, enhance waterproofing performance, and extend the service life of expansion joints in concrete and construction works.

H2: Introduction to Robust Backer Rod

Robust Backer Rod is a compressible, resilient foam rod used as a joint backing material before sealant application.

It is installed into joints to ensure proper sealant shape, depth control, and long-term movement capability.

Backer rods play a critical role in construction joint systems, allowing sealants to perform correctly by preventing excessive adhesion and providing flexible support.

Robust Backer Rod is trusted in infrastructure projects, commercial buildings, industrial flooring, bridges, basements, and façade systems.

The closed-cell structure ensures moisture resistance, dimensional stability, and durability even under harsh environmental conditions.

H2: Material Composition & Structural Design

H3: Closed-Cell Polyethylene Foam Core

Robust Backer Rod is manufactured from high-density polyethylene foam with millions of sealed microcells.

This structure prevents water absorption and provides excellent compression recovery.

The foam maintains flexibility while resisting permanent deformation.

This ensures consistent joint performance throughout the building lifecycle.

H3: Uniform Cylindrical Profile

Each backer rod is produced with precise diameter tolerance.

This allows consistent joint filling and predictable sealant depth.

Uniform round shape ensures even compression and perfect seating inside joints.

H3: Lightweight & Non-Absorbent Construction

The material is extremely lightweight, simplifying handling and installation.

It does not rot, degrade, or support mold growth.

H2: Functional Role in Joint Sealing Systems

H3: Sealant Depth Control

Backer rods regulate the thickness of applied sealant.

Proper depth ensures optimal elasticity and movement capacity.

Overfilling sealant increases cost and reduces flexibility.

Underfilling reduces durability.

Backer rod ensures correct geometry every time.

H3: Prevention of Three-Sided Adhesion

Sealants must adhere to only two sides of a joint.

Bonding on three sides causes stress concentration and cracking.

Backer rod acts as a bond breaker at the bottom of the joint.

This improves joint movement capability and longevity.

H3: Joint Movement Accommodation

Backer rods allow sealant to expand and contract freely.

This supports thermal movement, structural movement, and vibration.

H3: Sealant Shape Optimization

Creates ideal hourglass sealant profile.

Improves load distribution and elasticity.

H2: Mechanical & Physical Performance

H3: Compression Recovery

Maintains shape after compression.

Ensures permanent joint support.

H3: Tensile Strength & Flexibility

Resists tearing during installation.

Adapts easily to uneven joints.

H3: Temperature Resistance

Performs in extreme hot and cold conditions.

Maintains flexibility in all climates.

H2: Chemical & Environmental Resistance

H3: Moisture Resistance

Zero water absorption prevents deterioration.

Ideal for wet environments.

H3: Chemical Compatibility

Compatible with polyurethane, silicone, polysulfide, and acrylic sealants.

Resistant to oils, mild acids, alkalis, and construction chemicals.

H3: UV Stability

Protected when embedded inside joints.

Maintains long-term stability.

H2: Installation Advantages

H3: Easy Handling

Lightweight and flexible.

No special tools required.

H3: Fast Installation

Push-fit installation reduces labor time.

Speeds up project execution.

H3: Clean Application

Does not contaminate sealant.

No dust or fibers released.

H2: Typical Application Areas

H3: Concrete Expansion Joints

Industrial floors, slabs, bridges, pavements.

H3: Building Envelope Joints

Curtain walls, façades, precast panels.

H3: Window & Door Sealing

Perimeter sealing of frames.

H3: Roofing & Waterproofing Joints

Movement joints in membranes.

H3: Infrastructure Projects

Tunnels, highways, airports.

H2: Available Sizes & Packaging

Available in multiple diameters from small to large joints.

Supplied in continuous coils or cut lengths.

Custom sizes available.

H2: Storage & Handling Guidelines

Store in dry shaded area.

Avoid direct sunlight.

Keep away from sharp objects.

H2: Advantages of Robust Backer Rod

-

Precise sealant depth control

-

Prevents premature sealant failure

-

Reduces sealant consumption

-

Waterproof and chemical resistant

-

Easy installation

-

Long service life

-

Cost-effective solution

-

Compatible with all major sealants

H2: Why Choose Robust Backer Rod?

Robust quality assurance

Consistent density and diameter

Trusted by professionals

Reliable supply and technical support

H2: Conclusion

Robust Backer Rod delivers superior joint sealing performance, long-term durability, and installation efficiency for all construction applications.

Robust Backer Rod | Professional Joint Filling & Sealant Performance System

Meta Description:

Robust Backer Rod is a high-performance closed-cell polyethylene foam rod used to control sealant depth, prevent three-sided adhesion, improve waterproofing efficiency, and extend the service life of construction joints in concrete and building structures.

H2: Product Overview of Robust Backer Rod

Robust Backer Rod is a compressible, flexible joint backing material manufactured from premium-grade closed-cell polyethylene foam.

It is installed inside joints before sealant application to provide correct joint geometry, regulate sealant depth, and enhance long-term sealing performance.

This product is widely used in expansion joints, control joints, glazing systems, façade panels, concrete pavements, bridges, basements, industrial floors, and waterproofing systems.

Its primary purpose is to ensure that sealants function properly by avoiding excessive bonding and allowing controlled movement.

Robust Backer Rod improves construction quality, reduces material waste, and increases the durability of joint sealing systems.

H2: Material Composition and Structural Engineering

H3: Closed-Cell Polyethylene Foam Core

Robust Backer Rod is produced using high-density polyethylene foam technology with millions of sealed micro-cells.

These closed cells prevent water absorption, air penetration, and chemical ingress.

The foam structure provides excellent elasticity, allowing the rod to compress during installation and recover its original shape inside the joint.

H3: Precision Diameter Manufacturing

Each rod is manufactured with accurate diameter tolerance to ensure consistent joint filling and reliable sealant depth control.

Uniform diameter ensures predictable sealant performance across large projects.

H3: Lightweight and Non-Degradable Material

The foam does not rot, decay, or support mold growth.

It remains dimensionally stable throughout its service life.

H2: Functional Benefits in Joint Sealing Systems

H3: Sealant Depth Regulation

Backer rod defines the correct thickness of sealant.

This prevents excessive sealant usage and ensures flexibility.

Correct depth improves elasticity and reduces cracking risk.

H3: Prevention of Three-Sided Adhesion

Sealant must adhere only to two sides of the joint.

Backer rod prevents bonding to the joint bottom.

This allows proper expansion and contraction movement.

H3: Sealant Shape Optimization

Backer rod helps form the ideal hourglass profile of sealant.

This profile distributes stress evenly and improves durability.

H3: Movement Accommodation

Supports thermal movement, vibration, and structural shifts.

Prevents premature sealant failure.

H2: Mechanical Performance Properties

H3: Compression Recovery

Maintains shape after repeated compression.

Ensures consistent joint support.

H3: Tensile Strength

Resists tearing during installation.

Handles rough concrete edges.

H3: Flexibility

Adapts easily to uneven joints and curved surfaces.

H3: Temperature Resistance

Performs reliably in extreme hot and cold climates.

H2: Chemical and Environmental Resistance

H3: Water Resistance

Zero water absorption prevents swelling and degradation.

H3: Chemical Compatibility

Compatible with polyurethane, silicone, polysulfide, acrylic, and hybrid sealants.

Resists oils, alkalis, mild acids, and construction chemicals.

H3: UV Stability

Protected when embedded in joints.

Maintains long-term performance.

H2: Installation Guidelines and Best Practices

H3: Joint Preparation

Clean joint surfaces from dust, oil, and loose particles.

H3: Correct Rod Size Selection

Choose rod diameter 25–30% larger than joint width for compression fit.

H3: Installation Method

Insert rod using blunt tools.

Avoid puncturing or stretching the foam.

H3: Sealant Application

Apply sealant uniformly over backer rod.

H2: Typical Applications

H3: Concrete Expansion Joints

Roads, bridges, slabs, industrial floors.

H3: Building Façade Systems

Curtain walls, cladding joints, precast panels.

H3: Window and Door Perimeters

Air and water sealing.

H3: Roofing & Waterproofing Systems

Movement joints in membranes.

H3: Infrastructure Projects

Tunnels, airports, water tanks.

H2: Available Sizes and Packaging

Diameters from small to large joints.

Supplied in coils or lengths.

Custom packaging available.

H2: Storage and Handling

Store in dry shaded area.

Protect from sharp objects.

Avoid prolonged UV exposure.

H2: Advantages of Robust Backer Rod

-

Improves sealant durability

-

Reduces sealant consumption

-

Waterproof and chemical resistant

-

Easy and fast installation

-

Long service life

-

Cost-effective solution

-

Compatible with all sealants

H2: Why Choose Robust Backer Rod?

Reliable quality control

Consistent manufacturing standards

Strong technical support

Trusted by construction professionals

H2: Conclusion

Robust Backer Rod delivers superior joint sealing performance, long-term durability, and cost efficiency for all construction and infrastructure projects.

Robust Backer Rod | Professional Joint Filling & Sealant Performance System

Meta Description:

Robust Backer Rod is a high-performance closed-cell polyethylene foam rod used to control sealant depth, prevent three-sided adhesion, improve waterproofing efficiency, and extend the service life of construction joints in concrete and building structures.

H2: Product Overview of Robust Backer Rod

Robust Backer Rod is a compressible, flexible joint backing material manufactured from premium-grade closed-cell polyethylene foam.

It is installed inside joints before sealant application to provide correct joint geometry, regulate sealant depth, and enhance long-term sealing performance.

This product is widely used in expansion joints, control joints, glazing systems, façade panels, concrete pavements, bridges, basements, industrial floors, and waterproofing systems.

Its primary purpose is to ensure that sealants function properly by avoiding excessive bonding and allowing controlled movement.

Robust Backer Rod improves construction quality, reduces material waste, and increases the durability of joint sealing systems.

H2: Material Composition and Structural Engineering

H3: Closed-Cell Polyethylene Foam Core

Robust Backer Rod is produced using high-density polyethylene foam technology with millions of sealed micro-cells.

These closed cells prevent water absorption, air penetration, and chemical ingress.

The foam structure provides excellent elasticity, allowing the rod to compress during installation and recover its original shape inside the joint.

H3: Precision Diameter Manufacturing

Each rod is manufactured with accurate diameter tolerance to ensure consistent joint filling and reliable sealant depth control.

Uniform diameter ensures predictable sealant performance across large projects.

H3: Lightweight and Non-Degradable Material

The foam does not rot, decay, or support mold growth.

It remains dimensionally stable throughout its service life.

H2: Functional Benefits in Joint Sealing Systems

H3: Sealant Depth Regulation

Backer rod defines the correct thickness of sealant.

This prevents excessive sealant usage and ensures flexibility.

Correct depth improves elasticity and reduces cracking risk.

H3: Prevention of Three-Sided Adhesion

Sealant must adhere only to two sides of the joint.

Backer rod prevents bonding to the joint bottom.

This allows proper expansion and contraction movement.

H3: Sealant Shape Optimization

Backer rod helps form the ideal hourglass profile of sealant.

This profile distributes stress evenly and improves durability.

H3: Movement Accommodation

Supports thermal movement, vibration, and structural shifts.

Prevents premature sealant failure.

H2: Mechanical Performance Properties

H3: Compression Recovery

Maintains shape after repeated compression.

Ensures consistent joint support.

H3: Tensile Strength

Resists tearing during installation.

Handles rough concrete edges.

H3: Flexibility

Adapts easily to uneven joints and curved surfaces.

H3: Temperature Resistance

Performs reliably in extreme hot and cold climates.

H2: Chemical and Environmental Resistance

H3: Water Resistance

Zero water absorption prevents swelling and degradation.

H3: Chemical Compatibility

Compatible with polyurethane, silicone, polysulfide, acrylic, and hybrid sealants.

Resists oils, alkalis, mild acids, and construction chemicals.

H3: UV Stability

Protected when embedded in joints.

Maintains long-term performance.

H2: Installation Guidelines and Best Practices

H3: Joint Preparation

Clean joint surfaces from dust, oil, and loose particles.

H3: Correct Rod Size Selection

Choose rod diameter 25–30% larger than joint width for compression fit.

H3: Installation Method

Insert rod using blunt tools.

Avoid puncturing or stretching the foam.

H3: Sealant Application

Apply sealant uniformly over backer rod.

H2: Typical Applications

H3: Concrete Expansion Joints

Roads, bridges, slabs, industrial floors.

H3: Building Façade Systems

Curtain walls, cladding joints, precast panels.

H3: Window and Door Perimeters

Air and water sealing.

H3: Roofing & Waterproofing Systems

Movement joints in membranes.

H3: Infrastructure Projects

Tunnels, airports, water tanks.

H2: Available Sizes and Packaging

Diameters from small to large joints.

Supplied in coils or lengths.

Custom packaging available.

H2: Storage and Handling

Store in dry shaded area.

Protect from sharp objects.

Avoid prolonged UV exposure.

H2: Advantages of Robust Backer Rod

-

Improves sealant durability

-

Reduces sealant consumption

-

Waterproof and chemical resistant

-

Easy and fast installation

-

Long service life

-

Cost-effective solution

-

Compatible with all sealants

H2: Why Choose Robust Backer Rod?

Reliable quality control

Consistent manufacturing standards

Strong technical support

Trusted by construction professionals

H2: Conclusion

Robust Backer Rod delivers superior joint sealing performance, long-term durability, and cost efficiency for all construction and infrastructure projects.

Robust Backer Rod | Premium Joint Filling & Sealant Support Solution

Meta Description:

Robust Backer Rod is a high-quality closed-cell polyethylene foam rod designed to control sealant depth, improve joint performance, and provide long-lasting waterproof sealing in construction expansion joints and concrete works.

H2: What is Robust Backer Rod?

Robust Backer Rod is a flexible, compressible foam rod made from closed-cell polyethylene material.

It is installed inside joints before applying sealant to control joint depth, support sealant shape, and prevent three-sided adhesion.

Backer rods are essential in expansion joints, control joints, glazing joints, precast panels, concrete slabs, and façade systems.

They improve sealant performance, extend service life, and reduce material consumption.

H2: Material Composition & Structure

H3: Closed-Cell Polyethylene Foam

Robust Backer Rod is manufactured from high-density polyethylene foam with a closed-cell structure.

This ensures low water absorption, excellent flexibility, and chemical resistance.

H3: Round Uniform Profile

The rod has consistent diameter for uniform joint filling and easy installation.

Maintains compression and shape recovery.

H3: Lightweight and Non-Absorbent

Does not absorb moisture, rot, or degrade.

Safe for indoor and outdoor use.

H2: Key Functions of Robust Backer Rod

H3: Controls Sealant Depth

Ensures proper sealant thickness and joint geometry.

Prevents excessive sealant usage and saves cost.

H3: Prevents Three-Sided Adhesion

Allows sealant to bond only on two sides for proper movement.

Prevents premature cracking and failure.

H3: Provides Joint Flexibility

Supports expansion and contraction movement.

Enhances durability of sealant joints.

H3: Acts as Bond Breaker

Prevents sealant from sticking to joint bottom.

H2: Performance Features

H3: Water Resistance

Closed-cell structure prevents water penetration.

H3: Chemical Resistance

Resists oils, acids, alkalis, and construction chemicals.

H3: Temperature Stability

Performs well in hot and cold climates.

H3: Compression Recovery

Maintains shape after compression.

H2: Applications of Robust Backer Rod

H3: Expansion Joints

Concrete slabs, bridges, pavements, basements.

H3: Window & Door Perimeters

Improves sealing performance.

H3: Precast Panels & Facades

Controls joint depth and sealing.

H3: Flooring & Industrial Joints

Supports movement joints.

H3: Roofing & Waterproofing Systems

Enhances joint sealing durability.

H2: Installation Guidelines

H3: Joint Preparation

Clean joint from dust and debris.

H3: Backer Rod Placement

Insert using blunt tool.

H3: Sealant Application

Apply sealant over rod.

H2: Available Sizes

Multiple diameters available.

Custom sizes on request.

H2: Advantages of Robust Backer Rod

-

Improves sealant life

-

Reduces sealant consumption

-

Waterproof and durable

-

Easy installation

-

Cost-effective

-

Chemical resistant

-

Suitable for indoor and outdoor use

H2: Why Choose Robust Backer Rod?

Reliable quality.

Consistent performance.

Trusted by professionals.

H2: Conclusion

Robust Backer Rod ensures professional joint sealing performance, durability, and cost efficiency in all construction applications.