Reliable Expansion Joint Sealing | Chemical-Resistant Water Stopper for Concrete Works

Reliable Expansion Joint Sealing is essential for durable and waterproof concrete structures.

Chemical-Resistant Water Stopper systems are designed to block water and aggressive agents at joint locations.

Concrete structures naturally expand and contract due to temperature changes.

Expansion joints allow this movement while maintaining structural stability.

Without proper joint sealing, water and chemicals can penetrate concrete.

This leads to corrosion, cracking, and long-term structural damage.

H2: What Is a Chemical-Resistant Water Stopper

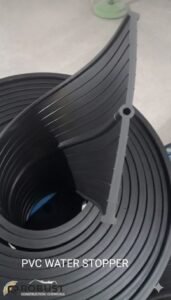

A chemical-resistant water stopper is a flexible sealing profile embedded in concrete joints.

It blocks the flow of water, chemicals, and aggressive liquids through expansion joints.

These water stoppers are manufactured using high-grade PVC or synthetic rubber.

They resist oils, acids, alkalis, and industrial chemicals.

Their flexibility allows them to absorb structural movement.

This prevents cracking and leakage at joint locations.

H3: Material Composition and Properties

Chemical-resistant water stoppers are made from durable polymer compounds.

These compounds maintain elasticity under harsh conditions.

They resist degradation caused by chemicals and moisture.

This ensures consistent performance in industrial environments.

The material does not become brittle over time.

It maintains sealing efficiency throughout structure lifespan.

H3: Profile Designs for Expansion Joints

Central bulb profiles are used in expansion joints.

They allow movement while maintaining watertight sealing.

Ribbed edges improve bonding with surrounding concrete.

This prevents water bypass through joint edges.

Different widths and thicknesses suit various joint designs.

Correct profile selection ensures effective joint protection.

H2: Importance of Expansion Joint Sealing in Concrete Works

Expansion joints accommodate movement caused by temperature variation.

They prevent uncontrolled cracking in concrete structures.

However, joints also create potential water paths.

Without sealing, joints become primary leakage points.

Water stoppers seal these movement joints internally.

They provide permanent waterproof protection.

H3: Protection Against Structural Damage

Water and chemicals entering joints damage concrete and steel.

This causes corrosion and loss of structural strength.

Water stoppers block harmful agents at joint level.

They protect reinforcement and concrete from deterioration.

This improves overall durability of structures.

It extends service life significantly.

H3: Maintaining Functional Performance

Industrial and commercial buildings require leak-free floors and walls.

Water intrusion disrupts operations and damages equipment.

Joint sealing ensures dry and safe working environments.

It protects machinery and stored materials.

Reliable sealing supports uninterrupted facility operations.

It reduces downtime and repair costs.

H2: Applications of Chemical-Resistant Water Stoppers

Chemical-resistant water stoppers are used in various construction sectors.

They provide joint sealing where chemical exposure is expected.

They are essential in industrial, commercial, and infrastructure projects.

They protect joints from moisture and chemical attack.

H3: Industrial Floors and Processing Plants

Factories often use chemicals and wash-down systems.

Expansion joints are exposed to aggressive liquids.

Water stoppers prevent chemical penetration into concrete.

They protect structural integrity and surface finishes.

This ensures long-lasting industrial flooring systems.

It reduces maintenance frequency.

H3: Wastewater Treatment Plants

Treatment facilities handle corrosive liquids and gases.

Concrete joints require chemical-resistant sealing.

Water stoppers block infiltration and exfiltration.

They protect surrounding environment from contamination.

This supports safe and compliant plant operations.

It improves environmental protection.

H3: Basements and Underground Structures

Underground structures face groundwater and soil chemicals.

Joint sealing is critical for waterproof performance.

Chemical-resistant water stoppers protect against seepage.

They ensure dry and durable underground spaces.

This improves usability and safety of basements.

It supports long-term building reliability.

H2: Advantages of Chemical-Resistant Water Stopper Systems

Chemical-resistant water stoppers offer superior joint protection.

They provide both waterproofing and chemical sealing.

They are flexible and strong at the same time.

They adapt to joint movement without losing seal.

H3: Resistance to Aggressive Chemicals

These water stoppers resist acids, oils, and alkalis.

They maintain performance in industrial environments.

Chemical resistance prevents material degradation.

This ensures long-term joint sealing reliability.

This feature is critical in processing plants.

It protects structures from chemical corrosion.

H3: High Flexibility and Movement Accommodation

Expansion joints move due to temperature and load changes.

Water stoppers absorb this movement safely.

Central bulb profiles expand and compress with joint movement.

This maintains watertight sealing.

Flexibility prevents cracking of surrounding concrete.

It improves structural stability.

H2: Installation Process for Expansion Joint Water Stoppers

Correct installation is essential for performance.

Improper placement reduces sealing efficiency.

Water stoppers are positioned at joint center.

Half profile is embedded in first concrete pour.

Remaining half is embedded during second pour.

This creates continuous internal sealing.

H3: Fixing and Alignment Techniques

Water stoppers must be securely fixed before pouring.

This prevents displacement during concrete placement.

Proper alignment ensures central positioning.

This maximizes joint movement capacity.

Fixing clips and wires are commonly used.

They hold profile in correct position.

H3: Welding and Joint Connections

Profile joints must be heat welded.

This creates continuous sealing across joint intersections.

Proper welding maintains material strength.

It prevents leakage through connection points.

Trained workers should perform welding.

This ensures reliable waterproofing performance.

H2: Compatibility with Other Joint Sealing Systems

Water stoppers work alongside surface joint sealants.

They provide internal sealing support.

Surface sealants protect joint from dirt and debris.

Water stoppers protect against internal water pressure.

Dual systems provide maximum joint protection.

They are recommended for critical structures.

H3: Use with PU Joint Sealants

PU sealants protect joint surfaces from moisture.

Water stoppers block internal water paths.

Together they provide complete joint protection.

They reduce leakage risk significantly.

This combination improves joint durability.

It supports long-term performance.

H3: Integration with Waterproofing Membranes

Membranes protect surfaces from water penetration.

Water stoppers protect joint interiors.

Combined systems ensure waterproof continuity.

They eliminate weak points in waterproofing.

This is essential in basements and tunnels.

It ensures reliable protection.

H2: Performance in Harsh Environmental Conditions

Chemical-resistant water stoppers perform in extreme environments.

They tolerate temperature changes and chemical exposure.

They maintain flexibility in hot and cold conditions.

This ensures sealing integrity year-round.

They resist UV exposure when partially exposed.

This protects joint areas near surface.

H3: High Temperature Stability

Water stoppers do not soften under heat.

They maintain shape and sealing performance.

This is important in industrial floors.

It ensures consistent joint protection.

Temperature stability prevents joint failure.

It supports structural reliability.

H3: Resistance to Soil and Groundwater Chemicals

Soil contains salts and chemicals.

These can attack unprotected materials.

Chemical-resistant water stoppers resist such attacks.

They protect underground joints effectively.

This improves durability of foundations.

It reduces long-term maintenance costs.

H2: Why Use Chemical-Resistant Water Stoppers in Pakistan

Pakistan construction faces varied environmental conditions.

Industrial zones involve chemical exposure risks.

Urban areas have high groundwater levels.

Joint sealing is essential for waterproof basements.

Chemical-resistant water stoppers provide reliable solution.

They support durable infrastructure development.

H3: Industrial Growth and Infrastructure Demand

Factories and processing plants are increasing.

Reliable joint sealing is required for compliance.

Water stoppers protect concrete from chemical damage.

They ensure long service life of facilities.

This supports industrial productivity.

It reduces operational disruptions.

H3: Suitable for Residential and Commercial Buildings

Basements and water tanks are common in modern buildings.

Joint sealing prevents leakage and dampness.

Chemical-resistant water stoppers protect against soil chemicals.

They maintain dry and safe indoor environments.

This improves property value and comfort.

It supports quality construction standards.

H2: Maintenance and Inspection of Joint Sealing Systems

Water stoppers are maintenance-free once installed.

They are protected within concrete structure.

Surface joints should be inspected periodically.

This ensures surface sealants remain intact.

If surface cracks appear, external repairs can be done.

Water stoppers continue internal protection.

H3: Repair Strategies for Joint Leakage

Injection grouting can seal surface cracks.

Water stoppers remain effective internally.

This provides double protection against leakage.

It prevents major structural damage.

Regular inspections reduce repair costs.

They ensure continuous waterproofing.

H3: Long Service Life Benefits

Water stoppers last as long as concrete structure.

They do not require replacement.

Long life reduces lifecycle cost.

It improves investment efficiency.

This makes water stoppers cost-effective solution.

It supports sustainable construction practices.

H2: Conclusion – Reliable Solution for Expansion Joint Sealing

Reliable Expansion Joint Sealing is critical for durable concrete structures.

Chemical-Resistant Water Stoppers provide permanent joint protection.

They block water and chemicals at joint locations.

They protect reinforcement and concrete from deterioration.

Their flexibility, durability, and resistance make them ideal for industrial and building projects.

They support long-term structural safety and waterproof performance.

For construction and waterproofing suppliers in Pakistan,

Chemical-resistant water stoppers are essential products for quality concrete works.

Reliable Expansion Joint Sealing | Chemical-Resistant Water Stopper for Concrete Works

Reliable Expansion Joint Sealing is essential for durable and waterproof concrete structures.

Chemical-Resistant Water Stopper systems are designed to block water and aggressive agents at joint locations.

Concrete structures naturally expand and contract due to temperature changes.

Expansion joints allow this movement while maintaining structural stability.

Without proper joint sealing, water and chemicals can penetrate concrete.

This leads to corrosion, cracking, and long-term structural damage.

H2: What Is a Chemical-Resistant Water Stopper

A chemical-resistant water stopper is a flexible sealing profile embedded in concrete joints.

It blocks the flow of water, chemicals, and aggressive liquids through expansion joints.

These water stoppers are manufactured using high-grade PVC or synthetic rubber.

They resist oils, acids, alkalis, and industrial chemicals.

Their flexibility allows them to absorb structural movement.

This prevents cracking and leakage at joint locations.

H3: Material Composition and Properties

Chemical-resistant water stoppers are made from durable polymer compounds.

These compounds maintain elasticity under harsh conditions.

They resist degradation caused by chemicals and moisture.

This ensures consistent performance in industrial environments.

The material does not become brittle over time.

It maintains sealing efficiency throughout structure lifespan.

H3: Profile Designs for Expansion Joints

Central bulb profiles are used in expansion joints.

They allow movement while maintaining watertight sealing.

Ribbed edges improve bonding with surrounding concrete.

This prevents water bypass through joint edges.

Different widths and thicknesses suit various joint designs.

Correct profile selection ensures effective joint protection.

H2: Importance of Expansion Joint Sealing in Concrete Works

Expansion joints accommodate movement caused by temperature variation.

They prevent uncontrolled cracking in concrete structures.

However, joints also create potential water paths.

Without sealing, joints become primary leakage points.

Water stoppers seal these movement joints internally.

They provide permanent waterproof protection.

H3: Protection Against Structural Damage

Water and chemicals entering joints damage concrete and steel.

This causes corrosion and loss of structural strength.

Water stoppers block harmful agents at joint level.

They protect reinforcement and concrete from deterioration.

This improves overall durability of structures.

It extends service life significantly.

H3: Maintaining Functional Performance

Industrial and commercial buildings require leak-free floors and walls.

Water intrusion disrupts operations and damages equipment.

Joint sealing ensures dry and safe working environments.

It protects machinery and stored materials.

Reliable sealing supports uninterrupted facility operations.

It reduces downtime and repair costs.

H2: Applications of Chemical-Resistant Water Stoppers

Chemical-resistant water stoppers are used in various construction sectors.

They provide joint sealing where chemical exposure is expected.

They are essential in industrial, commercial, and infrastructure projects.

They protect joints from moisture and chemical attack.

H3: Industrial Floors and Processing Plants

Factories often use chemicals and wash-down systems.

Expansion joints are exposed to aggressive liquids.

Water stoppers prevent chemical penetration into concrete.

They protect structural integrity and surface finishes.

This ensures long-lasting industrial flooring systems.

It reduces maintenance frequency.

H3: Wastewater Treatment Plants

Treatment facilities handle corrosive liquids and gases.

Concrete joints require chemical-resistant sealing.

Water stoppers block infiltration and exfiltration.

They protect surrounding environment from contamination.

This supports safe and compliant plant operations.

It improves environmental protection.

H3: Basements and Underground Structures

Underground structures face groundwater and soil chemicals.

Joint sealing is critical for waterproof performance.

Chemical-resistant water stoppers protect against seepage.

They ensure dry and durable underground spaces.

This improves usability and safety of basements.

It supports long-term building reliability.

H2: Advantages of Chemical-Resistant Water Stopper Systems

Chemical-resistant water stoppers offer superior joint protection.

They provide both waterproofing and chemical sealing.

They are flexible and strong at the same time.

They adapt to joint movement without losing seal.

H3: Resistance to Aggressive Chemicals

These water stoppers resist acids, oils, and alkalis.

They maintain performance in industrial environments.

Chemical resistance prevents material degradation.

This ensures long-term joint sealing reliability.

This feature is critical in processing plants.

It protects structures from chemical corrosion.

H3: High Flexibility and Movement Accommodation

Expansion joints move due to temperature and load changes.

Water stoppers absorb this movement safely.

Central bulb profiles expand and compress with joint movement.

This maintains watertight sealing.

Flexibility prevents cracking of surrounding concrete.

It improves structural stability.

H2: Installation Process for Expansion Joint Water Stoppers

Correct installation is essential for performance.

Improper placement reduces sealing efficiency.

Water stoppers are positioned at joint center.

Half profile is embedded in first concrete pour.

Remaining half is embedded during second pour.

This creates continuous internal sealing.

H3: Fixing and Alignment Techniques

Water stoppers must be securely fixed before pouring.

This prevents displacement during concrete placement.

Proper alignment ensures central positioning.

This maximizes joint movement capacity.

Fixing clips and wires are commonly used.

They hold profile in correct position.

H3: Welding and Joint Connections

Profile joints must be heat welded.

This creates continuous sealing across joint intersections.

Proper welding maintains material strength.

It prevents leakage through connection points.

Trained workers should perform welding.

This ensures reliable waterproofing performance.

H2: Compatibility with Other Joint Sealing Systems

Water stoppers work alongside surface joint sealants.

They provide internal sealing support.

Surface sealants protect joint from dirt and debris.

Water stoppers protect against internal water pressure.

Dual systems provide maximum joint protection.

They are recommended for critical structures.

H3: Use with PU Joint Sealants

PU sealants protect joint surfaces from moisture.

Water stoppers block internal water paths.

Together they provide complete joint protection.

They reduce leakage risk significantly.

This combination improves joint durability.

It supports long-term performance.

H3: Integration with Waterproofing Membranes

Membranes protect surfaces from water penetration.

Water stoppers protect joint interiors.

Combined systems ensure waterproof continuity.

They eliminate weak points in waterproofing.

This is essential in basements and tunnels.

It ensures reliable protection.

H2: Performance in Harsh Environmental Conditions

Chemical-resistant water stoppers perform in extreme environments.

They tolerate temperature changes and chemical exposure.

They maintain flexibility in hot and cold conditions.

This ensures sealing integrity year-round.

They resist UV exposure when partially exposed.

This protects joint areas near surface.

H3: High Temperature Stability

Water stoppers do not soften under heat.

They maintain shape and sealing performance.

This is important in industrial floors.

It ensures consistent joint protection.

Temperature stability prevents joint failure.

It supports structural reliability.

H3: Resistance to Soil and Groundwater Chemicals

Soil contains salts and chemicals.

These can attack unprotected materials.

Chemical-resistant water stoppers resist such attacks.

They protect underground joints effectively.

This improves durability of foundations.

It reduces long-term maintenance costs.

H2: Why Use Chemical-Resistant Water Stoppers in Pakistan

Pakistan construction faces varied environmental conditions.

Industrial zones involve chemical exposure risks.

Urban areas have high groundwater levels.

Joint sealing is essential for waterproof basements.

Chemical-resistant water stoppers provide reliable solution.

They support durable infrastructure development.

H3: Industrial Growth and Infrastructure Demand

Factories and processing plants are increasing.

Reliable joint sealing is required for compliance.

Water stoppers protect concrete from chemical damage.

They ensure long service life of facilities.

This supports industrial productivity.

It reduces operational disruptions.

H3: Suitable for Residential and Commercial Buildings

Basements and water tanks are common in modern buildings.

Joint sealing prevents leakage and dampness.

Chemical-resistant water stoppers protect against soil chemicals.

They maintain dry and safe indoor environments.

This improves property value and comfort.

It supports quality construction standards.

H2: Maintenance and Inspection of Joint Sealing Systems

Water stoppers are maintenance-free once installed.

They are protected within concrete structure.

Surface joints should be inspected periodically.

This ensures surface sealants remain intact.

If surface cracks appear, external repairs can be done.

Water stoppers continue internal protection.

H3: Repair Strategies for Joint Leakage

Injection grouting can seal surface cracks.

Water stoppers remain effective internally.

This provides double protection against leakage.

It prevents major structural damage.

Regular inspections reduce repair costs.

They ensure continuous waterproofing.

H3: Long Service Life Benefits

Water stoppers last as long as concrete structure.

They do not require replacement.

Long life reduces lifecycle cost.

It improves investment efficiency.

This makes water stoppers cost-effective solution.

It supports sustainable construction practices.

H2: Conclusion – Reliable Solution for Expansion Joint Sealing

Reliable Expansion Joint Sealing is critical for durable concrete structures.

Chemical-Resistant Water Stoppers provide permanent joint protection.

They block water and chemicals at joint locations.

They protect reinforcement and concrete from deterioration.

Their flexibility, durability, and resistance make them ideal for industrial and building projects.

They support long-term structural safety and waterproof performance.

For construction and waterproofing suppliers in Pakistan,

Chemical-resistant water stoppers are essential products for quality concrete works.

reliablereliablereliablereliablereliablereliablereliablereliablereliablereliablereliablereliablereliable